Autonomous Maintenance: How the low altitude economy Will Inspect NEOM’s The Line in 2026

The Density Challenge When we talk about NEOM’s The Line, we are not discussing a standard skyscraper. We are talking about a continuous, 170km-long structure where structure and facilities are bound together in a straight, vertical line. Unlike traditional cities where utilities are spread out horizontally, The Line compresses everything from energy, water, transport, and structural beams into a tight, stacked footprint. This creates a unique maintenance nightmare: overlapped utilities and narrow, vertical corners that are impossible for humans to access safely. In this dense environment, a single pipe failure can cascade into critical electrical systems because they are “gathered” so closely together. Traditional maintenance methods like hanging platforms are too bulky and slow for these confined, high-tech corridors. The solution is not “more people.” It is a new layer of infrastructure. This is the low altitude economy, a dedicated digitized airspace where specialized autonomous robots navigate the tight gaps and vertical shafts to inspect, clean, and maintain the city without human intervention. The Invisible Maintenance Layer In 2026, the maintenance system of The Line will operate as a “Drone Hive,” seamlessly integrated into the building’s spine to handle the complex, gathered infrastructure. I. The Drone Hive (Advanced Docking Stations) Imagine a network of autonomous stations, such as the next-generation DJI Dock 3 (conceptually evolving from the current Dock 2), embedded directly into the utility layers of the megastructure. These compact, weather-proof stations act as home bases. At night or during low-traffic hours, drones automatically deploy to scan the narrow vertical shafts, creating a persistent cycle of monitoring that no human crew could match. II. Navigating the Narrow Corners The Line’s design creates deep, narrow recesses where utilities overlap. Standard drones cannot fly safely in these confined, GPS-denied zones. The solution is the Voliro T. Omnidirectional Flight: Unlike standard drones, the Voliro T uses tiltable rotors to fly in any orientation. It can hover sideways or upside down to navigate the tight corners between a water pipe and a structural beam. Contact Inspection: It can press a probe against a pipe buried deep in a vertical shaft to test for corrosion or sealant failure, ensuring integrity even in the most crowded utility zones. From Inspection to Intelligence The true power of this system isn’t just flight; it’s the ability to untangle the complexity of bound facilities. We are moving from simple inspection to predictive maintenance. III. Predictive Maintenance In a structure where facilities are gathered so tightly, you cannot wait for a leak to happen. The system uses predictive maintenance to analyze the “overlapped” layers of the building. Thermal Scanning: Drones fly the vertical corridors, using thermal sensors to “see” through the layers. They can detect a cooling leak behind a wall panel or an overheating cable tray hidden by a structural beam. The Digital Twin: Every byte of data feeds into NEOM’s Digital Twin. Because the structure and facilities are bound together, the Twin can predict how a vibration in the rail line might affect the plumbing stack next to it. It logs defects, identifies the exact replacement part for that specific narrow corner, and schedules the repair before a failure occurs. IV. Safety & Aesthetics By eliminating bulky external cranes, we preserve the sleek aesthetic of The Line. More importantly, using drones for these narrow, vertical corners removes the risk of sending personnel into confined, high-altitude utility shafts. It turns a high-risk job into a supervised digital workflow. Proving the Concept Today The technology to maintain the vertical cities of the future exists today. It just needs to be scaled. The low altitude economy is not science fiction; it is the operational standard for 2026. You can deploy these autonomous workflows on your current high-rise assets right now to reduce costs and risk and get a FREE 3-month progress monitoring period through talking to our expert.

Precise Prediction: Low Altitude Economy Aerial Data for Digital Twin Infrastructure.

