In the offshore energy sector, what you cannot see can cost you millions. Submerged infrastructure from oilfield wellheads to deep-sea port pilings exists in a state of constant chemical and structural attrition. Saltwater corrosion, biofouling, and extreme pressure work in tandem to create micro-cracks and material fatigue that are often invisible to the naked eye. When these early-stage defects are ignored, they inevitably evolve into catastrophic structural failures or environmental disasters.

The industry is moving away from basic visual observation toward high-precision, data-driven monitoring. To achieve this, operators require an enterprise-grade platform capable of navigating extreme depths while providing the precision of a laboratory. The QYSEA FIFISH PRO W6 is that platform, an industrial-grade ROV designed to turn subsea data into actionable maintenance intelligence.

Technical Superiority of the FIFISH PRO W6

The FIFISH PRO W6 is engineered specifically for harsh deepwater environments where standard ROVs falter. Its technical architecture is built to ensure that “hidden” damage is brought to light with uncompromising clarity.

- Deepwater Performance: Rated for a 350-meter dive depth, the W6 is a true industrial tool for deep-sea port and oilfield operations.

- Patented Propulsion: It features a unique 6 Q-motor system that provides stronger power and anti-current stability, ensuring the drone remains steady even in the unpredictable currents of the open ocean.

- Dual-Camera Visual Intelligence: The W6 utilizes an innovative Dual 4K Camera System. This setup coordinates operation monitoring with motion observation, providing a massive 166° horizontal field of view to ensure operators have a complete picture of the surrounding environment.

- Advanced Navigation and Stability:

- Station Lock: This algorithm locks the ROV’s position in place, preventing drift in complicated water environments to allow for exhaustive inspections of a single weld or joint.

- U-QPS Positioning: The Underwater Quick Positioning System provides real-time ROV location, 3D diving path recording, and point-of-interest (POI) marking, which is essential for mapping recurring corrosion patterns over time.

- Sonar Array: An optional sonar system enables Distance Lock, Altitude Lock, and Collision Avoidance, allowing the ROV to navigate safely near complex subsea structures in zero-visibility conditions.

Precision Tools for Predictive Maintenance

Identifying damage is only the first step; quantifying it is what enables predictive maintenance. The FIFISH PRO W6 is a modular “Swiss Army Knife” for non-destructive testing (NDT).

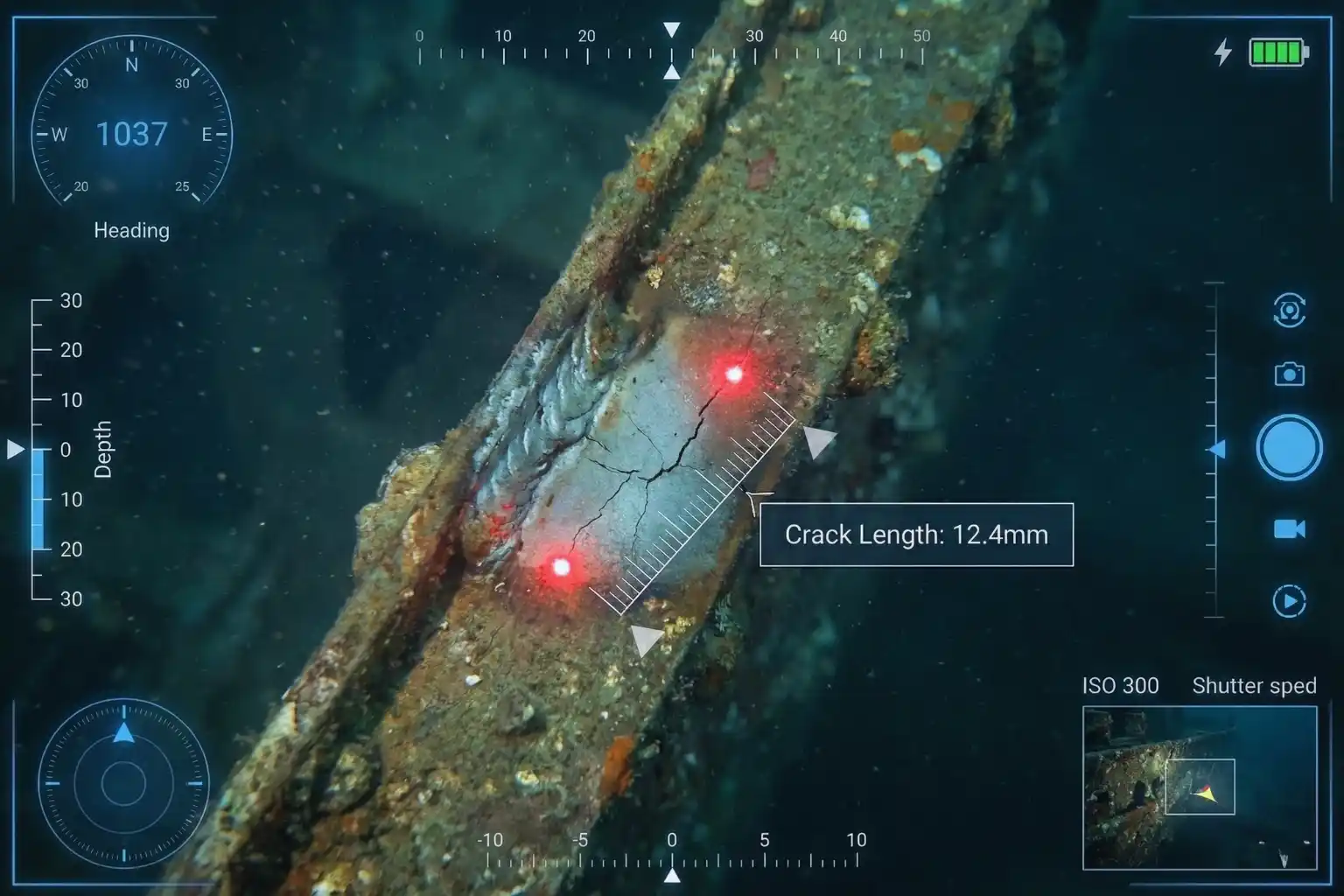

- Measuring the Invisible: The W6 is equipped with a high-precision ruler combination, including a standard Laser Ruler and an optional AR Ruler. These tools allow engineers to accurately measure the scale of cracks and hull damage to identify and prevent further structural degradation.

- Modular Versatility: With 5 Q-Interfaces for payload integration, the W6 can be customized with various industrial tools. It can simultaneously carry a robotic arm with a replaceable claw for sample collection and an imaging sonar for dark-water hull inspections.

- Operational Endurance:

- Removable Battery: The standard 388Wh battery can be swapped quickly on-site and supports a quick-charging mode that reaches 70% in just one hour.

- Onshore Power Supply: For missions requiring “unlimited endurance,” the W6 can be tethered to a miniaturized onshore power system, ensuring it can stay submerged as long as the task requires.

Securing the Submerged Frontier

The FIFISH PRO W6 transforms raw underwater footage into professional work reports. By integrating big data analysis and high-fidelity 3D mapping, it provides offshore managers with a clear roadmap for maintenance, significantly extending the lifecycle of critical assets.

Implementing the W6 Workflow:

- Survey & Record: Use the U-QPS and Dual 4K cameras to create a 3D baseline of your asset.

- Measure & Analyze: Utilize the Laser/AR rulers to monitor the growth of known micro-cracks during recurring audits.

- Act & Maintain: Use the Robotic Arm for light maintenance or to clear biofouling for better visual access.

Contact us and standardize your deepwater maintenance and turn your most critical offshore asset’s threats of the deep into manageable, actionable insights.