In 2026, centimeter-level accuracy is no longer a luxury, it is the prerequisite for the modern industrial site. Whether automating a tractor for row-crop optimization, guiding an excavator on a complex construction project, or deploying autonomous robotic mowers, high-precision geospatial data serves as the invisible backbone of efficiency.

However, the modern operational environment is multi-faceted. A remote agricultural field with zero cellular coverage presents entirely different challenges than an urban construction site where skyscrapers block satellite signals. To solve these specific geospatial barriers, the FJD Trion V10 Series provides three distinct, high-performance GNSS RTK receivers: the V10L, the V10i, and the V10a.

Three Tools, One Ecosystem (Functions & Differences)

To understand the strategic value of the FJD Trion V10 Series, it is essential to look under the hood of each receiver’s specific hardware and communication protocols. While all three share a common mission of high-precision data acquisition, their technical architectures are optimized for different operational frontiers.

1. FJD Trion V10L: The Agile Network Specialist

The V10L is the minimalist powerhouse of the lineup, stripped of bulky internal radios to favor a sleek, ultra-portable form factor without compromising on surveying standards.

- Network-First Architecture: Unlike traditional receivers that require a heavy Base-and-Rover UHF radio setup, the V10L is built primarily as a Network Rover. It leverages an internal high-gain 4G module to connect directly to CORS (Continuously Operating Reference Stations) via the NTRIP protocol. This allows the surveyor to achieve a “Fix” in seconds using only the rover and a handheld controller.

- Optimal Use Case: City-wide utility mapping, municipal infrastructure audits, and landscape planning in areas where cellular signal is ubiquitous.

- Technical Differentiator: It is the lightest in the series, reducing operator fatigue during 8-hour field shifts, yet it still tracks GPS (L1/L2/L5) and BeiDou (B1/B2/B3) with the same millimetric sensitivity as its larger siblings.