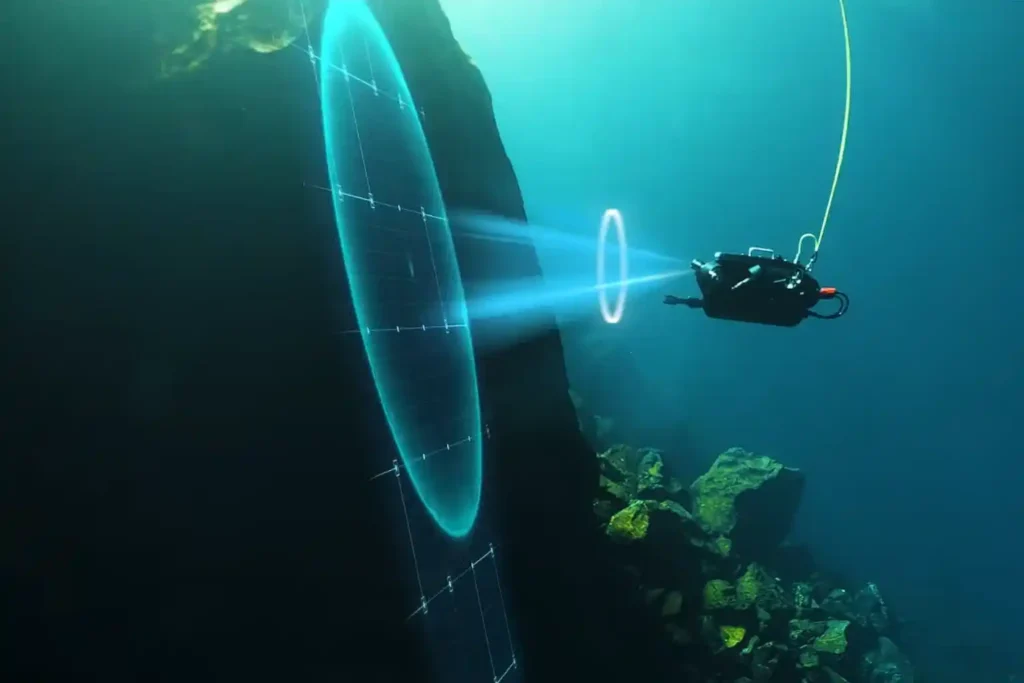

The Urban Data Gap Smart cities like NEOM or Riyadh are not just collections of concrete and glass. They are complex, living systems that breathe, move, and consume energy. Managing such complexity requires real-time intelligence. Yet, many city planners still rely on static ground surveys and outdated maps. They cannot see how a new skyscraper might block airflow or how a road expansion will truly affect traffic until construction is finished. This data gap creates a blind spot that leads to costly errors. The solution lies in the sky. The low altitude economy, the active layer of airspace below 1,000 feet offers a continuous stream of high-resolution aerial data. This data is the fuel that builds the essential digital twin infrastructure for modern urban management. By moving from static maps to dynamic aerial insights, we can predict the future of our cities before we pour the first cubic meter of concrete. Capturing the City in High-Definition To manage a smart city, you must first measure it. Drones act as the sensory layer of the modern metropolis, capturing the physical world in minute detail. I. The Aerial Sensor Network We deploy drones equipped with advanced remote sensing toolkits. These are not just cameras; they are sophisticated instruments. LiDAR sensors shoot laser pulses to measure the exact height of buildings and trees. Thermal cameras detect heat leaks in pipelines and buildings. Multispectral sensors analyze the health of urban green spaces. This network captures the physical city with a level of detail that ground crews simply cannot match. II. 3D City Modeling and Integration This raw data is transformed into precise 3D models. We map every street corner, utility pole, and building facade. This creates the accurate geometric base of your digital twin infrastructure. But data alone is not enough. It must be organized. We build high-resolution maps and GIS databases to store this influx of information. The critical step is integration: ensuring data flows seamlessly from the drone to the database. This creates a “living” map that updates constantly, rather than a static snapshot that expires in a month. Simulating the Future When you have a living digital model, you gain the power of simulation. This is where data turns into decision-making power for city leaders. III. Urban Simulation and Planning Digital twin infrastructure allows planners to test ideas in a virtual world. You can simulate traffic flow during rush hour to test a new intersection design. You can model wind patterns to see how a new tower will affect pedestrian comfort. You can even simulate energy usage across a district to optimize the power grid. This predictive capability removes the guesswork from urban planning. IV. Environmental and Project Management The benefits extend to the environment. Drones monitor air quality sensors and detect urban “heat islands” areas that become dangerously hot. This data helps planners design cooler, healthier parks and living spaces. For the massive giga-projects driving Vision 2030, speed is everything. Aerial surveys track construction progress day by day. Project managers can overlay the digital plan onto the real-world progress to catch errors early. This keeps projects on schedule and saves millions in rework costs. Building the Digital Foundation The transition to a smart city requires a consistent, reliable data pipeline. The low altitude economy provides the speed and cost-efficiency needed to maintain a live digital twin infrastructure. It turns the sky into a digital asset that serves the city on the ground. Don’t plan your city on outdated maps. Partner with Terra Drone Arabia to build your digital foundation. We invite urban developers and government entities to claim a FREE 3-month progress monitoring period on a key development site. Experience the power of live aerial intelligence and start building your future today.

Economy under 1,000 Feet: The Rise of LAE in Smart Cities

The Next Industrial Airspace Layer We often look at the sky and see empty space. However, a quiet revolution is happening just above our heads. This is the rise of the low altitude economy (LAE). This term refers to a new economic and operational domain occupying the airspace below 1,000 feet. It represents the next frontier for industrial efficiency. Global industries are moving fast. They are digitizing their airspace and adopting unmanned systems to perform autonomous inspections. This shift is not just a global trend; it is a critical component of Saudi Arabia’s Vision 2030. The Kingdom is building smart cities and transforming its industrial base. These massive projects require accurate, safe, and continuous aerial operations. Traditional ground methods cannot support this scale. The low altitude economy and industrial applications provide the only viable solution to manage these large-scale assets efficiently. Core Technologies Enabling the LAE To make this new economy work, we need a robust technological foundation. The LAE relies on a stack of advanced systems that ensure safety and predictability. I. The Technological Stack for Safe Operations Unmanned Traffic Management (UTM): We cannot have drones flying blindly. UTM acts like air traffic control for drones. It coordinates airspace, ensures compliance, and prevents collisions. BVLOS Frameworks: Real value comes when drones fly Beyond Visual Line of Sight (BVLOS). This framework establishes safe corridors for drones to operate over long distances, such as along pipelines, utility grids, and coastal zones. Autonomous Drone Stations: Efficiency demands persistence. Autonomous docking stations allow drones to land, charge, and deploy 24/7 without a human pilot on site. Remote Sensing Toolkit: The drone is just the carrier. The value lies in the sensors. We use LiDAR for depth, thermal imaging for heat detection, multispectral sensors for vegetation analysis, and methane detectors for gas leaks. Geospatial Data Infrastructure: All this data must go somewhere. We build high-resolution maps and GIS databases. These form the basis of digital twins, allowing operators to manage physical assets in a digital space. These systems interact seamlessly. They create a predictable and scalable workflow that transforms low altitude economy and industrial applications from a concept into a daily operational reality. Transforming Critical Sectors The application of this technology transforms how we manage the three pillars of modern society: Energy, Utilities, and Urban Development. II. Energy Sector Applications The energy sector demands the highest level of safety and monitoring. Pipeline Integrity: Drones monitor the Right-of-Way (ROW) along vast pipeline networks. They detect leaks and security breaches instantly, protecting the environment and the asset. Flare and Tank Inspection: We replace dangerous manual climbing with drone inspections. Drones perform visual, thermal, and Ultrasonic Thickness (UT) checks on flare stacks and storage tanks. This assesses corrosion and wall health without shutting down operations. Sustainability: Specialized sensors quantify methane and Greenhouse Gas (GHG) emissions. This data helps energy companies meet strict regulatory compliance and sustainability goals. III. Utilities and Power Infrastructure Grid reliability is non-negotiable. Drones ensure the lights stay on. Powerline Inspection: Drones capture high-resolution visual and thermal images of powerlines. LiDAR sensors measure the sag of the lines with centimeter precision. Vegetation Management: Overgrown trees cause outages. Drones analyze vegetation encroachment, allowing utility companies to trim trees only where necessary. Renewable Assets: As the Kingdom adopts green energy, drones inspect solar PV panels for dead cells and wind turbines for blade damage, ensuring maximum energy output. IV. Urban Development and Smart Cities Smart cities like NEOM require smart construction data. Digital Twins: Drones capture data to build 3D city models. These Digital Twins allow planners to simulate traffic, weather, and energy usage before building anything. Progress Tracking: Megaprojects move fast. Aerial surveys track construction progress day by day. This helps project managers catch errors early and keep the project on schedule. Environmental Monitoring: Sensors on drones monitor air quality and heat islands in urban areas. This data helps city planners design cooler, healthier living spaces. Accelerating Efficiency and Adoption The shift to the low altitude economy and industrial applications is not just about technology; it is about business results. V. Why LAE Accelerates Efficiency Cost and Frequency: Automated drones inspect assets more frequently at a lower cost. You can inspect a site daily instead of monthly. Human Safety: We remove humans from high-risk environments. No more climbing towers or entering confined tanks. Real-Time Data: Reports arrive in near real-time. This integration with enterprise systems allows for faster decision-making. National Scale: This technology supports cross-sector interoperability. Data collected for a road project can also help utility companies, supporting national-scale digital initiatives. VI. Pathway to Adoption Governments and industry operators must act now to build this ecosystem. Establish Readiness: Organizations must prepare their technical systems for BVLOS and UTM-aligned operations. Deploy Autonomy: Install autonomous drone stations to enable routine, high-frequency missions. Centralize Data: Build repositories to unify survey and inspection data. Start Pilots: Conduct pilot programs with measurable KPIs to prove the value. Ready to transform your low altitude economy energy, utility, or urban development projects? Let’s realize it through advanced sensing, processing, and data management platforms.

Quadruped Ground Robot with Zero Human Risk For Hazardous Industrial Inspections.

