The Three-Dimensional Integrity Challenge

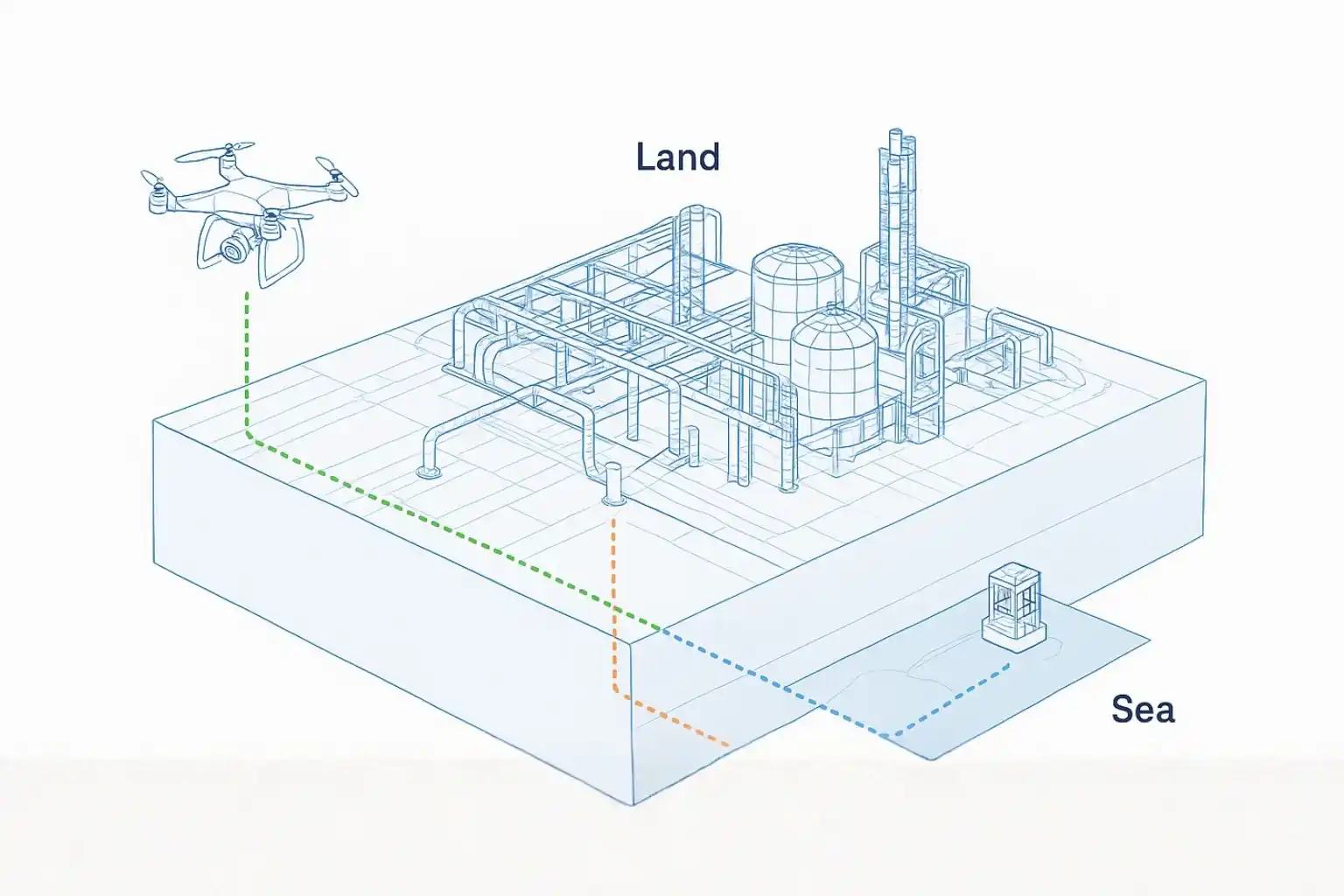

Managing major infrastructure from long-distance pipelines and highways to offshore oil facilities, is a massive task. Asset owners in the MENA region face the immense challenge of maintaining structural health across all three major environments: air (high-altitude assets), land (linear corridors), and sea (submerged foundations).

The traditional approach to managing these assets is severely flawed. Manual surveys on land, reliance on dangerous scaffolding or rope access in the air, and sending human divers into dark, high-risk waters (Sea) are slow, dangerous, and create fragmented data. This leaves asset owners vulnerable to unexpected failure and huge repair costs.