2. FJD Trion V10i: The Visual Intelligence Powerhouse

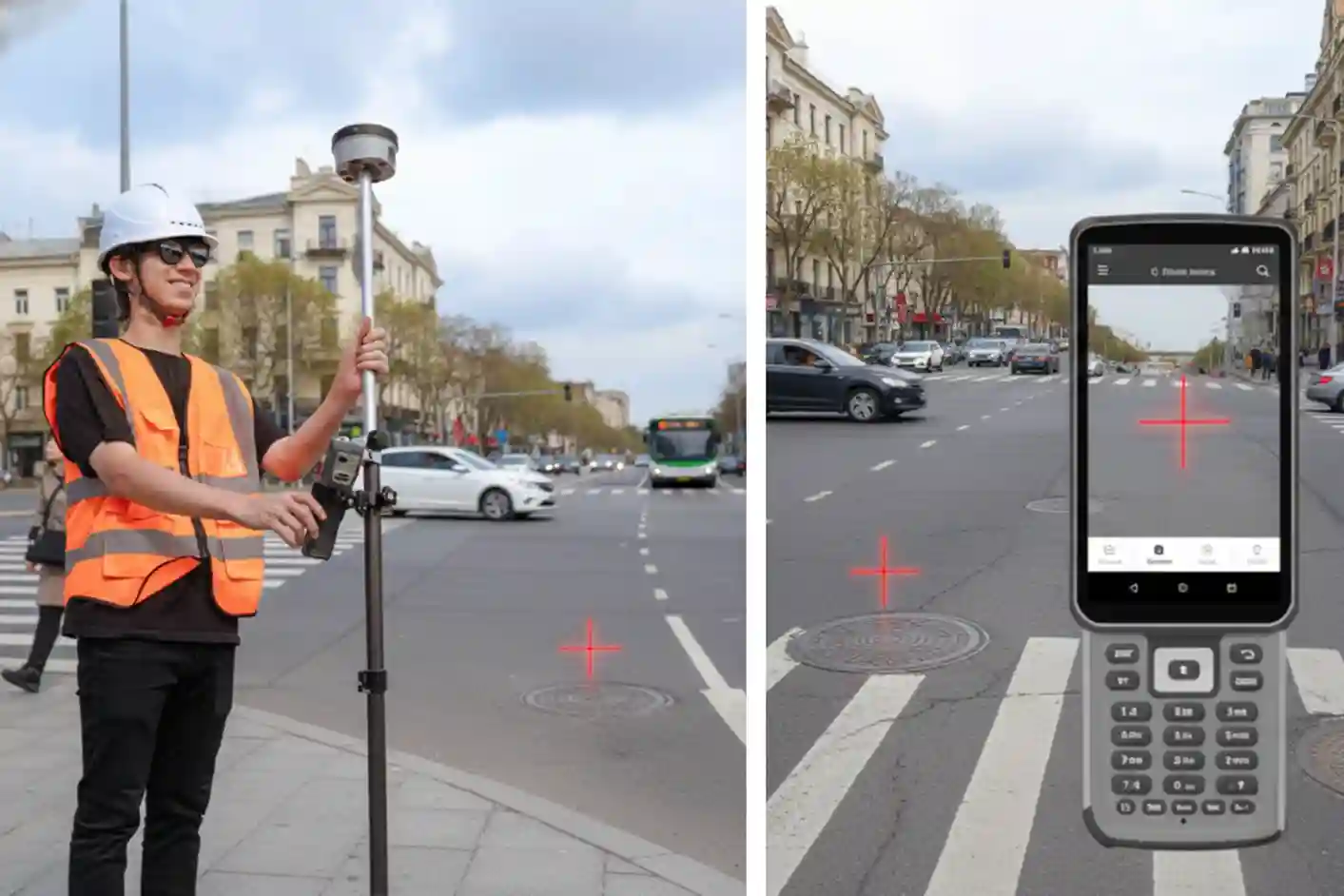

The V10i represents the pinnacle of “Visual-Inertial-GNSS” fusion, adding a literal eye to the receiver to solve the industry’s oldest problem: “The Blind Spot”.

- Integrated HD Vision: The base of the V10i houses a high-definition, low-light camera. This is not just for photography; it powers AR (Augmented Reality) stakeout and visual surveying. In the field, the operator can see the target points overlaid on a live video feed on their controller, making staking tasks significantly more intuitive.

- Measure-from-Distance Capability: The most profound technical advantage of the V10i is its ability to measure points without physical contact. By leveraging Vision-Inertial-GNSS fusion, the software can triangulate coordinates from the camera feed. This means a surveyor can stand 5 meters away from a busy highway lane or a deep construction trench and accurately log a point that would otherwise be dangerous or impossible to reach with a pole.

- Technical Differentiator: It bridges the gap between GNSS and photogrammetry, maintaining precision even when multi-path interference (signals bouncing off tall glass buildings) would typically cause a standard receiver to lose its “Fix”.

3. FJD Trion V10a: The Heavy-Duty, All-Around Performer

The V10a is the “Alpha” tool in the lineup, designed for total autonomy from external infrastructure.

- Dual-Communication Capability: While it supports Network RTK like the V10L, the V10a features a powerful internal UHF radio (transmitter/receiver). This allows it to act as either a base station or a long-range rover. In environments with zero cellular coverage, such as deep desert oilfields or remote agricultural valleys, the V10a establishes its own 5km to 10km “data link” to provide corrections to other machinery.

- Interference Resistance: Built into the V10a are advanced anti-jamming and multi-path suppression algorithms. This makes it the standard for “dirty” signal environments like massive construction sites filled with heavy metal machinery and radio interference from other site teams.

- Technical Differentiator: Its ruggedized shell and high-capacity battery are built for “Frontier Work,” where charging points are rare and the environment is harsh. It is the definitive choice for integrated site backbone roles, providing a stable correction source for FJDynamics autosteer tractors and excavators.

The Shared DNA of FJD Trion Reliability

While the specialized functions of the V10L, V10i, and V10a provide the “personality” for specific projects, their shared engineering core provides the “reliability” that professional surveyors demand. This shared DNA is built on three technical pillars: IMU-driven tilt compensation, multi-frequency constellation tracking, and deep integration into the FJDynamics autonomous ecosystem.