The Unsolved Risk in Industrial Ground Inspection Industrial facilities, power plants, pipeline corridors, deep tunnels, and vast construction sites demand continuous oversight. This oversight traditionally falls to human patrol inspectors. These workers face constant, severe hazards: exposure to toxic gases, extreme heat, high voltage, complex obstacles, and unstable terrain. This manual ground patrol method creates two major problems: High Risk: It constantly puts personnel in harm’s way, leading to potential injuries and high operational safety costs. Low Efficiency: Patrols are repetitive, slow, and often yield subjective data. The need for constant human supervision reduces efficiency and increases labor costs. Modern industry requires a solution that is tireless, fearless, and precise. The necessary transformation is intelligent, unmanned inspection using specialized ground robots. This powerful shift to ground robotics for inspection eliminates human exposure while ensuring that critical assets are monitored $24/7$. Core Technical Capabilities and Industrial Application The solution to the ground risk problem is the agile autonomy and rugged design of the Deep Robotics X30 quadruped robot. This machine is built specifically to operate where humans cannot, turning hazardous patrol routes into repeatable, digital missions. I. Core Technical Advantage: All-Terrain Autonomy The X30 platform’s mechanical and digital architecture guarantees performance and reliability in the MENA region’s challenging industrial environments. A. All-Weather, All-Terrains Coverage The X30’s physical design overcomes almost any obstacle. Extreme Protection: The robot boasts industrial protection above IP66, making it waterproof and dustproof. This allows it to operate continuously for 24 hours in severe operating environments such as heavy rain, snow, or hail. Superior Mobility: It achieves superior mobility by easily navigating obstacles and unstructured surfaces. It can climb stairs up to a 45° slope, stably climb hollow industrial stairs, and move freely through complex environments like ruins, gravel, stone mills, and rough grasslands. This capability minimizes disturbance to the scene and reduces the chance of secondary accidents. Adaptation: The robot exhibits strong adaptation capability, achieving rapid deployment for high-precision data acquisition, analysis, and danger warning. B. Smart Digital Transformation and Control The X30 is fundamentally a digital asset, designed to integrate seamlessly into a centralized control environment. Closed-Loop Workflow: The navigation system handles complex business processes. The Smart Controller simultaneously processes navigation and business-related programs, primarily providing map construction and location navigation. This system enables a closed-loop workflow: High-precision auto-navigation, auto-charge, automatic data capture, and real-time data upload to the superior site. Risk Detection: The entire process connects to the centralized control system. Real-time data syncs immediately, allowing the system to detect potential defects in time to prevent incidents, ensuring the safe operation of equipment. II. Application Deep Dive: Power & Utilities (P&U) and Tunnels The X30 directly supports the transformation of routine asset monitoring within critical infrastructure. A. Autonomous Inspection Workflow for P&U The X30 facilitates efficient, digital, intelligent inspection with a simple autonomous workflow: Path Planning: Operators explore targets and set up the inspection path and mission. Execution: The robot performs real-time inspection based on pre-set navigation paths. Reporting and Charge: It generates real-time results and reports, and then returns for auto-charge, preparing for the next inspection cycle. Advanced Sensing: The robot uses a Bi-spectrum Camera (infrared/visible light) for intelligent recognition and defect alarm analysis. It also features an Acoustic Imager to achieve precise sound source positioning, helping to accurately distinguish and quickly troubleshoot different types of partial discharge (like corona or floating discharge). Remote Action: Equipped with an Agile Robotic Arm, the X30 can execute remote tasks such as grabbing, switching doors, or picking up items, enabling unmanned operation and maintenance. B. High-Accuracy Inspection in Tunnels and Mining The X30 excels in linear, complex, and hazardous underground environments, replacing human patrol inspectors. Tunnels and Underground Cable Corridors: The X30 is capable of fully unmanned autonomous inspection in complex terrains of underground cable tunnels. It prevents manned errors in traditional inspection, improving monitoring efficiency and reducing risk from high-temperature or toxic environments. Metal & Mining: The robot patrols complex environments such as narrow pipes, heavy dust areas, and muddy roads. This capability greatly reduces the exposure of patrol inspectors to potential hazards, improving efficiency and preventing equipment failures ahead of time. High-Risk Specializations and Value The value of the X30 is maximized when it is deployed to situations of extreme risk, where its robust safety features save lives and minimize financial loss. III. Application Deep Dive: Rescue Operations and Construction The X30’s ability to operate in severely compromised environments makes it an ideal robotic partner for emergency services and quality assurance. A. Smart Rescue Workflow The X30 is designed to replace rescue personnel in high-risk environments for search and rescue work. Hazard Detection: The robot ventures into the post-disaster area, captures images, and transmits them back. It identifies hazardous gases using integrated Gas Sensors (detecting carbon monoxide, hydrogen sulfide, etc.) and collects temperature data via thermal imaging. It then devises the safest evacuation route. Communication and Support: The robot can collect sounds from trapped individuals using the Pickup feature and establish essential communication with them. It also has load operation capabilities, enabling it to carry supplies or equipment to the disaster site. Resilience: Its all-weather, all-terrains coverage allows it to traverse $20 \text{ cm}$ obstacles and $30^\circ$ slopes on ruins and rubble, minimizing disturbance to the scene and reducing the chance of secondary accidents. B. Construction and Factory Inspection The X30’s precise mobility and sensing capabilities translate into significant efficiency gains in construction and manufacturing settings. Construction Mapping: The robot assists with auxiliary surveying and mapping in complex environments. Combining its excellent obstacle avoidance function with a 3D Survey Scanner, it automatically performs tasks such as on-site scanning, surveying, and project progress monitoring along a preset path. Factory Patrol: The X30 ensures $24/7$ continuous inspection in hazardous, high-temperature, or high-pressure manufacturing environments. It monitors temperature, pressure, and humidity variables with high-precision inspection modules, detecting problems that manual inspections often miss and reducing personnel safety threats. Risk Reduction: In construction areas and metal/mining environments, it surveys, keeping workers out of severe working conditions and narrow

Integrated Aerial, Terrestrial, and Marine Inspection Framework for Industrial Asset Integrity