Modern asset management demands a unified solution. It requires a specialized, robotic approach capable of performing objective, centimeter-accurate inspections in every domain. This necessary shift leads to the core of our strategy: full-spectrum asset inspection, utilizing specialized robotics and sensors to create one unified source of truth for the entire asset portfolio.

The Land and Air Domains

The beginning of the full-spectrum approach focuses on digitizing the vast surfaces of land and the complex vertical structures above ground.

I. Land Inspection: Mapping the Foundation and Corridor

Land assets including highways, pipelines, and industrial facilities, suffer from time delays and difficult access points during inspections and surveys. We overcome these challenges through integrated geospatial and robotic solutions.

- LiDAR and Photogrammetry: We use integrated aerial LiDAR systems to create the accurate Digital Terrain Model (DTM) needed for precise road and pipeline routing. Photogrammetry then provides the necessary high-resolution visual context. This initial Topographic Mapping is crucial for checking and verifying design against reality before construction proceeds.

- External Land Inspection: For inspecting rough terrain, checking pipeline integrity, or navigating hazardous ground areas beneath equipment (under-skids), we deploy advanced Deep Robotics platforms. These specialized ground robots access dangerous environments that are too unstable or confined for human inspectors, performing detailed visual and non-contact checks on assets.

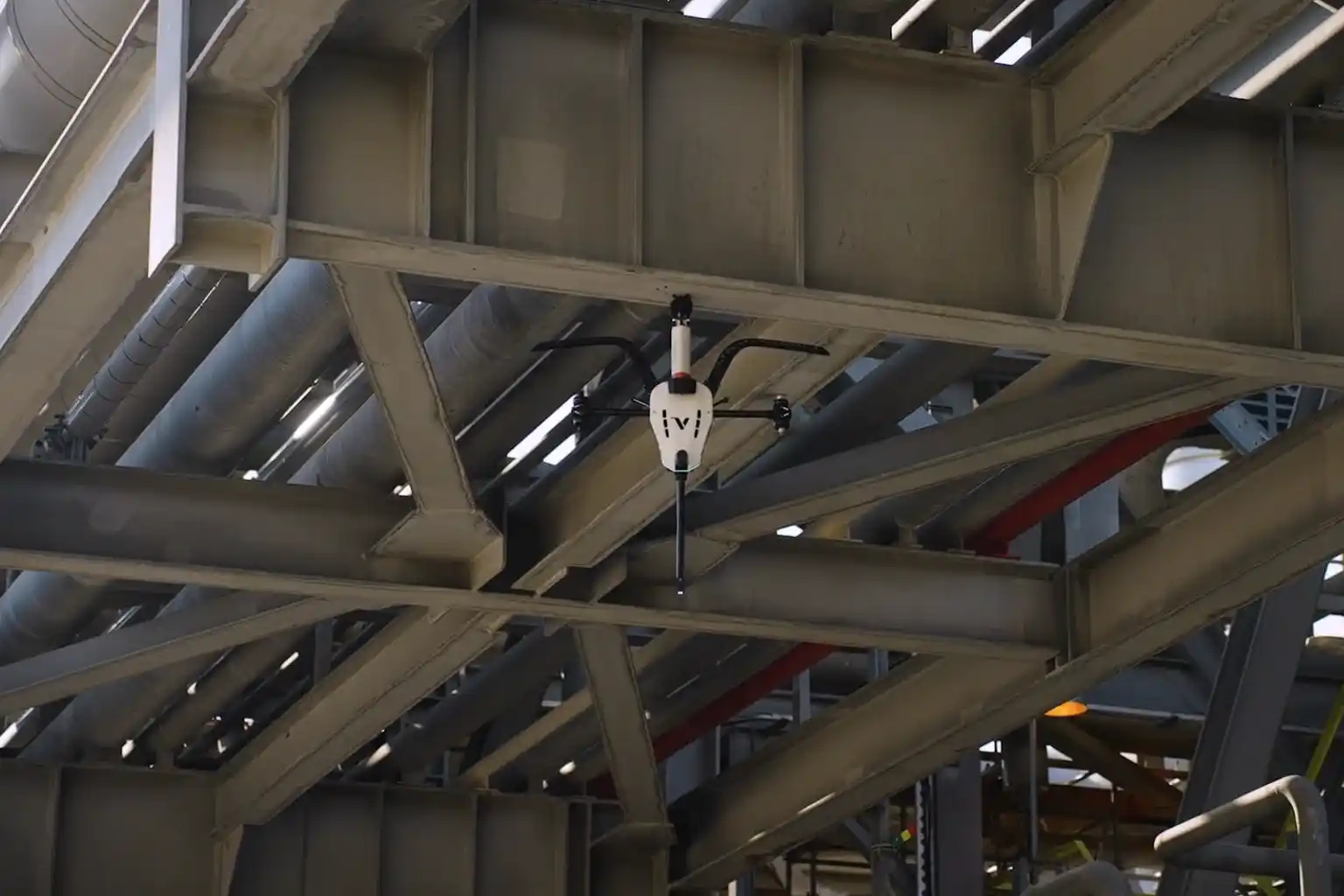

