The EMAT Test: High-Precision NDT Without the Mess

For decades, Ultrasonic Testing (UT) has been the gold standard for verifying asset integrity, yet it remains plagued by operational “friction”. Traditional piezoelectric transducers require a liquid coupling medium, such as water or gel o transmit sound waves into a material. This necessitates extensive surface preparation, including the removal of coatings, rust, and dirt, followed by a tedious cleanup of chemical residues. When these inspections occur at height, the friction multiplies. Organizations must invest heavily in scaffolding or rope access, exposing personnel to high-risk environments while assets remain offline. The Voliro T changes this equation by bringing EMAT (Electromagnetic Acoustic Transducer) technology to the sky, offering the first truly “dry” high-precision NDT solution. The Science of “Touchless” Sound EMAT represents a fundamental shift in how we generate ultrasonic waves. Unlike traditional UT, which relies on mechanical vibrations from a probe, EMAT induces sound waves directly within the metal surface of the asset. The Lorentz Force: The transducer uses a combination of a static magnetic field and a high-frequency alternating current in a coil to trigger the “Lorentz Force” within the material’s surface. Dry Inspections: Because the sound is generated inside the material, no liquid couplant or mechanical coupling is required. Resilience to Contaminants: EMAT thrives on rough, greasy, or oxidized surfaces where traditional gel-based UT would fail. Coating Penetration: The technology can measure wall thickness through existing protective coatings, eliminating the need for abrasive stripping. High-Temperature Performance: EMAT is ideal for inspecting heated assets where standard couplants would instantly boil or evaporate. Technical Synergy of the Voliro T Payload The Voliro T EMAT payload is engineered to deliver laboratory-grade data in the harshest industrial conditions. Precision Specs: The system operates at a high frequency of 3.5–4 MHz, providing a resolution of 0.06 mm. Measurement Range: It accurately measures wall thickness from 2 mm to 150 mm. Operational Flexibility: The probe supports Echo-to-Echo, Single-Echo, and Auto Thickness modes to suit various metallurgical conditions. Lift-off Capability: The sensor maintains a stable signal with a maximum lift-off of 4 mm, allowing it to work over rough textures or thin coatings. Active Contact: Utilizing the Voliro T’s 6-DoF flight architecture, the drone applies stable force to ensure the 30 mm diameter probe remains perfectly positioned against the asset. The Economics of Aerial EMAT Transitioning to an aerial EMAT workflow isn’t just a technical upgrade; it is a massive financial optimization. 4X Faster Results: While manual NDT is slow and labor-intensive, the Voliro T can collect 50–100 high-precision readings per hour. Significant ROI: Case studies indicate that aerial EMAT can save operators over $150,000 per inspection by eliminating scaffolding and minimizing asset downtime. Zero Residue: Because it is a dry process, there is no chemical cleanup required after the flight, protecting sensitive assets from couplant-induced corrosion. Enhanced Safety: The drone removes personnel from hazardous heights, “hot” zones, and toxic environments, conducting the entire survey from the safety of the ground. Implementing the Dry NDT Strategy From elevated flare stacks and large storage tanks to small suppression rings and angled pipeline sections, the Voliro T EMAT system provides a scalable, compliant solution for the digital age. With live A-Scan visualization and immediate data syncing, your engineering team can make structural decisions in real-time. Contact us and architect your autonomous future today. Let us audit your site requirements and deploy the Voliro T EMAT ecosystem wherever you are.

Voliro T: Redefining Structural Integrity Inspections through Aerial NDT

For years, industrial drones have been celebrated as the “eyes in the sky,” providing invaluable visual and thermal data from a safe distance. However, for asset integrity managers, a significant “last mile” remained: the inability to perform physical, contact-based testing without expensive scaffolding, risky rope access, or heavy machinery. Enter the Voliro T. This is not just another drone; it is an advanced aerial robotics platform designed to touch, push, and interact with the world. By bridging the gap between remote sensing and physical interaction, the Voliro T allows organizations to perform complex Non-Destructive Testing (NDT) on live assets with unprecedented speed and safety. A Masterclass in Robotic Agility The technical superiority of the Voliro T is not merely a result of its flight capabilities, but rather its specialized architecture as a 6-degrees-of-freedom (6-DoF) aerial robot. While conventional drones are under-actuated, meaning they must tilt their entire body to move laterally the Voliro T utilizes a unique vectoring thrust system that decouples its orientation from its position. This allows the platform to maintain a specific pose in space while simultaneously applying force, a requirement for high-fidelity NDT data acquisition. Stable Contact and Interaction Mechanics: The platform’s unique design features six tiltable rotors that can vector thrust in any direction. This configuration allows the drone to apply up to 30 N of stable, continuous force against a structure while maintaining a steady flight position. Beyond linear force, the system can generate several N m of torque, enabling the sensor to “seat” itself firmly against curved or irregular surfaces to ensure proper coupling for ultrasonic signals. True 360° Omnidirectional Mobility: The Voliro T is capable of interacting with structures at any angle: vertical walls, horizontal ceilings, or even the undersides of complex industrial geometries. This omnidirectional freedom allows the drone to remain “stuck” to a surface while the airframe itself rotates to avoid obstacles or adjust for shifting wind conditions. Operators can transition from a standard horizontal flight to a vertical “wall-climbing” mode without losing the active sensor link. Assisted Autonomy and GPS-Denied Operations: The Voliro T is equipped with sophisticated assisted autonomy that simplifies the process of making contact with an asset. Automated flight modes handle the precision required for the “approach and touch” phase, reducing the cognitive load on the pilot during high-stakes inspections. These systems are designed to function reliably in GPS-denied environments, such as inside large storage tanks, under steel bridge decks, or within boiler rooms, where traditional satellite-dependent drones would fail to maintain stability. Unmatched Versatility via Open Platform Design: The system is built as an open platform, featuring an interchangeable payload interface that allows for rapid field transitions between various NDT methods. Specific payload designs, such as the 33 cm long EMAT or the 32 cm long UT units, are balanced to work in harmony with the drone’s center of gravity. This versatility ensures that a single flight mission can be reconfigured for different inspection objectives, from screening for relative material loss with PEC to measuring absolute wall thickness with EMAT. The Payloads: Structural Intelligence Delivered Ground-truth data isn’t just a buzzword in 2026; it is a millimetric reality. The Voliro T ecosystem moves beyond simple photography, utilizing a sophisticated suite of swappable payloads designed for specific metallurgical and structural challenges. By integrating these sensors with the platform’s ability to apply $30~N$ of stable force, you gain access to laboratory-grade NDT data from the air. 1. Acoustic & Ultrasonic Intelligence: EMAT vs. UT While both payloads measure wall thickness, their technical applications differ based on the surface condition and the need for speed. EMAT (Electromagnetic Acoustic Transducer): * This 33 cm payload is the “dry-scan” champion, utilizing radially polarized shear waves to measure thickness without any liquid couplant. Operating at a frequency of 3.5–4 MHz, it provides a resolution of $0.06~mm$ across a thickness range of $2–150 mm. Compliant with ASTM E1816-18, it supports Echo-to-Echo, Single-Echo, and Auto Thickness measurement modes, with data visualized via a live A-Scan in the Voliro App. Ultrasonic Transducer (UT) Standard & High-Temp: The standard UT payload uses compression waves and a water-based gel couplant to deliver precision measurements compliant with EN 12668-1 and ISO 16831:2012. For active assets, the High-Temperature UT variant is a mission-critical tool, capable of operating in environments ranging from 0 °C to 260 °C (32–500 °F). Both UT versions feature a 5 MHz dual-element transducer and a natural focus depth of $10 mm, ideal for detecting internal corrosion or erosion in steel structures. 2. Surface Integrity: DFT & PEC Understanding the “skin” of an asset is just as vital as knowing its internal thickness. Dry Film Thickness (DFT): This ultra-lightweight (0.27 kg) payload uses two distinct technical methods: magnetic induction for coating thickness on ferrous metals and eddy current for non-ferrous metals. It offers a measurement range of up to 1.5 mm (60 mils) on ferrous surfaces and is compliant with a massive array of international standards, including ISO 2178, 2360, 2808, and ASTM D 7091. Pulsed Eddy Current (PEC) Sensor: The PEC payload is a powerful screening tool that measures relative volumetric material loss without direct metal contact. It is uniquely capable of measuring through non-ferrous materials such as insulation (rock-wool, blankets), fireproofing, and even marine growth or seawater. With a maximum liftoff of 100 mm, it provides an average wall thickness reading representative of its footprint, making it the perfect tool for identifying “hidden” corrosion under insulation (CUI). 3. Electrical & Wind Infrastructure: The LPS Tester Specifically engineered for the wind energy sector, the LPS (Lightning Protection System) payload ensures turbine blades can survive the elements. Wind Turbine LPS Tester: This system performs 4-wire resistance measurements (Kelvin sensing) to evaluate the full-circuit integrity of a turbine’s lightning protection. The setup includes an 820 ft (250 m) tether cable, allowing for inspections up to a maximum height of 250 m AGL. Compliant with IEC/EN 61400-24, the onboard Mostec micro-ohmmeter provides a resolution of 0.01 MΩ and can measure resistances ranging from 0.001 to 1000