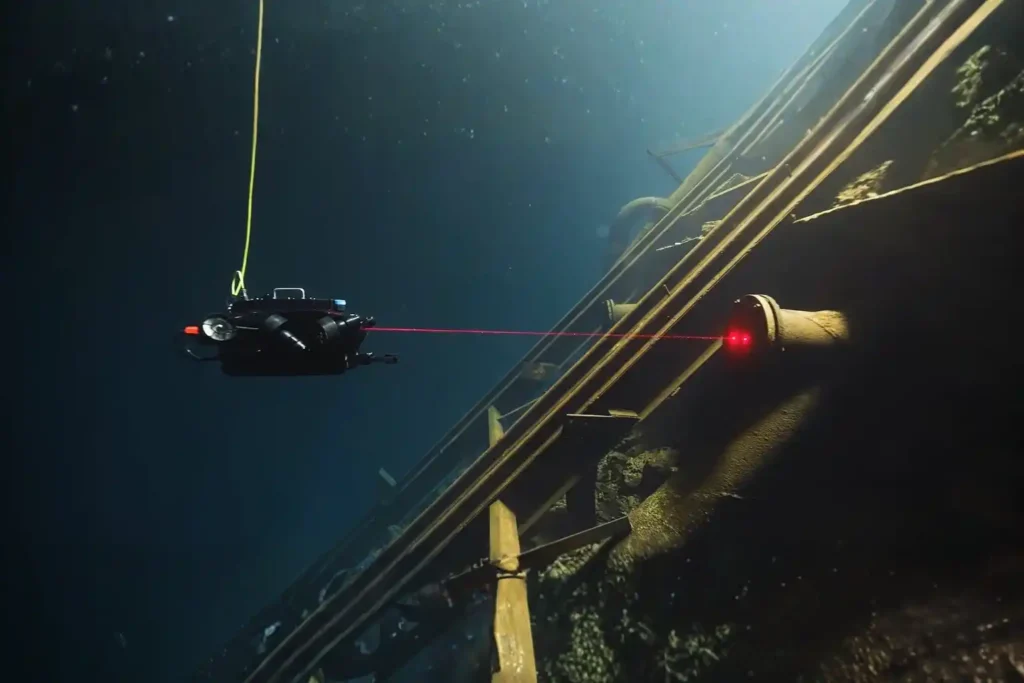

The Three-Dimensional Integrity Challenge Managing major infrastructure from long-distance pipelines and highways to offshore oil facilities, is a massive task. Asset owners in the MENA region face the immense challenge of maintaining structural health across all three major environments: air (high-altitude assets), land (linear corridors), and sea (submerged foundations). The traditional approach to managing these assets is severely flawed. Manual surveys on land, reliance on dangerous scaffolding or rope access in the air, and sending human divers into dark, high-risk waters (Sea) are slow, dangerous, and create fragmented data. This leaves asset owners vulnerable to unexpected failure and huge repair costs. Modern asset management demands a unified solution. It requires a specialized, robotic approach capable of performing objective, centimeter-accurate inspections in every domain. This necessary shift leads to the core of our strategy: full-spectrum asset inspection, utilizing specialized robotics and sensors to create one unified source of truth for the entire asset portfolio. The Land and Air Domains The beginning of the full-spectrum approach focuses on digitizing the vast surfaces of land and the complex vertical structures above ground. I. Land Inspection: Mapping the Foundation and Corridor Land assets including highways, pipelines, and industrial facilities, suffer from time delays and difficult access points during inspections and surveys. We overcome these challenges through integrated geospatial and robotic solutions. LiDAR and Photogrammetry: We use integrated aerial LiDAR systems to create the accurate Digital Terrain Model (DTM) needed for precise road and pipeline routing. Photogrammetry then provides the necessary high-resolution visual context. This initial Topographic Mapping is crucial for checking and verifying design against reality before construction proceeds. External Land Inspection: For inspecting rough terrain, checking pipeline integrity, or navigating hazardous ground areas beneath equipment (under-skids), we deploy advanced Deep Robotics platforms. These specialized ground robots access dangerous environments that are too unstable or confined for human inspectors, performing detailed visual and non-contact checks on assets. Internal Land Access (Confined Space): Even internal land structures like large ducts, vessels, or complex pipes require checks. For these challenging spaces where GPS signals fail, we use the Terra Xross 1 drone. This protected, cage-equipped drone flies safely inside these vessels, collecting high-resolution visual data to check for corrosion and structural issues, eliminating the need for human entry into hazardous atmospheres. Application: This combined data flow is used for rapid Topographic Mapping, volumetric analysis (earthwork optimization), and early design validation through BIM Integration. II. Aerial Inspection: Vertical Structures and Confined Spaces Vertical industrial structures from flare stacks and high piping to storage tanks present significant height risks. Our aerial inspection minimizes human exposure while delivering precise Non-Destructive Testing (NDT). Vertical NDT (Contact Inspection): For vital contact-based measurements, we deploy the Voliro T drone. This specialized aerial robot performs external, contact-based UT (Ultrasonic Thickness) Inspection and thermal scanning on challenging vertical and overhead assets, like tank walls and high piping. The Voliro T applies the stable force required to take precise thickness readings, verifying material integrity. High-Altitude Visual: We use standard industrial drones to perform rapid, high-resolution visual inspection of tall structures, roofs, and large-area piping, quickly identifying general wear or coating failure. Internal Safety (Confined Space): In large industrial vessels and tanks, the Terra Xross 1 drone ensures internal visual checks are performed safely and efficiently, further reducing personnel risk in hazardous, enclosed environments. The Sea and Synthesis Domains The third dimension of inspection, the marine environment is the most challenging. Successfully integrating this data creates the core of the predictive strategy. III. Sea Inspection: Qysea W6 NAVI for Coastal Resilience The safety risks, limited visibility, and time constraints of human divers make robotic inspection non-negotiable for subsea assets. Problem Solved: Our solution eliminates diver risk, time constraints, and low data quality in subsea environments. The Technology (W6 NAVI): We utilize the Qysea Maritime ROV W6 NAVI as the precision platform for underwater inspection. This compact, robust ROV is designed for stability and advanced data acquisition in open sea and port environments. Key Capabilities (W6 NAVI): The W6 NAVI provides several vital functions: Precision Navigation: It achieves enhanced hovering stability even in high currents, which is essential for accurate data collection near structures. Robust Surveys: It supports continuous, automated survey paths for consistent, repeatable data acquisition. Sonar and Payloads: It utilizes specialized scanning sonar to navigate in zero visibility conditions and carries modular payloads, including those necessary for subsea NDT and structural measurement. Application: The W6 NAVI is critical for inspecting subsea pipelines, performing scour assessment (foundation erosion) around jetties, and checking hull integrity. IV. The Predictive Synthesis: The Full-Spectrum Digital Twin The strategic value of full-spectrum asset inspection is realized by merging the data from all three domains (air, land, sea) into one cohesive, predictive platform. Data Fusion: We combine the DTMs (Land), the UT measurements (Air), and the sonar/scour data (Sea) into a unified dataset. The Digital Twin: This unified dataset creates the Digital Twin, a living, virtual replica of the entire asset portfolio. This advanced digital model allows asset managers to move beyond simple mapping and into true simulation. Value and RUL: The Digital Twin enables managers to perform remaining useful life (RUL) calculations and simulate future structural degradation. This unified approach provides objective, predictive maintenance insights, allowing clients to replace emergency spending with proactive, optimized resource allocation across the entire asset portfolio. Securing Integrity and Leadership The transition to a digital, holistic inspection strategy is essential for securing operational longevity and supporting Vision 2030’s infrastructure goals. Implement a full-spectrum asset inspection strategy of your infrastructure for long-term safety, efficiency, and predictive control. Let’s Talk!

The Coastal Imperative: Why ROV-Based Monitoring is Essential for Maintaining Saudi Vision 2030’s Offshore and Port Infrastructure.