- Internal Land Access (Confined Space): Even internal land structures like large ducts, vessels, or complex pipes require checks. For these challenging spaces where GPS signals fail, we use the Terra Xross 1 drone. This protected, cage-equipped drone flies safely inside these vessels, collecting high-resolution visual data to check for corrosion and structural issues, eliminating the need for human entry into hazardous atmospheres.

- Application: This combined data flow is used for rapid Topographic Mapping, volumetric analysis (earthwork optimization), and early design validation through BIM Integration.

II. Aerial Inspection: Vertical Structures and Confined Spaces

Vertical industrial structures from flare stacks and high piping to storage tanks present significant height risks. Our aerial inspection minimizes human exposure while delivering precise Non-Destructive Testing (NDT).

- Vertical NDT (Contact Inspection): For vital contact-based measurements, we deploy the Voliro T drone. This specialized aerial robot performs external, contact-based UT (Ultrasonic Thickness) Inspection and thermal scanning on challenging vertical and overhead assets, like tank walls and high piping. The Voliro T applies the stable force required to take precise thickness readings, verifying material integrity.

- High-Altitude Visual: We use standard industrial drones to perform rapid, high-resolution visual inspection of tall structures, roofs, and large-area piping, quickly identifying general wear or coating failure.

- Internal Safety (Confined Space): In large industrial vessels and tanks, the Terra Xross 1 drone ensures internal visual checks are performed safely and efficiently, further reducing personnel risk in hazardous, enclosed environments.

The Sea and Synthesis Domains

The third dimension of inspection, the marine environment is the most challenging. Successfully integrating this data creates the core of the predictive strategy.