1. The Math of Speed: Calibration-Free IMU Tilt Compensation

One of the most significant bottlenecks in traditional surveying is the “leveling phase,” the seconds spent ensuring the carbon fiber pole is perfectly vertical before a point can be logged. The FJD Trion series eliminates this entirely through a high-grade Inertial Measurement Unit (IMU).

- Real-Time Vector Calculation: The integrated IMU continuously tracks the receiver’s orientation, pitch, and roll at high refresh rates. It uses complex algorithms to calculate the exact distance between the antenna’s phase center and the tip of the pole, regardless of the angle.

- 60° Operational Freedom: Field operators can capture accurate, survey-grade points even when the pole is tilted at up to 60°. This is critical when measuring corners of buildings, utility poles, or the edges of deep excavation pits where standing directly over the point is impossible or unsafe.

- Calibration-Free Readiness: Unlike older generations of tilt-compensated GNSS, the Trion series is “initialization-free”. The IMU stays active and calibrated while the operator walks, allowing for immediate point capture the moment the pole tip touches the ground.

2. Multi-Frequency “Fast Fix” Constellation Tracking

In the industrial environments of 2026, signal reliability is the difference between a productive day and an expensive delay. The Trion series features a 1408-channel GNSS board capable of simultaneous tracking across all global navigation constellations.

- Total Frequency Coverage: The receivers track GPS (L1/L2/L5), GLONASS (G1/G2/G3), BeiDou (B1/B2/B3), Galileo (E1/E5a/E5b), and QZSS (L1/L2/L5).

- Rapid Cold-Start Performance: By tracking more satellites than standard receivers (typically 30+ visible at any time), the Trion series achieves a “Fix” in under 10 seconds, even in challenging environments like deep urban canyons.

- Signal Reconstruction Technology: Advanced algorithms work to filter out “multi-path” signals, erroneous data reflected off buildings or equipment, ensuring that the calculated coordinate is accurate within 8mm (Horizontal) and 15mm (Vertical) in RTK mode.