The Challenge Beneath the Surface The foundations of the MENA economy, jetties, bridges, seawalls, port facilities, and offshore energy platforms. They rely on submerged infrastructure. These assets face a brutal, unseen enemy: the marine environment. Constant exposure to seawater, which is highly corrosive, leads to material loss. This structural decay is worsened by biofouling, the rapid growth of marine organisms that attach to surfaces and accelerate corrosion. These environmental stressors lead to structural fatigue and threaten the longevity of vital infrastructure. The traditional approach to inspection only compounds the problem: Safety, Risk, and Accessibility: Inspecting submerged assets typically requires human divers. This process is inherently risky due to high currents, low visibility, and deep or confined spaces e.g. storage tank. Human divers are physically limited in depth and endurance, restricting their bottom time to one or two hours. High Cost and Downtime: Diver-based inspections are costly and time-consuming, requiring extensive coordination and specialized teams. For assets like fuel tanks, inspection often requires draining the tank, halting operations, and causing significant revenue loss. Data Quality: Diver reports are often subjective, lack precise location data (geotagging), and are difficult for engineers to rely on for long-term predictive models. The region urgently needs a safer, more efficient, and data-driven way to manage its critical maritime assets. The Rise of ROV-Based Monitoring Remotely Operated Vehicles (ROVs) are robotic systems that are transforming underwater inspection workflows by eliminating the need for human presence in high-risk zones. This technology has moved from specialized offshore use to become the standard for routine ROV-based monitoring for marine inspection assets. I. Advanced Technologies for Unseen Environments Inspection-class ROVs are compact, agile, and equipped with a versatile sensor suite designed to overcome the limitations of the marine environment. Visual and Sonar Imaging: ROVs use high-definition cameras and bright LED lighting to provide unparalleled visibility in clear water. More critically, they carry multibeam or scanning sonar for navigation and imaging in areas with poor visibility, such as murky water or sediment-rich areas. Sonar emits sound waves to create a clear picture of the environment, even when the operator cannot see. Navigation and Positioning: Advanced systems leverage DVL (Doppler Velocity Log) and U-INS (Underwater Inertial Navigation System) to ensure stable control and precise positioning. This means the ROV can hover automatically in turbulent conditions and record the exact GPS coordinates of every finding (geotagging), allowing for easier data correlation later. Core Payloads: ROVs are modular and can carry essential tools, including laser scaling devices for precise measurement, environmental sensors (temperature, salinity), and Ultrasonic Thickness (UT) gauges for Non-Destructive Testing (NDT). II. Applications Across Marine Infrastructure ROV-based monitoring for marine inspection assets is suitable for virtually all submerged structures: Port Facilities and Jetties: ROVs inspect submerged concrete degradation, scour (erosion around foundations), joint separations, and piling integrity. Offshore Energy: They assess corrosion, marine growth, and cathodic protection anodes around platform jackets, risers, and offshore wind turbine foundations. Vessels and Confined Spaces: Shipowners use ROVs for underwater hull inspection and ballast tank checks, often eliminating the need for costly dry docking. Pipelines and Cables: ROVs perform routine checks for corrosion, sediment buildup, structural anomalies, and accurate depth-of-burial surveys. From Reactive to Predictive Maintenance The immediate deployment and continuous operation of ROVs transform asset care from a reactive, emergency response into a proactive, data-driven strategy. III. Enabling Proactive Asset Management Reduced Human Risk and Downtime: The primary gain is safety. ROVs operate in challenging conditions such as extreme depths, high currents, and contaminated waters, eliminating risks to human divers. Furthermore, ROVs can be deployed in minutes and operate continuously without the time restrictions of human divers, ensuring operational continuity. Quantitative Corrosion and Damage Assessment: Equipped with UT gauges, ROVs perform precise NDT, measuring wall thickness to determine corrosion and material loss. The data collected is highly traceable and auditable. Continuous Monitoring for Early Detection: The low cost and rapid deployment encourage more frequent inspections. This continuous monitoring allows owners to detect minor anomalies early, preventing small cracks or corrosion spots from escalating into severe structural failures. Digital Twin Integration: The high-resolution video, sonar images, and UT measurements are stored in cloud platforms like Terra 3D Inspect. This data builds and updates the asset’s digital twin, a virtual replica that allows managers to run simulations, forecast structural decay, and schedule maintenance precisely, maximizing the asset’s lifespan. IV. Powering the Underwater Inspection The ability to successfully transition to predictive maintenance relies entirely on the quality and stability of the hardware capturing the data. For high-stakes subsea inspection, Terra Drone Arabia partners with world-leading technology providers to ensure mission success. This is where the specialized capabilities of QYSEA robotic systems come into play. A. The Precision Platform The QYSEA W6 NAVI is a specialized Maritime ROV designed to bring precision and versatility to the challenging conditions of open-sea environments and complex port facilities. This system acts as a central data hub, ensuring stable and reliable acquisition for all subsea inspection data. The W6 NAVI’s technical capabilities directly support the advanced requirements of ROV-based monitoring for marine inspection assets: Precise Navigation and Stability: The system enables precise navigation and enhanced hovering stability. This is critical for performing detailed work near structures, especially in high-current or turbulent waters where manual control is difficult. Robust Surveys: The W6 NAVI supports robust surveys and automated operations. This allows the platform to perform continuous, repeatable inspection paths, ensuring consistent data quality for comparative analysis over time. Open Sea Versatility: Its design specifically handles the demands of open-sea environments. This confirms its suitability for inspecting offshore assets and long subsea pipelines that require working far from shore. Full Asset Visibility Integration: The high-quality, geotagged data collected by the W6 NAVI is essential for the holistic approach. This data is integrated with aerial (drone LiDAR) and terrestrial data, ensuring full 360° asset visibility. By deploying specialized tools like the QYSEA W6 NAVI, we ensure that every inspection mission from scour assessment to hull integrity is conducted with the highest levels of stability and data