How the FJD Trion V10i Redefines Centimeter Precision

In 2026, the margin for error in industrial surveying has effectively vanished. As we move toward a world of autonomous site governance and high-fidelity digital twins, the 1–2 centimeter accuracy range has transitioned from a specialized requirement to the baseline standard for every project. However, achieving this level of precision is rarely a “plug-and-play” affair. Urban canyons with skyscraper-induced signal multipath, dense foliage that chokes satellite visibility, and dangerous, unreachable points like deep trenches or high-traffic intersections have historically degraded GNSS performance. The FJD Trion V10i breaks these barriers. By fusing 1408-channel satellite tracking with a high-speed IMU and dual-camera visual positioning, it maintains a centimeter-level “Fix” where traditional receivers find only frustration. The Technical Pillars of V10i Accuracy To achieve millimetric precision, the V10i relies on a multi-engine architecture that cross-references satellite data, inertial movement, and visual geometry in real-time. 1. 1408-Channel Multi-Constellation Tracking At the heart of the V10i is a massive 1408-channel GNSS board. While older receivers might track a dozen satellites, the V10i maintains a locked connection with every major global constellation simultaneously: GPS, GLONASS, Galileo, BeiDou, QZSS, and IRNSS. Fast Fix Initialization: This dense satellite coverage allows for a “Cold Start” fix in under 5 seconds, ensuring your team is productive the moment they step onto the site. Interference Mitigation: Utilizing advanced signal processing often powered by the Septentrio Mosaic-X5 chipset. The V10i filters out atmospheric noise and electronic interference, maintaining a stable horizontal accuracy of 8mm + 1ppm. 2. Calibration-Free IMU Tilt Compensation The physics of the V10i allows for a “tilt and go” workflow. Traditional surveying requires the pole to be perfectly vertical (leveling the bubble), which is slow and prone to human error. The 60° Advantage: The V10i’s integration compensates for pole angles up to 60° while maintaining a positioning accuracy of 3 cm. No Manual Leveling: This allows surveyors to measure the corners of buildings, utility foundations, or the bottom of slopes without needing to stand directly over the point or maintain a perfect vertical. 3. Visual Measure: The Eye of Precision The most distinct technical leap of the V10i is its dual-camera system. Dual Global Shutter Cameras: Featuring a 2MP and 5MP camera array, the V10i performs Visual Surveying. By clicking a photo on the controller, the system uses “Vision-Inertial-GNSS” fusion to triangulate coordinates. 3–5 cm Remote Accuracy: This allows for the capture of points that are physically unreachable or dangerous, such as a manhole in the middle of a highway or a point across a river with survey-grade precision from up to several meters away. Optimizing the Workflow for Maximum Precision Centimeter accuracy is not just about the hardware; it is about the “Digital Handshake” between the field and the office. AR Stakeout: Efficiency Reimagined Traditional staking involves “hunting” for a point by following directional arrows. The V10i’s AR (Augmented Reality) stakeout overlays the target point directly onto the live video feed of your controller. This visual guidance allows operators to reach the exact coordinate up to 5X faster than traditional methods, with millimetric precision upon arrival. Site Setup and Correction Links To maintain that 8mm horizontal accuracy, the V10i provides flexible correction options: Internal UHF Radio: For remote sites (5–8 km range) where cellular signals are non-existent. Network RTK (NTRIP): For urban agility, connecting via 4G to existing base station networks for instant corrections. Data Integrity through the Trion Cloud Every coordinate logged is instantly synced to the trion survey cloud. This ensures that your high-precision data is backed up and available for immediate engineering review, preventing the “data silos” that often lead to project rework. Deploying the Precision Revolution The FJD Trion V10i is more than a receiver; it is a gateway to the autonomous site. By combining visual intelligence with 1408-channel reliability, it allows your team to perform at a level of speed and accuracy that was previously impossible. Architect your autonomous future. Contact us today to audit your site requirements and show you, wherever you are, how the FJD Trion RTK ecosystem will bridge your precision and labor gap for 2026.