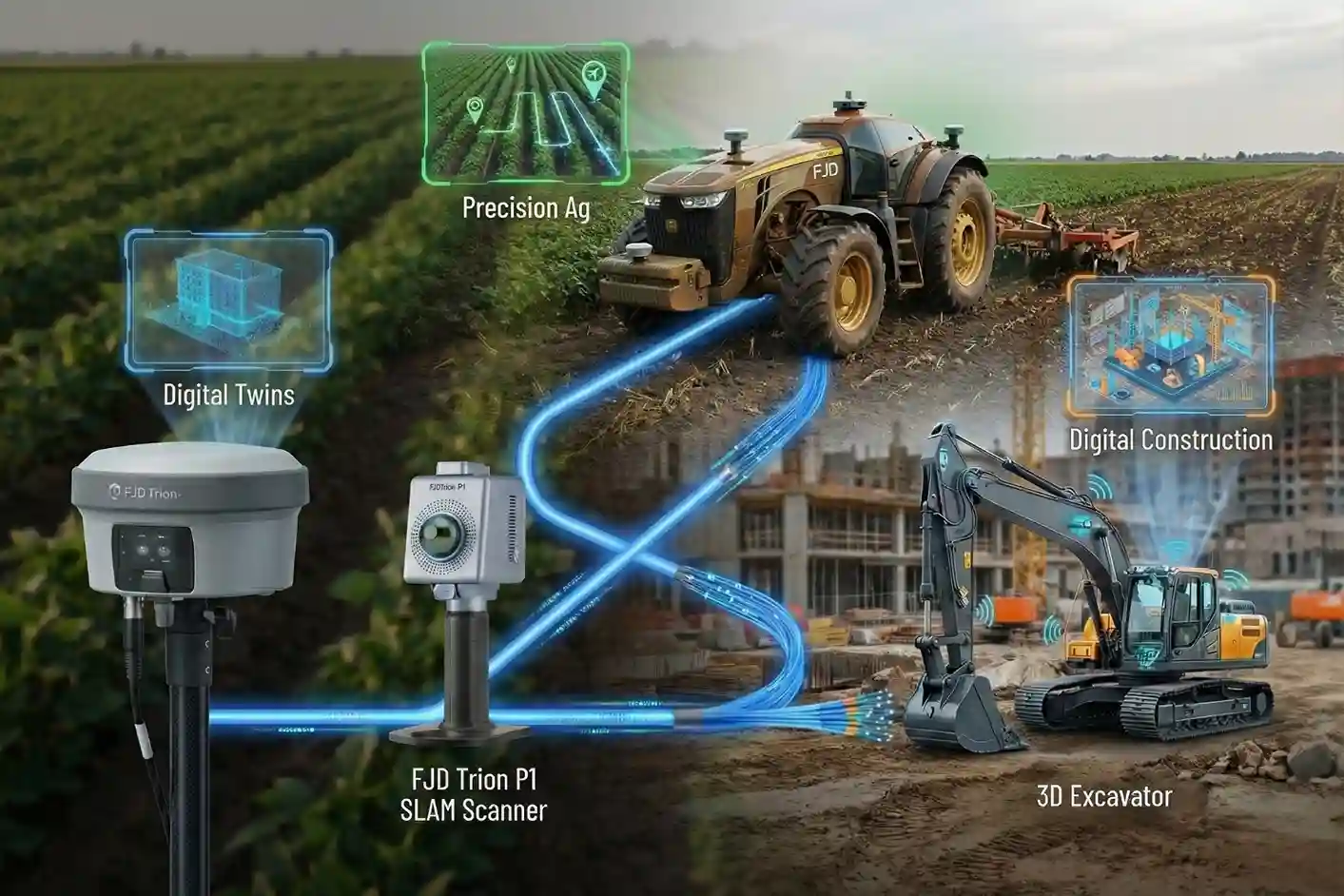

3. The Bridge to Digital Twins: Trion Reality & Build Integration

The reliability of a Trion receiver extends beyond the device itself; it serves as the spatial anchor for a company’s entire digital strategy.

- Trion Reality Workflow: When paired with the Trion P1 SLAM Scanner, the GNSS receivers provide the “georeferencing” data needed to place 3D point clouds accurately on a global map. A surveyor can capture a building’s interior with the P1 and use a V10 receiver to lock that 3D model to real-world coordinates.

- Trion Build Synchronization: For construction firms, the data captured by these receivers feeds directly into Trion Build software. This allows 3D design files (CAD) to be uploaded to an excavator or bulldozer, which then uses the Trion GNSS backbone to guide the blade or bucket with millimeter precision.

- Cloud-Native Collaboration: All data is managed through the FJD Trion Survey app, which supports instant cloud uploads. An engineer in the office can review points logged by a V10i in the field in real-time, drastically reducing the time between “data capture” and “design decision”.

4. Industrial Resilience: Built for the “Spared-Human” Environment

Because these tools are designed to work alongside heavy machinery, they are engineered for extreme durability.

- IP68 Environmental Rating: Each receiver is fully protected against dust ingress and can withstand immersion in water, ensuring performance in Saudi Arabia’s desert sandstorms or sudden tropical downpours.

- Shock & Vibration Resistance: The internal components are shock-mounted to survive a 2-meter pole drop onto hard concrete, a common occurrence in the rugged world of construction and landscaping.

- Intelligent Battery Management: High-capacity internal batteries provide up to 15 hours of continuous operation, ensuring the tool lasts through the longest shift without requiring a field recharge.

Selecting Your Precision Backbone

Selecting the right precision tool is a strategic decision. For city infrastructure, the V10L offers unmatched agility; for complex architectural sites, the V10i bridges the visual gap; and for remote industrial frontiers, the V10a remains the gold standard.

Architect your autonomous future. Contact us today to audit your site requirements and show you, wherever you are, how the FJD Trion RTK ecosystem will bridge your precision and labor gap for 2026.