ROV-Based Monitoring for Marine Infrastructure and Coastal Inspection Assets

The Challenge Beneath the Surface The foundations of the MENA economy—jetties, bridges, seawalls, port facilities, and offshore energy platforms—rely on submerged infrastructure. These assets face a brutal, unseen enemy: the marine environment. Constant exposure to seawater, which is highly corrosive, leads to material loss. This structural decay is worsened by biofouling—the rapid growth of marine organisms that attach to surfaces and accelerate corrosion. These environmental stressors lead to structural fatigue and threaten the longevity of vital infrastructure. The traditional approach to inspection only compounds the problem: Safety, Risk, and Accessibility: Inspecting submerged assets typically requires human divers. This process is inherently risky due to high currents, low visibility, and deep or confined spaces. Human divers are physically limited in depth and endurance, restricting their bottom time to one or two hours. High Cost and Downtime: Diver-based inspections are costly and time-consuming, requiring extensive coordination and specialized teams. For assets like fuel tanks, inspection often requires draining the tank, halting operations, and causing significant revenue loss. Data Quality: Diver reports are often subjective, lack precise location data (geotagging), and are difficult for engineers to rely on for long-term predictive models. The region urgently needs a safer, more efficient, and data-driven way to manage its critical maritime assets. The Rise of ROV-Based Monitoring Remotely Operated Vehicles (ROVs) are robotic systems that are transforming underwater inspection workflows by eliminating the need for human presence in high-risk zones. This technology has moved from specialized offshore use to become the standard for routine ROV-based monitoring for marine inspection assets. I. Advanced Technologies for Unseen Environments Inspection-class ROVs are compact, agile, and equipped with a versatile sensor suite designed to overcome the limitations of the marine environment. Visual and Sonar Imaging: ROVs use high-definition cameras and bright LED lighting to provide unparalleled visibility in clear water. More critically, they carry multibeam or scanning sonar for navigation and imaging in areas with poor visibility, such as murky water or sediment-rich areas. Sonar emits sound waves to create a clear picture of the environment, even when the operator cannot see. Navigation and Positioning: Advanced systems leverage DVL (Doppler Velocity Log) and U-INS (Underwater Inertial Navigation System) to ensure stable control and precise positioning. This means the ROV can hover automatically in turbulent conditions and record the exact GPS coordinates of every finding (geotagging), allowing for easier data correlation later. Core Payloads: ROVs are modular and can carry essential tools, including laser scaling devices for precise measurement, environmental sensors (temperature, salinity), and Ultrasonic Thickness (UT) gauges for Non-Destructive Testing (NDT). II. Applications Across Marine Infrastructure ROV-based monitoring for marine inspection assets is suitable for virtually all submerged structures: Port Facilities and Jetties: ROVs inspect submerged concrete degradation, scour (erosion around foundations), joint separations, and piling integrity. Offshore Energy: They assess corrosion, marine growth, and cathodic protection anodes around platform jackets, risers, and offshore wind turbine foundations. Vessels and Confined Spaces: Shipowners use ROVs for underwater hull inspection and ballast tank checks, often eliminating the need for costly dry docking. Pipelines and Cables: ROVs perform routine checks for corrosion, sediment buildup, structural anomalies, and accurate depth-of-burial surveys. From Reactive to Predictive Maintenance The immediate deployment and continuous operation of ROVs transform asset care from a reactive, emergency response into a proactive, data-driven strategy. III. Enabling Proactive Asset Management Reduced Human Risk and Downtime: The primary gain is safety. ROVs operate in challenging conditions such as extreme depths, high currents, and contaminated waters, eliminating risks to human divers. Furthermore, ROVs can be deployed in minutes and operate continuously without the time restrictions of human divers, ensuring operational continuity. Quantitative Corrosion and Damage Assessment: Equipped with UT gauges, ROVs perform precise NDT, measuring wall thickness to determine corrosion and material loss. The data collected is highly traceable and auditable. Continuous Monitoring for Early Detection: The low cost and rapid deployment encourage more frequent inspections. This continuous monitoring allows owners to detect minor anomalies early, preventing small cracks or corrosion spots from escalating into severe structural failures. digital twin Integration: The high-resolution video, sonar images, and UT measurements are stored in cloud platforms like Terra 3D Inspect. This data builds and updates the asset’s digital twin, a virtual replica that allows managers to run simulations, forecast structural decay, and schedule maintenance precisely, maximizing the asset’s lifespan. IV. Synergy with Full Asset Visibility The underwater data is far more valuable when combined with aerial and terrestrial data. Our workflow integrates ROV bathymetry and scour data with drone LiDAR surveys of the dry dock and pier structures above the water line. This holistic approach provides complete, 360° asset visibility, moving beyond the subsea environment alone. Advancing Coastal Resilience with Smart Inspection The integration of remote technology is no longer optional; it is essential for supporting sustainable coastal and offshore infrastructure development under Saudi Vision 2030. Adoption Mandate: Organizations must adopt ROV-based monitoring for marine inspection assets as a cornerstone of their asset integrity programs. The cost benefits, avoiding drainage, reducing labor, and preventing downtime far exceed the cost of the technology itself, often providing a payback period of less than one year. Standardization and Integration: We encourage the integration of ROV data into existing GIS and digital twin systems for seamless lifecycle tracking. Partnering for Expertise: Terra Drone Arabia offers a complete suite of solutions, combining specialized expertise in subsea data acquisition with world-leading technology. We partner with innovators like QYSEA Technology to utilize ROVs (like the FIFISH Expert series) that are compact, maneuverable, and equipped with AI-enabled navigation and sonar systems. Our certified team ensures safe, efficient deployment and delivers actionable insights. Secure the long-term integrity of your marine assets. Contact us to discuss implementing an ROV pilot program and transforming your maintenance strategy from reactive to predictive.