FJD Trion Series: The GNSS Ecosystem for Every Operational Frontier

In 2026, centimeter-level accuracy is no longer a luxury, it is the prerequisite for the modern industrial site. Whether automating a tractor for row-crop optimization, guiding an excavator on a complex construction project, or deploying autonomous robotic mowers, high-precision geospatial data serves as the invisible backbone of efficiency. However, the modern operational environment is multi-faceted. A remote agricultural field with zero cellular coverage presents entirely different challenges than an urban construction site where skyscrapers block satellite signals. To solve these specific geospatial barriers, the FJD Trion V10 Series provides three distinct, high-performance GNSS RTK receivers: the V10L, the V10i, and the V10a. Three Tools, One Ecosystem (Functions & Differences) To understand the strategic value of the FJD Trion V10 Series, it is essential to look under the hood of each receiver’s specific hardware and communication protocols. While all three share a common mission of high-precision data acquisition, their technical architectures are optimized for different operational frontiers. 1. FJD Trion V10L: The Agile Network Specialist The V10L is the minimalist powerhouse of the lineup, stripped of bulky internal radios to favor a sleek, ultra-portable form factor without compromising on surveying standards. Network-First Architecture: Unlike traditional receivers that require a heavy Base-and-Rover UHF radio setup, the V10L is built primarily as a Network Rover. It leverages an internal high-gain 4G module to connect directly to CORS (Continuously Operating Reference Stations) via the NTRIP protocol. This allows the surveyor to achieve a “Fix” in seconds using only the rover and a handheld controller. Optimal Use Case: City-wide utility mapping, municipal infrastructure audits, and landscape planning in areas where cellular signal is ubiquitous. Technical Differentiator: It is the lightest in the series, reducing operator fatigue during 8-hour field shifts, yet it still tracks GPS (L1/L2/L5) and BeiDou (B1/B2/B3) with the same millimetric sensitivity as its larger siblings. 2. FJD Trion V10i: The Visual Intelligence Powerhouse The V10i represents the pinnacle of “Visual-Inertial-GNSS” fusion, adding a literal eye to the receiver to solve the industry’s oldest problem: “The Blind Spot”. Integrated HD Vision: The base of the V10i houses a high-definition, low-light camera. This is not just for photography; it powers AR (Augmented Reality) stakeout and visual surveying. In the field, the operator can see the target points overlaid on a live video feed on their controller, making staking tasks significantly more intuitive. Measure-from-Distance Capability: The most profound technical advantage of the V10i is its ability to measure points without physical contact. By leveraging Vision-Inertial-GNSS fusion, the software can triangulate coordinates from the camera feed. This means a surveyor can stand 5 meters away from a busy highway lane or a deep construction trench and accurately log a point that would otherwise be dangerous or impossible to reach with a pole. Technical Differentiator: It bridges the gap between GNSS and photogrammetry, maintaining precision even when multi-path interference (signals bouncing off tall glass buildings) would typically cause a standard receiver to lose its “Fix”. 3. FJD Trion V10a: The Heavy-Duty, All-Around Performer The V10a is the “Alpha” tool in the lineup, designed for total autonomy from external infrastructure. Dual-Communication Capability: While it supports Network RTK like the V10L, the V10a features a powerful internal UHF radio (transmitter/receiver). This allows it to act as either a base station or a long-range rover. In environments with zero cellular coverage, such as deep desert oilfields or remote agricultural valleys, the V10a establishes its own 5km to 10km “data link” to provide corrections to other machinery. Interference Resistance: Built into the V10a are advanced anti-jamming and multi-path suppression algorithms. This makes it the standard for “dirty” signal environments like massive construction sites filled with heavy metal machinery and radio interference from other site teams. Technical Differentiator: Its ruggedized shell and high-capacity battery are built for “Frontier Work,” where charging points are rare and the environment is harsh. It is the definitive choice for integrated site backbone roles, providing a stable correction source for FJDynamics autosteer tractors and excavators. The Shared DNA of FJD Trion Reliability While the specialized functions of the V10L, V10i, and V10a provide the “personality” for specific projects, their shared engineering core provides the “reliability” that professional surveyors demand. This shared DNA is built on three technical pillars: IMU-driven tilt compensation, multi-frequency constellation tracking, and deep integration into the FJDynamics autonomous ecosystem. 1. The Math of Speed: Calibration-Free IMU Tilt Compensation One of the most significant bottlenecks in traditional surveying is the “leveling phase,” the seconds spent ensuring the carbon fiber pole is perfectly vertical before a point can be logged. The FJD Trion series eliminates this entirely through a high-grade Inertial Measurement Unit (IMU). Real-Time Vector Calculation: The integrated IMU continuously tracks the receiver’s orientation, pitch, and roll at high refresh rates. It uses complex algorithms to calculate the exact distance between the antenna’s phase center and the tip of the pole, regardless of the angle. 60° Operational Freedom: Field operators can capture accurate, survey-grade points even when the pole is tilted at up to 60°. This is critical when measuring corners of buildings, utility poles, or the edges of deep excavation pits where standing directly over the point is impossible or unsafe. Calibration-Free Readiness: Unlike older generations of tilt-compensated GNSS, the Trion series is “initialization-free”. The IMU stays active and calibrated while the operator walks, allowing for immediate point capture the moment the pole tip touches the ground. 2. Multi-Frequency “Fast Fix” Constellation Tracking In the industrial environments of 2026, signal reliability is the difference between a productive day and an expensive delay. The Trion series features a 1408-channel GNSS board capable of simultaneous tracking across all global navigation constellations. Total Frequency Coverage: The receivers track GPS (L1/L2/L5), GLONASS (G1/G2/G3), BeiDou (B1/B2/B3), Galileo (E1/E5a/E5b), and QZSS (L1/L2/L5). Rapid Cold-Start Performance: By tracking more satellites than standard receivers (typically 30+ visible at any time), the Trion series achieves a “Fix” in under 10 seconds, even in challenging environments like deep urban canyons. Signal Reconstruction Technology: Advanced algorithms work to filter out “multi-path” signals, erroneous

