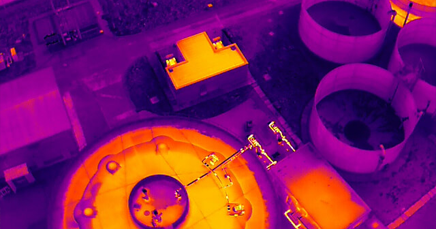

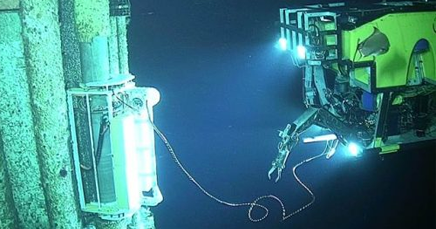

Inspection

Terra Drone Arabia provides comprehensive aerial and underwater inspection services that drastically reduce downtime, improve safety, and deliver high-resolution actionable insights — all without scaffolding, shutdowns, or confined-space entry.