Save 95℅ Time with Drone-Based Corrosion Inspection for Assets

The Corrosion Inspection Challenge Corrosion is the silent and relentless enemy of metal assets—it remains the leading cause of unplanned shutdowns, containment failures, and devastating safety risks across the oil & gas, petrochemical, and heavy industrial sectors. In the demanding environments of the MENA region, assets like storage tanks, pipelines, and flare stacks face extreme pressure and must maintain peak structural integrity. The conventional methods for fighting corrosion are simply no longer good enough. Scaffolding and Time: Traditional inspections require extensive, costly scaffolding or rope access, shutting down operations for days or weeks. This severely impacts productivity. Safety Risks: Inspectors must enter hazardous confined spaces or climb hundreds of meters above the ground, exposing them to significant dangers. Manual Data: Manual Ultrasonic Thickness (UT) checks are subjective, slow, and often provide data that is difficult to trace and integrate into digital asset management systems. Industry urgently needs a safer, faster, and more data-rich way to assess asset health. The solution is the convergence of aerial technology and specialized testing: corrosion inspection with drone-based visual and UT systems. Integrating Visual and Ultrasonic Thickness (UT) Drones The future of asset integrity lies in non-contact aerial access combined with contact-based measurement precision. Drone technology now provides a complete, two-part inspection solution. I. High-Resolution Visual Inspection Visual drones start the process by quickly capturing comprehensive data on the asset’s exterior. Complete Coverage: Drones fly precise, automated paths around tanks, pipelines, and stacks, collecting high-resolution imagery. This imagery builds a precise 3D model (photogrammetry) of the asset. Defect Mapping: Specialized cameras detect and map all surface defects, such as paint degradation, coating loss, signs of external corrosion, and cracking. This creates a digital record showing the location and size of every visible fault. Efficiency Metric: By eliminating the manual setup time, drone technology can reduce the time required for complex tank or flare stack inspections by up to 95% compared to traditional scaffolding or rope access methods, delivering immediate time and cost savings. II. Drone Equipment Solution: The Hardware Behind the Data Terra Drone Arabia delivers advanced results by operating both proprietary solutions and specialized hardware designed for harsh industrial environments. Our fleet is purpose-built to execute both visual and contact-based NDT with exceptional stability and accuracy. Visual Platforms: For initial high-resolution assessment and long-range mapping, our solutions rely on robust, enterprise-grade multirotor platforms. These systems carry high-resolution cameras and thermal sensors, enabling fast, safe visual coverage of vast industrial footprints. Voliro T for Contact NDT: For vital external contact-based measurements, we deploy the Voliro T drone. This aerial robotic platform is uniquely engineered with omnidirectional flight capabilities and tiltable rotors. This allows the drone to apply stable, measurable force to vertical or overhead metal surfaces for accurate UT measurement. Terra Xross 1 for Confined Space: For internal, indoor inspections where GPS signals fail, we use the Terra Xross 1. This drone features a protective cage and specialized sensors to navigate safely inside tanks, vessels, and chimneys. It collects vital visual data in dark, enclosed spaces, eliminating the need for human entry into hazardous atmospheres. III. Ultrasonic Thickness (UT) for Material Loss The crucial step for determining true structural integrity is measuring wall thickness. Advanced aerial robotic platforms like the Voliro T now perform this Non-Destructive Testing (NDT) task. Contact Measurement: The Voliro T drone carefully approaches the metal surface of the asset be it the roof of a storage tank or a vertical wall and gently places a contact sensor on the surface. This stable contact allows the Voliro T to measure the wall thickness from the outside. Corrosion Detection: By comparing this measured thickness to the original blueprint specification, we immediately detect corrosion and material loss. This confirms whether the asset remains structurally sound. Data Traceability: The UT reading is captured digitally, stamped with its exact GPS location, and immediately linked to a photograph of the contact point. This provides auditable data that meets the strict traceability requirements of industry standards. Technical and Operational Benefits Adopting corrosion inspection with drone-based visual and UT systems delivers clear, quantifiable advantages for safety, finance, and long-term planning. IV. Technical and Operational Benefits of Drone NDT The fusion of aerial access and digital NDT transforms risk management into a strategic asset. A. Safety and Efficiency Gains Zero High-Altitude Risk: Drones perform all inspections—from pipe racks to flare stack tips—without putting a single worker at risk of falling or entering a dangerous atmosphere. Confined Space Safety: Using drones like the Terra Xross 1 for internal inspections ensures personnel do not enter hazardous vessels, directly solving a major industry safety issue. Minimal Shutdown Time: Drones perform inspections much faster, allowing facilities to maintain operational continuity. This significantly cuts downtime and maximizes productivity. This enhanced safety record supports ISO 45001 occupational health standards. Efficiency: Drone inspection missions are quick. When compared to the weeks needed for scaffolding, drone operations reduce inspection time by up to 70% for an asset, saving labor and rental costs. B. Accuracy and Predictive Maintenance Consistent Data: Drone flight paths are automated and repeatable. This ensures every inspection captures data from the exact same location as the previous one, providing reliable change detection over time. Traceable UT Data: Drone UT data is recorded with precise GPS location and photo documentation, providing level 3 traceability that meets API 653 standards, which governs above-ground storage tank inspection. This removes the subjectivity often found in manual reports. digital twin Integration: All visual maps, defect locations, and UT thickness measurements are immediately integrated into the asset’s digital twin. This living replica allows managers to perform predictive maintenance and accurately calculate the asset’s remaining useful life (RUL). C. Compliance and Standardization The use of drone technology supports major regulatory frameworks, ensuring structural integrity compliance. Integrity Standards: Drone NDT techniques support inspection requirements under standards such as API 653 (Storage Tanks) and ISO 9712 (Qualification of NDT Personnel). Standardization: As drone technology matures, collaborating with inspection bodies helps standardize these UAV-based NDT workflows, securing the technology’s place as a primary integrity

Revolutionizing Corrosion Inspection With Drone-based Visual and UT Systems

The Corrosion Inspection Challenge Corrosion is the silent and relentless enemy of metal assets—remains the leading cause of unplanned shutdowns, containment failures, and devastating safety risks across the oil & gas, petrochemical, and heavy industrial sectors. In the demanding environments of the MENA region, assets like storage tanks, pipelines, and flare stacks face extreme pressure and must maintain peak structural integrity. The conventional methods for fighting corrosion are simply no longer good enough. Scaffolding and Time: Traditional inspections require extensive, costly scaffolding or rope access, shutting down operations for days or weeks. This severely impacts productivity. Safety Risks: Inspectors must enter hazardous confined spaces or climb hundreds of meters above the ground, exposing them to significant dangers. Manual Data: Manual Ultrasonic Thickness (UT) checks are subjective, slow, and often provide data that is difficult to trace and integrate into digital asset management systems. Industry urgently needs a safer, faster, and more data-rich way to assess asset health. The solution is the convergence of aerial technology and specialized testing: corrosion inspection with drone-based visual and UT systems. Integrating Visual and Ultrasonic Thickness (UT) Drones The future of asset integrity lies in non-contact aerial access combined with contact-based measurement precision. Drone technology now provides a complete, two-part inspection solution. I. High-Resolution Visual Inspection Visual drones start the process by quickly capturing comprehensive data on the asset’s exterior. Complete Coverage: Drones fly precise, automated paths around tanks, pipelines, and stacks, collecting high-resolution imagery. This imagery builds a precise 3D model (photogrammetry) of the asset. Defect Mapping: Specialized cameras detect and map all surface defects, such as paint degradation, coating loss, signs of external corrosion, and cracking. This creates a digital record showing the location and size of every visible fault. Efficiency Metric: By eliminating the manual setup time, drone technology can reduce the time required for complex tank or flare stack inspections by up to 95% compared to traditional scaffolding or rope access methods, delivering immediate time and cost savings. II. Drone Equipment Solution: The Hardware Behind the Data (New Section) Terra Drone Arabia delivers advanced results by operating both proprietary solutions and best-in-class specialized hardware designed for harsh industrial environments. Our fleet is purpose-built to execute both visual and contact-based NDT with exceptional stability and accuracy. A. Voliro T for Contact NDT For vital contact-based measurements, we deploy the Voliro T drone. Unique Design: The Voliro T is an aerial robotic platform uniquely engineered with omnidirectional flight capabilities and tiltable rotors. This allows the drone to approach vertical or overhead metal surfaces from any angle and apply stable, measurable force. UT Payload: The Voliro T, equipped with an Ultrasonic Transducer (UT) probe, performs precise, stable contact NDT. This specialized function is essential for accurate wall thickness measurement in high-altitude areas. B. High-Endurance Visual Platforms For long-range corridor mapping and initial high-resolution visual assessment, our inspection solutions rely on robust, enterprise-grade multirotor platforms. These systems carry high-resolution cameras and thermal sensors, enabling fast, safe visual coverage of vast industrial footprints and linear pipelines. C. Ultrasonic Thickness (UT) for Material Loss The crucial step for determining true structural integrity is measuring wall thickness. The Voliro T now performs this Non-Destructive Testing (NDT) task. Contact Measurement: The Voliro T drone carefully approaches the metal surface of the asset, be it the roof of a storage tank or a vertical wall—and gently places a contact sensor on the surface. This stable contact allows the Voliro T to measure the wall thickness from the outside. Corrosion Detection: By comparing this measured thickness to the original blueprint specification, we immediately detect corrosion and material loss. This confirms whether the asset remains structurally sound. Data Traceability: The UT reading is captured digitally, stamped with its exact GPS location, and immediately linked to a photograph of the contact point. This provides auditable data that meets the strict traceability requirements of industry standards. Technical and Operational Benefits Adopting corrosion inspection with drone-based visual and UT systems delivers clear, quantifiable advantages for safety, finance, and long-term planning. III. Technical and Operational Benefits of Drone NDT The fusion of aerial access and digital NDT transforms risk management into a strategic asset. A. Safety and Efficiency Gains Zero High-Altitude Risk: Drones like the Voliro T perform all inspections—from pipe racks to flare stack tips—without putting a single worker at risk of falling or entering a dangerous atmosphere. Minimal Shutdown Time: Drones perform inspections much faster, allowing facilities to maintain operational continuity. This significantly cuts downtime and maximizes productivity. This enhanced safety record supports ISO 45001 occupational health standards. Efficiency: Drone inspection missions are quick. When compared to the weeks needed for scaffolding, drone operations reduce inspection time by up to 70% for an asset, saving labor and rental costs. B. Accuracy and Predictive Maintenance Consistent Data: Drone flight paths are automated and repeatable. This ensures every inspection captures data from the exact same location as the previous one, providing reliable change detection over time. Traceable UT Data: Drone UT data is recorded with precise GPS location and photo documentation, providing level 3 traceability that meets API 653 standards, which governs above-ground storage tank inspection. This removes the subjectivity often found in manual reports. Digital Twin Integration: All visual maps, defect locations, and UT thickness measurements are immediately integrated into the asset’s digital twin. This living replica allows managers to perform predictive maintenance and accurately calculate the asset’s remaining useful life (RUL). C. Compliance and Standardization The use of drone technology supports major regulatory frameworks, ensuring structural integrity compliance. Integrity Standards: Drone NDT techniques support inspection requirements under standards such as API 653 (Storage Tanks) and ISO 9712 (Qualification of NDT Personnel). Standardization: As drone technology matures, collaborating with inspection bodies helps standardize these UAV-based NDT workflows, securing the technology’s place as a primary integrity tool. Toward Intelligent Corrosion Management The era of slow, dangerous, and subjective industrial inspections is ending. The high-resolution, centimeter-accurate data delivered by corrosion inspection with drone-based visual and UT systems is the central component of intelligent asset management strategies