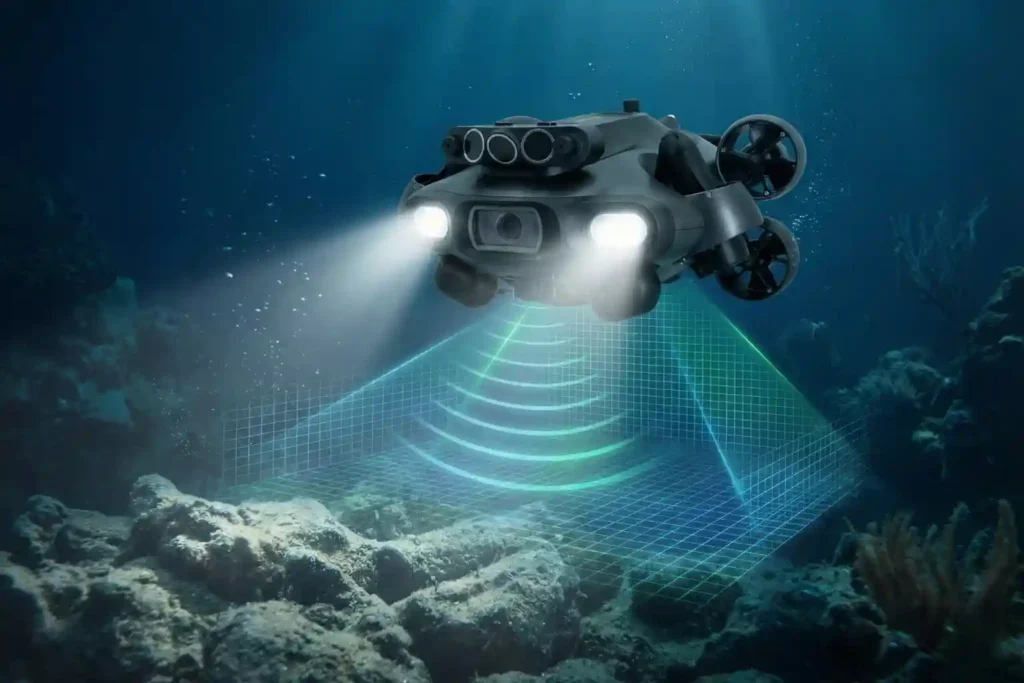

FIFISH E-Master: The Seafloor Mapping Revolution

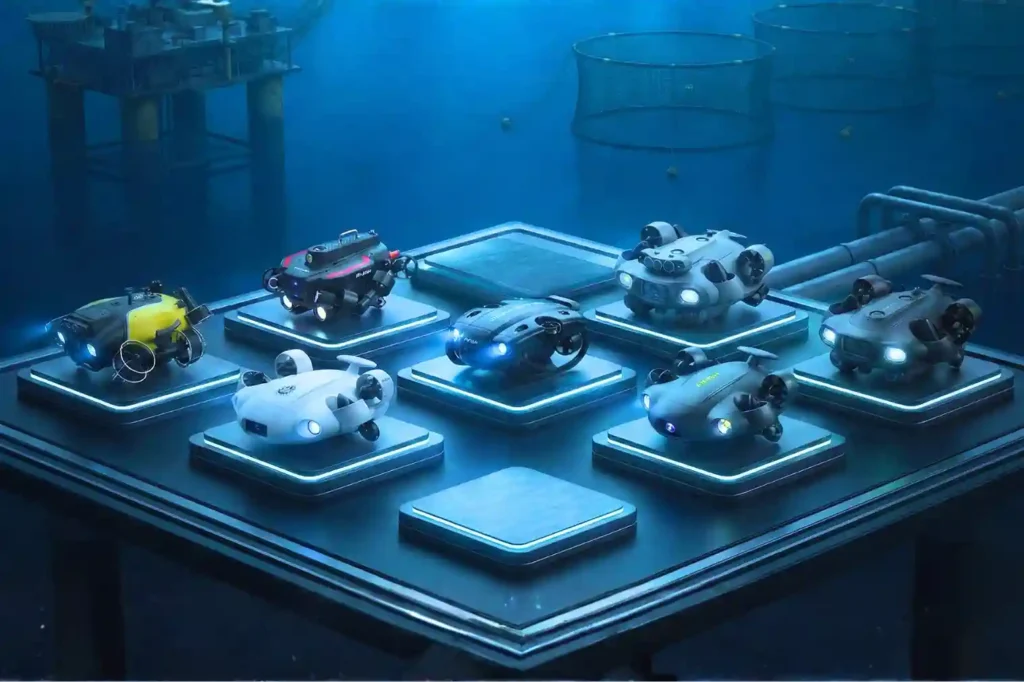

Navigating the Industrial Abyss The Complexity of 2026: Subsea operations have evolved beyond simple visual checks to requiring high-precision data, physical interaction, and deep-water endurance. The Multi-Disciplinary Challenge: No single tool fits all tasks, aquaculture requires agility, while offshore energy demands heavy-duty payloads and millimetric metrology. The Solution: Introducing the QYSEA FIFISH ROV Lineup, an AI-powered fleet designed to provide modular, scalable, and intelligent solutions for every underwater industrial sector. Specialized Tools for Specialized Missions The shift toward autonomous subsea auditing requires more than just a camera on a tether; it requires a specialized workforce of robotic agents. QYSEA’s lineup is engineered to bridge the gap between raw data collection and actionable engineering intelligence. 1. FIFISH V-EVO: The High-Frame-Rate Visual Metrology Standard The FIFISH V-EVO is the premier choice for visual-first inspections where motion clarity and environmental realism are critical. High-Speed Imaging Architecture: The V-EVO features a 4K UHD camera capable of 60 frames per second (fps). This higher frame rate is essential for capturing smooth footage of fast-moving turbine blades, propeller shafts, or moving biological stock in aquaculture, preventing the “motion blur” that plagues standard 30fps ROVs. Adaptive AI Plankton Filtering: One of the primary barriers to underwater clarity is “marine snow” suspended particles and plankton that reflect light and obscure details. The V-EVO utilizes an Adaptive AI filtering algorithm to digitally remove these visual obstructions in real-time, restoring clarity to images even in nutrient-rich or turbid coastal waters. Optics and Illumination: With a 166° ultra-wide field of view (FOV) and 5,000-lumen LED lights (5500K color temperature), the V-EVO maximizes situational awareness, allowing pilots to see structural contexts that narrower lenses miss. AI Vision Station Lock: Using machine vision, the V-EVO can lock onto a specific underwater subject, maintaining its relative position and focus with a single touch, which is critical for long-term observation of slow-growing corrosion or biological samples. 2. FIFISH E-GO: Biomimetic Agility for Industrial Productivity Designed with a “Hammerhead” shark-inspired form factor, the E-GO focuses on hydrodynamic efficiency and rapid operational switching. Ring-Wing Motor Propulsion: The E-GO utilizes a patented ring-wing motor system that provides a 30% power increase over traditional designs. This allows the drone to maintain speeds of 3+ knots even when fighting strong lateral currents common in open-water cage farming. The 9-Second Modular Ecosystem: To minimize site downtime, the E-GO features a quick-release accessory system allowing for tool installation in under 9 seconds. This enables a single ROV to transition from a net-repair mission to a water-quality sampling mission in seconds. Hot-Swappable Dual Power: The E-GO’s dual-battery architecture supports hot-swapping, meaning the ROV can stay powered on and connected to the station while batteries are replaced, enabling continuous “infinite” workflows without restarting missions. Macro Precision: A focused 10cm macro range allows the E-GO to perform extreme close-up inspections of welds, bolts, and delicate marine life that would be out of focus for standard industrial cameras. 3. FIFISH V6 PLUS: The Expert in Millimetric Structural Metrology The V6 PLUS is the enterprise benchmark for non-destructive testing (NDT) and precision measurements. Machine Vision AR Ruler: Moving beyond simple visual estimation, the V6 PLUS features a patented AR Ruler system. By combining machine vision with a laser scaler, it achieves a measurement precision of ±1cm, allowing engineers to accurately measure the length, width, and area of structural defects directly through the FIFISH App. Sonic Distance & Altitude Lock: Dual sonar sensors provide real-time distance and altitude tracking. The “Distance Lock” maintains a fixed stand-off distance from a hull or wall, while “Altitude Lock” maintains a fixed height above the seabed, ensuring the ROV does not drift during delicate NDT scans. Deep-Water Operational Envelope: Rated for 150 meters, the V6 PLUS is built for the deeper inspection requirements of hydropower dams, reservoir gates, and bridge pilings. 4. FIFISH V6 EXPERT: The Multi-Tool Platform for Complex Intervention The V6 EXPERT is the “Swiss Army Knife” of the lineup, designed to carry heavy payloads and diverse sensor arrays. Q-IF Interface Expansion: The V6 EXPERT features a heavy-duty Q-Interface that supports the simultaneous integration of up to 20+ professional tools. These include water samplers (100ml to 1500ml), pH/salinity/turbidity sensors, retrieval hooks, and underwater dozers. Onshore Power Supply System (OPSS): For missions requiring days of continuous monitoring, the V6 EXPERT can be tethered to an onshore power system, removing battery limitations and allowing the drone to stay submerged indefinitely for long-duration infrastructure audits. Enhanced 6000 Lumen Illumination: Dual 3000-lumen headlights provide the ultra-bright lighting necessary for the V6 EXPERT to perform manipulation tasks in the absolute darkness of deep-sea tunnels or silt-heavy environments. 5. FIFISH E-MASTER: The Vessel Hull and Bathymetric Specialist The E-MASTER is a revolutionary industrial AI ROV engineered for hull inspections and seabed mapping. Q-DVL Stabilized Hovering: The E-MASTER integrates both forward and downward Q-DVL (Doppler Velocity Log) modules. This allows for Station Lock Hovering against vertical hulls or moving currents, ensuring the drone remains perfectly steady while measuring biofouling or coating degradation. Integrated Bathymetric Mapping (QY-BT): By fusing data from the Q-DVL and echosounders, the E-MASTER can perform automated 2D and 3D seafloor mapping. Operators can generate topographic maps and calculate reservoir capacities with a single click. AI Measurement Accuracy: Using the QY-MT system, the E-MASTER can analyze underwater objects and fractures with a staggering 99.7% measurement accuracy, providing the high-fidelity data required for class-certified hull inspections. 6. FIFISH X1: The Heavy-Duty Offshore Intervention Powerhouse The X1 is a mission-class ROV designed to handle the most demanding conditions in the offshore energy sector. Heavy Payload and Propulsion: The X1 supports an massive 15kg payload capacity and is powered by the Q-Motor Pro system, which allows it to hold its position and operate in currents up to 4.0 knots. U-INS Plus Inertial Navigation: This system fuses data from the Q-DVL, accelerometers, gyroscopes, and magnetometers to enable precise 3D route planning. The X1 can autonomously navigate complex “jackets” and oil rig structures, following preset paths while the operator focuses on data collection. Tri-Directional Collision Avoidance: To protect the