III. Sea Inspection: Qysea W6 NAVI for Coastal Resilience

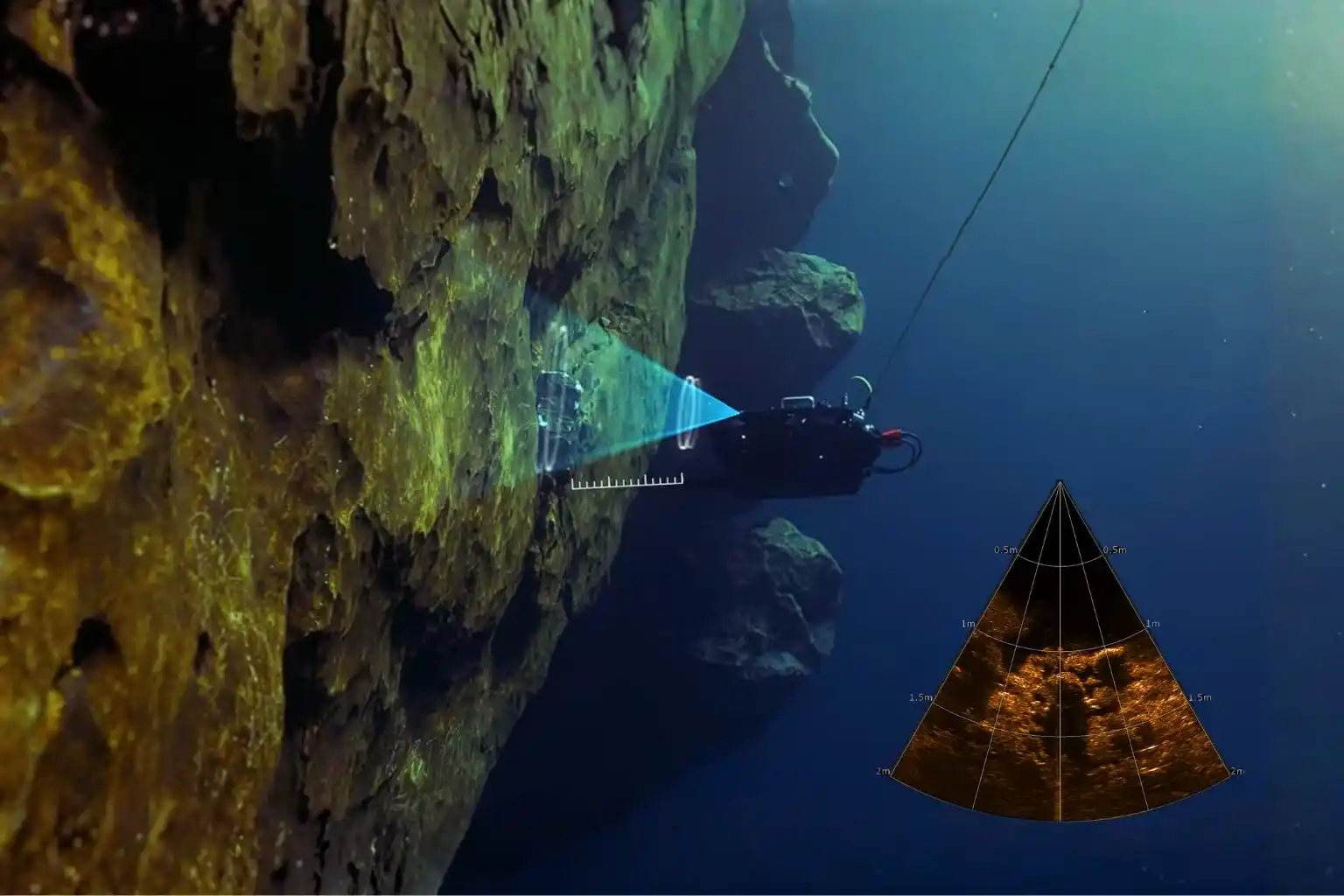

The safety risks, limited visibility, and time constraints of human divers make robotic inspection non-negotiable for subsea assets.

- Problem Solved: Our solution eliminates diver risk, time constraints, and low data quality in subsea environments.

- The Technology (W6 NAVI): We utilize the Qysea Maritime ROV W6 NAVI as the precision platform for underwater inspection. This compact, robust ROV is designed for stability and advanced data acquisition in open sea and port environments.

- Key Capabilities (W6 NAVI): The W6 NAVI provides several vital functions:

- Precision Navigation: It achieves enhanced hovering stability even in high currents, which is essential for accurate data collection near structures.

- Robust Surveys: It supports continuous, automated survey paths for consistent, repeatable data acquisition.

- Sonar and Payloads: It utilizes specialized scanning sonar to navigate in zero visibility conditions and carries modular payloads, including those necessary for subsea NDT and structural measurement.

- Application: The W6 NAVI is critical for inspecting subsea pipelines, performing scour assessment (foundation erosion) around jetties, and checking hull integrity.

IV. The Predictive Synthesis: The Full-Spectrum Digital Twin

The strategic value of full-spectrum asset inspection is realized by merging the data from all three domains (air, land, sea) into one cohesive, predictive platform.

- Data Fusion: We combine the DTMs (Land), the UT measurements (Air), and the sonar/scour data (Sea) into a unified dataset.

- The Digital Twin: This unified dataset creates the Digital Twin, a living, virtual replica of the entire asset portfolio. This advanced digital model allows asset managers to move beyond simple mapping and into true simulation.

- Value and RUL: The Digital Twin enables managers to perform remaining useful life (RUL) calculations and simulate future structural degradation. This unified approach provides objective, predictive maintenance insights, allowing clients to replace emergency spending with proactive, optimized resource allocation across the entire asset portfolio.

Securing Integrity and Leadership

The transition to a digital, holistic inspection strategy is essential for securing operational longevity and supporting Vision 2030’s infrastructure goals. Implement a full-spectrum asset inspection strategy of your infrastructure for long-term safety, efficiency, and predictive control. Let’s Talk!