How Geospatial Intelligence Powers Predictive Asset Management

The Operational Imperative The moment infrastructure like highways, bridges, and industrial assets finish construction, they enter a critical new phase: operational risk. Managing maintenance is the single largest long-term cost, and reactive failure, waiting for a fault before fixing it is unacceptable for any modern smart city. The challenge lies in inspection. Traditional integrity checks are slow, subjective, and inherently dangerous. They require costly actions like building scaffolding or closing traffic lanes. This process delivers low-volume, outdated data, locking asset managers into a dangerous cycle of reactive failure. The only effective solution is the digital twin, a virtual replica built on persistent, high-quality data. This digital twin, fueled by geospatial intelligence for smart city data, enables the fundamental shift to safe, objective, and predictive maintenance. The Data Foundation for Asset Integrity The operational success of a highway or an industrial plant starts with the quality of its initial survey data. This information creates the digital foundation for the entire asset lifecycle. I. Establishing the Digital Baseline for RUL Calculation All reliable long-term maintenance must start with a perfect measurement of the asset’s original, healthy state. A. The Geospatial Baseline The initial centimeter-accurate survey data collected using drone-based LiDAR and Photogrammetry creates the indispensable structural health baseline. This initial data is the only reference point against which all future material wear, structural cracks, and component degradation are measured. Without this accurate baseline, calculating deterioration is impossible. B. Data Chronology for RUL The ultimate goal of asset management is accurately forecasting failure. This is done through remaining useful life (RUL) calculation. RUL Definition: The RUL predicts how much longer an asset can operate safely before maintenance or replacement is necessary. Data Necessity: Accurately calculating RUL requires a consistent, chronological data feed. Drone technology provides this through repeatable missions (weekly or monthly flights) that document changes over time. Cost Benefit: Using this predictive data allows companies to shift maintenance spending from sudden, expensive emergencies to planned, controlled projects, maximizing the useful life of the asset. Advanced Integrity Checks and Simulation The Digital Twin’s predictive power is unlocked by combining the initial baseline data with continuous, non-contact integrity checks. II. Non-Contact Integrity and Defect Detection Drones perform essential, high-risk inspections without ever endangering human personnel or halting operations. A. Structural Health Monitoring Bridge Scanning: Drones fly precise, automated flight paths beneath complex highway structures and bridges. This non-contact method eliminates the cost of scaffolding and the risk of lane closures. Visual Data: High-resolution cameras scan for tiny surface defects like concrete cracks, spalling, and corrosion. Drone inspections can reduce asset inspection times by 4 times compared to manual methods, allowing for more frequent and proactive maintenance checks. Pavement Analysis: High-resolution drone cameras collect data used to map and classify pavement damage, such as cracking and rutting. This detailed information helps transportation agencies prioritize road repairs effectively. B. Specialized Non-Destructive Testing (NDT) Advanced payloads allow for structural health checks beyond simple visual inspection. Thermal Imaging: Thermal cameras detect temperature variations on surfaces like pavements or bridge decks. These temperature differences often reveal subsurface issues like water intrusion, poor drainage, or voids beneath the roadbed that human eyes cannot see. Early thermal mapping prevents minor moisture issues from growing into major structural failures. Confined Space Safety: Using small, specialized drones, we inspect hazardous and enclosed assets like boilers, storage tank interiors, and industrial vessels. This capability eliminates human risk and minimizes costly operational shutdown time. Drone UT: Drones equipped with ultrasonic thickness (UT) probes perform non-contact measurement of material thinning and corrosion in assets like storage tanks and pipe. This provides critical input for the predictive maintenance model. C. Predictive Simulation (The Digital Twin at Work) The Digital Twin consumes all this recurring inspection data (baseline + defects) to run simulations. Forecasting Failure: The twin runs predictive models that forecast when a structural element will reach its critical threshold (RUL). This allows asset managers to schedule repairs precisely, maximizing the useful life of the asset while minimizing costly downtime. Centralized Management: This platform ensures that all parts of the future smart city operate cohesively and efficiently, confirming that the foundation of the system is robust, up-to-date Geospatial Intelligence for Smart City data. Secure Your Operational Future The digital transformation of asset management moves highway and infrastructure care from reactive to predictive, objective, and safe. The use of continuous geospatial intelligence for smart city platforms ensures that infrastructure remains durable, efficient, and compliant with long-term goals. Terra Drone Arabia is your certified local partner. We possess the needed technical capacity and local compliance knowledge to deliver comprehensive geospatial data for every inspection mission. Accelerate your shift to predictive asset management and experience these efficiency gains with FREE 3-month progress monitoring on a key bridge or highway section. Let’s talk to your future-proof critical transportation network.