The QYSEA ROV: Intelligence for the Subsea Era

Navigating the Industrial Abyss The Complexity of 2026: Subsea operations have evolved beyond simple visual checks to requiring high-precision data, physical interaction, and deep-water endurance. The Multi-Disciplinary Challenge: No single tool fits all tasks, aquaculture requires agility, while offshore energy demands heavy-duty payloads and millimetric metrology. The Solution: Introducing the QYSEA FIFISH ROV Lineup, an AI-powered fleet designed to provide modular, scalable, and intelligent solutions for every underwater industrial sector. Specialized Tools for Specialized Missions The shift toward autonomous subsea auditing requires more than just a camera on a tether; it requires a specialized workforce of robotic agents. QYSEA’s lineup is engineered to bridge the gap between raw data collection and actionable engineering intelligence. 1. FIFISH V-EVO: The High-Frame-Rate Visual Metrology Standard The FIFISH V-EVO is the premier choice for visual-first inspections where motion clarity and environmental realism are critical. High-Speed Imaging Architecture: The V-EVO features a 4K UHD camera capable of 60 frames per second (fps). This higher frame rate is essential for capturing smooth footage of fast-moving turbine blades, propeller shafts, or moving biological stock in aquaculture, preventing the “motion blur” that plagues standard 30fps ROVs. Adaptive AI Plankton Filtering: One of the primary barriers to underwater clarity is “marine snow” suspended particles and plankton that reflect light and obscure details. The V-EVO utilizes an Adaptive AI filtering algorithm to digitally remove these visual obstructions in real-time, restoring clarity to images even in nutrient-rich or turbid coastal waters. Optics and Illumination: With a 166° ultra-wide field of view (FOV) and 5,000-lumen LED lights (5500K color temperature), the V-EVO maximizes situational awareness, allowing pilots to see structural contexts that narrower lenses miss. AI Vision Station Lock: Using machine vision, the V-EVO can lock onto a specific underwater subject, maintaining its relative position and focus with a single touch, which is critical for long-term observation of slow-growing corrosion or biological samples. 2. FIFISH E-GO: Biomimetic Agility for Industrial Productivity Designed with a “Hammerhead” shark-inspired form factor, the E-GO focuses on hydrodynamic efficiency and rapid operational switching. Ring-Wing Motor Propulsion: The E-GO utilizes a patented ring-wing motor system that provides a 30% power increase over traditional designs. This allows the drone to maintain speeds of 3+ knots even when fighting strong lateral currents common in open-water cage farming. The 9-Second Modular Ecosystem: To minimize site downtime, the E-GO features a quick-release accessory system allowing for tool installation in under 9 seconds. This enables a single ROV to transition from a net-repair mission to a water-quality sampling mission in seconds. Hot-Swappable Dual Power: The E-GO’s dual-battery architecture supports hot-swapping, meaning the ROV can stay powered on and connected to the station while batteries are replaced, enabling continuous “infinite” workflows without restarting missions. Macro Precision: A focused 10cm macro range allows the E-GO to perform extreme close-up inspections of welds, bolts, and delicate marine life that would be out of focus for standard industrial cameras. 3. FIFISH V6 PLUS: The Expert in Millimetric Structural Metrology The V6 PLUS is the enterprise benchmark for non-destructive testing (NDT) and precision measurements. Machine Vision AR Ruler: Moving beyond simple visual estimation, the V6 PLUS features a patented AR Ruler system. By combining machine vision with a laser scaler, it achieves a measurement precision of ±1cm, allowing engineers to accurately measure the length, width, and area of structural defects directly through the FIFISH App. Sonic Distance & Altitude Lock: Dual sonar sensors provide real-time distance and altitude tracking. The “Distance Lock” maintains a fixed stand-off distance from a hull or wall, while “Altitude Lock” maintains a fixed height above the seabed, ensuring the ROV does not drift during delicate NDT scans. Deep-Water Operational Envelope: Rated for 150 meters, the V6 PLUS is built for the deeper inspection requirements of hydropower dams, reservoir gates, and bridge pilings. 4. FIFISH V6 EXPERT: The Multi-Tool Platform for Complex Intervention The V6 EXPERT is the “Swiss Army Knife” of the lineup, designed to carry heavy payloads and diverse sensor arrays. Q-IF Interface Expansion: The V6 EXPERT features a heavy-duty Q-Interface that supports the simultaneous integration of up to 20+ professional tools. These include water samplers (100ml to 1500ml), pH/salinity/turbidity sensors, retrieval hooks, and underwater dozers. Onshore Power Supply System (OPSS): For missions requiring days of continuous monitoring, the V6 EXPERT can be tethered to an onshore power system, removing battery limitations and allowing the drone to stay submerged indefinitely for long-duration infrastructure audits. Enhanced 6000 Lumen Illumination: Dual 3000-lumen headlights provide the ultra-bright lighting necessary for the V6 EXPERT to perform manipulation tasks in the absolute darkness of deep-sea tunnels or silt-heavy environments. 5. FIFISH E-MASTER: The Vessel Hull and Bathymetric Specialist The E-MASTER is a revolutionary industrial AI ROV engineered for hull inspections and seabed mapping. Q-DVL Stabilized Hovering: The E-MASTER integrates both forward and downward Q-DVL (Doppler Velocity Log) modules. This allows for Station Lock Hovering against vertical hulls or moving currents, ensuring the drone remains perfectly steady while measuring biofouling or coating degradation. Integrated Bathymetric Mapping (QY-BT): By fusing data from the Q-DVL and echosounders, the E-MASTER can perform automated 2D and 3D seafloor mapping. Operators can generate topographic maps and calculate reservoir capacities with a single click. AI Measurement Accuracy: Using the QY-MT system, the E-MASTER can analyze underwater objects and fractures with a staggering 99.7% measurement accuracy, providing the high-fidelity data required for class-certified hull inspections. 6. FIFISH X1: The Heavy-Duty Offshore Intervention Powerhouse The X1 is a mission-class ROV designed to handle the most demanding conditions in the offshore energy sector. Heavy Payload and Propulsion: The X1 supports an massive 15kg payload capacity and is powered by the Q-Motor Pro system, which allows it to hold its position and operate in currents up to 4.0 knots. U-INS Plus Inertial Navigation: This system fuses data from the Q-DVL, accelerometers, gyroscopes, and magnetometers to enable precise 3D route planning. The X1 can autonomously navigate complex “jackets” and oil rig structures, following preset paths while the operator focuses on data collection. Tri-Directional Collision Avoidance: To protect the

Deepwater inspection: Identifying Early-Stage Damage in Offshore Assets with QYSEA

In the offshore energy sector, what you cannot see can cost you millions. Submerged infrastructure from oilfield wellheads to deep-sea port pilings exists in a state of constant chemical and structural attrition. Saltwater corrosion, biofouling, and extreme pressure work in tandem to create micro-cracks and material fatigue that are often invisible to the naked eye. When these early-stage defects are ignored, they inevitably evolve into catastrophic structural failures or environmental disasters. The industry is moving away from basic visual observation toward high-precision, data-driven monitoring. To achieve this, operators require an enterprise-grade platform capable of navigating extreme depths while providing the precision of a laboratory. The QYSEA FIFISH PRO W6 is that platform, an industrial-grade ROV designed to turn subsea data into actionable maintenance intelligence. Technical Superiority of the FIFISH PRO W6 The FIFISH PRO W6 is engineered specifically for harsh deepwater environments where standard ROVs falter. Its technical architecture is built to ensure that “hidden” damage is brought to light with uncompromising clarity. Deepwater Performance: Rated for a 350-meter dive depth, the W6 is a true industrial tool for deep-sea port and oilfield operations. Patented Propulsion: It features a unique 6 Q-motor system that provides stronger power and anti-current stability, ensuring the drone remains steady even in the unpredictable currents of the open ocean. Dual-Camera Visual Intelligence: The W6 utilizes an innovative Dual 4K Camera System. This setup coordinates operation monitoring with motion observation, providing a massive 166° horizontal field of view to ensure operators have a complete picture of the surrounding environment. Advanced Navigation and Stability: Station Lock: This algorithm locks the ROV’s position in place, preventing drift in complicated water environments to allow for exhaustive inspections of a single weld or joint. U-QPS Positioning: The Underwater Quick Positioning System provides real-time ROV location, 3D diving path recording, and point-of-interest (POI) marking, which is essential for mapping recurring corrosion patterns over time. Sonar Array: An optional sonar system enables Distance Lock, Altitude Lock, and Collision Avoidance, allowing the ROV to navigate safely near complex subsea structures in zero-visibility conditions. Precision Tools for Predictive Maintenance Identifying damage is only the first step; quantifying it is what enables predictive maintenance. The FIFISH PRO W6 is a modular “Swiss Army Knife” for non-destructive testing (NDT). Measuring the Invisible: The W6 is equipped with a high-precision ruler combination, including a standard Laser Ruler and an optional AR Ruler. These tools allow engineers to accurately measure the scale of cracks and hull damage to identify and prevent further structural degradation. Modular Versatility: With 5 Q-Interfaces for payload integration, the W6 can be customized with various industrial tools. It can simultaneously carry a robotic arm with a replaceable claw for sample collection and an imaging sonar for dark-water hull inspections. Operational Endurance: Removable Battery: The standard 388Wh battery can be swapped quickly on-site and supports a quick-charging mode that reaches 70% in just one hour. Onshore Power Supply: For missions requiring “unlimited endurance,” the W6 can be tethered to a miniaturized onshore power system, ensuring it can stay submerged as long as the task requires. Securing the Submerged Frontier The FIFISH PRO W6 transforms raw underwater footage into professional work reports. By integrating big data analysis and high-fidelity 3D mapping, it provides offshore managers with a clear roadmap for maintenance, significantly extending the lifecycle of critical assets. Implementing the W6 Workflow: Survey & Record: Use the U-QPS and Dual 4K cameras to create a 3D baseline of your asset. Measure & Analyze: Utilize the Laser/AR rulers to monitor the growth of known micro-cracks during recurring audits. Act & Maintain: Use the Robotic Arm for light maintenance or to clear biofouling for better visual access. Contact us and standardize your deepwater maintenance and turn your most critical offshore asset’s threats of the deep into manageable, actionable insights.

Major Update on GACA Regulation Part 107 Operation of UAS V5

The publication of GACAR Part 107 Version 5 represents a watershed moment for the Kingdom’s aviation sector. This update signifies a transition from a reactive, case-by-case regulatory model to a sophisticated, risk-based regulatory framework. By aligning Saudi Arabia’s General Authority of Civil Aviation (GACA) protocols with international best practices most notably the European Union Aviation Safety Agency (EASA) standards. V5 provides the legal certainty required for massive industrial investment. I. The Core Regulatory Architecture: Risk-Based Categorization The most fundamental change in GACA 107 V5 is the formalization of UAS operations into two primary categories based on the risk they pose to third parties on the ground and other aircraft in the sky: the open category and the specific category. The Open Category (Low Risk): This category is reserved for basic, low-risk operations. It does not require a prior “Operational Authorization” from GACA, provided the pilot adheres to strict standard operating limitations. Subcategory A1 (Fly Over People): Restricted to ultra-light drones typically < 250 g. Pilots must avoid flying over “assemblies of people”. Subcategory A2 (Fly Near People): For drones up to 2 kg or 4 kg (depending on class markings). Requires a high level of pilot competency and a safe distance of at least 30 meters from uninvolved persons. Subcategory A3 (Fly Far from People): For larger drones up to 25 kg. Operations must be conducted at least 150 meters away from residential, commercial, or industrial areas. The Specific Category (Moderate Risk): This is the domain of industrial and commercial drone services. Any operation that falls outside the Open Category, such as flying a 10 kg drone over a populated site or flying beyond visual line of sight (BVLOS) requires a formal Authorization. II. The Technical Mechanics of Standard Scenarios (STS) V5 introduces the GACA standard scenarios (STS), which serve as “pre-defined risk assessments.” Instead of an operator spending months conducting a SORA (Specific Operations Risk Assessment), they can now declare compliance with a specific STS template. GACA STS-V1 (VLOS Populated): This scenario allows for Visual Line of Sight (VLOS) operations at a maximum height of 120 meters (400 ft) over a controlled ground area in populated environments. Technical Drone Requirements: Drones must bear a specific class identification label (C5 or equivalent). This requires a Flight Termination System (FTS), a redundant kill-switch independent of the primary flight controller, and a low-speed mode to mitigate kinetic impact risk. GACA STS-B1 (BVLOS Sparsely Populated): This scenario enables Beyond Visual Line of Sight (BVLOS) operations, a game-changer for long-range asset monitoring. The drone can fly up to 1 km (or 2 km with visual observers) from the pilot. Technical Drone Requirements: Typically requires a C6 class drone. These aircraft must include Direct Remote Identification (Remote ID), which broadcasts the drone’s position, altitude, and serial number in real-time to law enforcement and airspace managers. III. Institutional Requirements: The Three Pillars of Compliance To operate legally under GACA 107 V5, a commercial entity must establish a triad of technical documentation and organizational controls. The Operations Manual (OM): This is the organization’s “geospatial bible.” It must detail the organizational structure, pilot training records, maintenance schedules, and technical specifications for every drone in the fleet. Safety Management System (SMS): GACA now requires a proactive approach to safety. Organizations must implement a system for identifying hazards, analyzing risks, and reporting “near-misses” or incidents back to the GACA UAS department within 72 hours. Emergency Response Plan (ERP): An ERP must be established and “drilled” regularly. It outlines the technical steps to be taken in the event of a link loss (C2 link failure), fly-away, or airspace incursion by a manned aircraft. IV. Remote Pilot Competency and Certification V5 elevates the status of the “Remote Pilot” to that of a certified aviation professional. The certification process is now modular: Fundamental Training: All commercial pilots must pass a GACA-approved theoretical exam covering airspace classification, aviation weather, and radio communication. STS-Specific Accreditation: For advanced missions, pilots must undergo Practical Skill Training and Assessment. This involves demonstrating proficiency in abnormal and emergency maneuvers, such as landing safely after a motor failure conducted by a GACA-recognized training entity. V. Fleet Readiness and Technical Sovereignty Finally, GACA 107 V5 mandates that every UAS used for commercial purposes in the Kingdom be registered and technologically compliant. Digital Registration: Each aircraft must be registered via the GACA portal, receiving a unique nationality and registration mark that must be physically displayed on the airframe. Remote ID Implementation: By the 2026 deadline, all drones operating in the Specific Category must be equipped with remote ID hardware. This creates a “digital license plate” for every drone, ensuring accountability and facilitating the future of a high-traffic low-altitude economy. The transition from Version 4 to GACAR Part 107 Version 5 introduces a structured methodology for operational authorization through Standard Scenarios (STS). These scenarios are technically defined “safety envelopes” that allow operators to bypass the complex Specific Operations Risk Assessment (SORA) process by adhering to a set of pre-verified technical and operational mitigations. For industrial players, this means the difference between a three-month approval cycle and a near-instantaneous operational declaration. Understanding the Standard Scenarios (STS) I. GACA STS-01: Precision VLOS in Populated Zones GACA STS-01 is the primary regulatory pathway for urban and high-density industrial work. It allows for operations within Visual Line of Sight (VLOS) at altitudes up to 120 meters (400 ft) over controlled ground areas. Technical Hardware Requirements (C5 Class Equivalence): To be compliant with STS-01, a UAS must meet rigorous hardware safety standards: Flight Termination System (FTS): The aircraft must be equipped with a redundant, independent “kill-switch.” This system must be capable of terminating flight either by cutting power to the motors or deploying a parachute even if the primary flight controller or C2 (Command and Control) link fails. Low-Speed Mode: When operating in proximity to people (within the controlled area), the drone must have a selectable low-speed mode that limits the maximum horizontal velocity (typically to 5 m/s) to minimize kinetic energy in the event of an

Cloud-First Mapping: Accelerating Construction Timelines with ArcGIS Online and ArcGIS Enterprise

Every drone mission, whether it is an inspection of a solar farm in NEOM or a volumetric survey in the Empty Quarter ends with a massive influx of data. Thousands of images, high-density point clouds, and thermal layers require a “home.” Without a robust platform to organize and visualize this information, your drone program is just a collection of hard drives. In the world of professional GIS, the choice of a home usually comes down to two paths: ArcGIS Online and ArcGIS Enterprise. Both platforms are industry-leading, but they offer fundamentally different approaches to how you manage, secure, and share your spatial intelligence. Choosing the wrong one can lead to operational bottlenecks or security risks. ArcGIS Online vs ArcGIS Enterprise Technically, both platforms allow you to create maps, analyze data, and share insights. However, the “where” and “how” differ significantly. ArcGIS Online: ArcGIS Online is a cloud-based Software-as-a-Service (SaaS) platform. Esri hosts the software, manages the updates, and handles the infrastructure. Zero Infrastructure: You don’t need servers or a specialized IT team to launch. You simply log in via a browser. Rapid Scalability: If you suddenly add 50 new field users, the cloud scales instantly to accommodate them. Mobile Synergy: It is perfectly optimized for field apps like ArcGIS Field Maps, allowing drone pilots to upload data directly to a shared cloud map. ArcGIS Enterprise: ArcGIS Enterprise is the full-featured GIS system designed to run on your infrastructure whether that is on-premises servers or your private cloud (like AWS or Azure). Total Data Sovereignty: You control exactly where your data sits. This is vital for industries with strict national security or privacy regulations. Advanced Analytics: Enterprise includes powerful components like the ArcGIS Image Server, which handles the massive raster processing required for large-scale drone orthomosaics. The Four Components: It consists of a Web Adaptor, a Portal, a Server, and a Data Store, giving your IT department granular control over every connection and permission. Choosing the Right Stack for Industrial Excellence The decision is rarely about which software is “better,” but rather which one fits your industry’s regulatory landscape. In Saudi Arabia, where giga-projects and the energy sector are governed by strict data residency laws, ArcGIS Enterprise is often the gold standard. It allows organizations to keep sensitive infrastructure data behind their own firewalls while still providing a collaborative “Portal” for engineers to access drone-captured Digital Twins. Conversely, for rapid urban development and environmental monitoring, ArcGIS Online offers a lower barrier to entry. It allows project managers to share interactive maps with stakeholders globally without the complexity of managing server hardware. Build Your Geospatial Future The future of industrial intelligence is not just about flying drones; it is about building the infrastructure that lives on the ground. Whether you need the agile, cloud-native power of ArcGIS Online or the secure, robust environment of ArcGIS Enterprise, the right architecture is essential for long-term success. As a strategic geospatial partner, we specialize in helping organizations choose and implement the right Esri stack. We bridge the gap between drone data acquisition and long-term GIS management. Let us help you architect a GIS solution that turns your drone data into a national asset.

Integrating Real-Time Data Acquisition and GIS Processing in Industrial Intelligence

In the traditional era of drone mapping, the capture of aerial imagery was only half the battle. For years, the bottleneck was the processing, loading thousands of high-resolution images onto local workstations that would churn for days to produce a single orthomosaic. This fragmented approach led to data silos, inconsistent results, and a lack of real-time collaboration. Today, we are witnessing a paradigm shift. Site Scan for ArcGIS, a cornerstone of the ArcGIS Reality suite, has transformed drone mapping into a seamless, end-to-end cloud-based workflow. By leveraging the unlimited scalability of the cloud, organizations can now handle massive datasets that were previously impossible to process locally. This is not just a change in software; it is an evolution of how we perceive and manage physical reality. From automated flight planning in the field to advanced AI analytics in the boardroom, the cloud is the engine driving the next generation of industrial intelligence. Autonomous Field Operations Technical excellence in drone mapping is not a product of chance; it is a meticulously engineered outcome that begins long before the drone ever leaves the ground. Within the site scan for ArcGIS cloud-based operations ecosystem, the ArcGIS Flight app serves as the sophisticated “tactical interface.” It shifts the paradigm from manual, pilot-dependent flight to a software-defined, repeatable mission architecture that ensures absolute data fidelity. I. Advanced 3D Mission Architectures and Photogrammetric Geometry Modern industrial assets, ranging from sprawling refinery complexes to complex bridge structures require more than a standard 2D “lawnmower” grid. To build a true Digital Twin, the system must capture the “verticality” and occlusion zones of an asset. Perimeter and Crosshatch Missions: For assets with significant vertical relief, such as telecommunications towers or high-rise construction sites, the system utilizes “Perimeter Scans.” The drone executes a series of concentric orbits at multiple altitudes, with the gimbal automatically adjusting its pitch to maintain a consistent angle toward the center. This ensures that every vertical face is captured with high overlap, typically maintained at 80% sidelap and 80% frontlap, providing the dense point cloud required for sharp, un-warped 3D meshes. Corridor Mapping and Vertical Inspection: For linear assets like pipelines or highways, the flight app utilizes corridor-specific algorithms that optimize the flight path to minimize battery consumption while maximizing coverage. In vertical inspection modes, the drone maintains a precise, fixed “stand-off” distance from a vertical face (like a dam wall or pylon), capturing high-resolution “flat” imagery that can be processed into specialized vertical orthomosaics. II. Intelligent Terrain Following and GSD Consistency One of the most critical variables in photogrammetry is the Ground Sample Distance (GSD), the physical distance on the ground represented by a single pixel. If a drone flies at a constant altitude above sea level while the terrain rises and falls, the GSD varies, leading to inconsistent resolution and measurement errors. Dynamic Altitude Adjustment via DEM Integration: ArcGIS Flight integrates high-resolution digital elevation models (DEMs). The drone dynamically adjusts its altitude in real-time to maintain a constant height above the ground surface. This results in a uniform GSD across the entire dataset, ensuring that a measurement taken on a mountain peak is as accurate as one taken in a valley. Automatic Overlap Recalculation: The software monitors ground speed and wind resistance in real-time. If the drone encounters a strong headwind, the system recalibrates the shutter trigger intervals. This ensures the required overlap is maintained perfectly, preventing “gaps” in the data that could lead to failures during the cloud-processing phase. III. Sensor Integration and Field-Level Georeferencing The accuracy of the final map is only as good as the metadata attached to each image. Site Scan supports advanced hardware integration to eliminate the need for traditional, time-consuming ground surveys. RTK and PPK Workflows: The flight app natively communicates with Real-Time Kinematic (RTK) and Post-Processed Kinematic (PPK) enabled drones. By receiving corrections from a base station or NTRIP network, the drone geotags each image with centimeter-level accuracy at the moment of capture. This minimizes, and often eliminates, the need for laying manual Ground Control Points (GCPs), saving hours of field labor. Multi-Sensor Support: Beyond standard visual (RGB) sensors, the framework supports multispectral and thermal payloads. This allows for the capture of specialized data layers. such as vegetation health indexes or thermal signatures for solar farm inspections. All managed within the same autonomous flight interface. IV. Pre-Flight Rigor and Field-to-Cloud Synchronization Custom Safety Checklists: To ensure enterprise-wide compliance, administrators can push mandatory pre-flight checklists to the field app. Pilots must verify everything from airspace authorization (LAANC) to battery voltage and signal strength before the “Take Off” button is enabled. Quick Tiling for Field Verification: One of the most powerful features of the cloud-based operation is Quick Tiling. Immediately after landing, the pilot can generate a low-resolution orthomosaic preview in the cloud while still on-site. This allows for instant verification: Did we cover the entire site? Are there any blurry images due to low light? If a gap is detected, the pilot can re-fly the specific segment immediately, preventing a costly return trip to a remote site. Transforming Pixels into Insight The true technical “engine” of site scan for ArcGIS cloud-based operations lies in its processing architecture. By decoupling data computation from physical hardware, Site Scan leverages the elastic power of the cloud to perform complex photogrammetric reconstructions that would overwhelm even the most advanced local workstations. This section explores the mechanics of how raw aerial imagery is transformed into a high-fidelity geospatial intelligence product. I. Elastic Computing and Massive Parallelization Traditional photogrammetry is a computationally “heavy” task that requires intense CPU and GPU resources. In a local environment, this creates a linear bottleneck: the more images you have, the longer you wait. Site Scan solves this through massive parallelization. Distributed Task Processing: When a dataset is uploaded to the Site Scan Manager, the cloud architecture breaks the project into thousands of discrete tasks. These tasks are distributed across an elastic cluster of server nodes. For instance, while one node calculates the internal orientation of a camera,