The Coastal Imperative: Why ROV-Based Monitoring is Essential for Maintaining Saudi Vision 2030’s Offshore and Port Infrastructure.

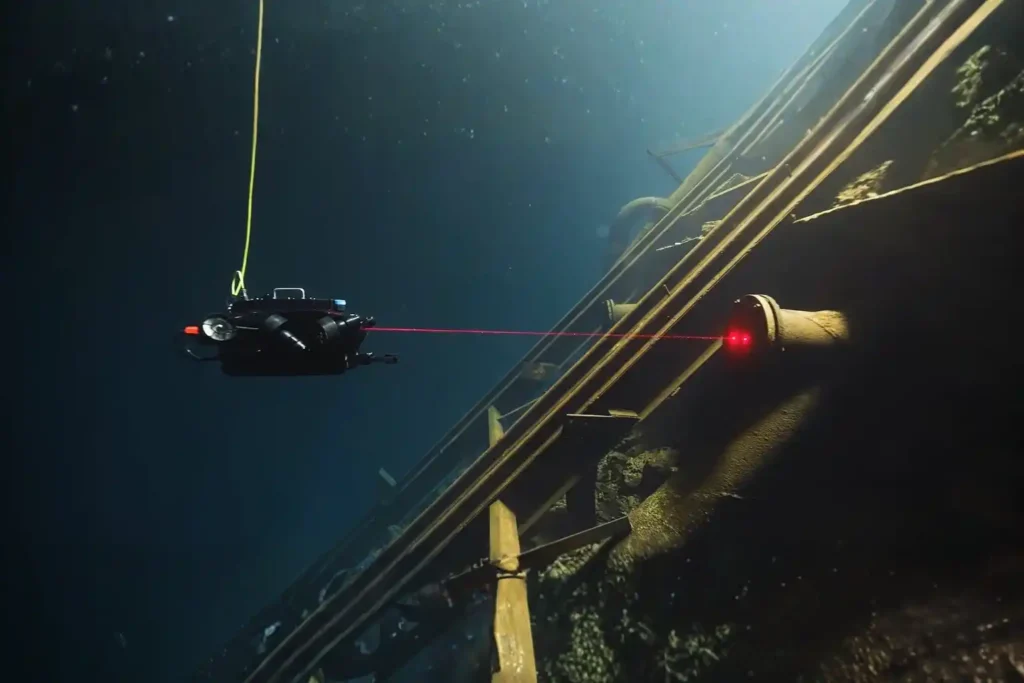

The Challenge Beneath the Surface The foundations of the MENA economy, jetties, bridges, seawalls, port facilities, and offshore energy platforms. They rely on submerged infrastructure. These assets face a brutal, unseen enemy: the marine environment. Constant exposure to seawater, which is highly corrosive, leads to material loss. This structural decay is worsened by biofouling, the rapid growth of marine organisms that attach to surfaces and accelerate corrosion. These environmental stressors lead to structural fatigue and threaten the longevity of vital infrastructure. The traditional approach to inspection only compounds the problem: Safety, Risk, and Accessibility: Inspecting submerged assets typically requires human divers. This process is inherently risky due to high currents, low visibility, and deep or confined spaces e.g. storage tank. Human divers are physically limited in depth and endurance, restricting their bottom time to one or two hours. High Cost and Downtime: Diver-based inspections are costly and time-consuming, requiring extensive coordination and specialized teams. For assets like fuel tanks, inspection often requires draining the tank, halting operations, and causing significant revenue loss. Data Quality: Diver reports are often subjective, lack precise location data (geotagging), and are difficult for engineers to rely on for long-term predictive models. The region urgently needs a safer, more efficient, and data-driven way to manage its critical maritime assets. The Rise of ROV-Based Monitoring Remotely Operated Vehicles (ROVs) are robotic systems that are transforming underwater inspection workflows by eliminating the need for human presence in high-risk zones. This technology has moved from specialized offshore use to become the standard for routine ROV-based monitoring for marine inspection assets. I. Advanced Technologies for Unseen Environments Inspection-class ROVs are compact, agile, and equipped with a versatile sensor suite designed to overcome the limitations of the marine environment. Visual and Sonar Imaging: ROVs use high-definition cameras and bright LED lighting to provide unparalleled visibility in clear water. More critically, they carry multibeam or scanning sonar for navigation and imaging in areas with poor visibility, such as murky water or sediment-rich areas. Sonar emits sound waves to create a clear picture of the environment, even when the operator cannot see. Navigation and Positioning: Advanced systems leverage DVL (Doppler Velocity Log) and U-INS (Underwater Inertial Navigation System) to ensure stable control and precise positioning. This means the ROV can hover automatically in turbulent conditions and record the exact GPS coordinates of every finding (geotagging), allowing for easier data correlation later. Core Payloads: ROVs are modular and can carry essential tools, including laser scaling devices for precise measurement, environmental sensors (temperature, salinity), and Ultrasonic Thickness (UT) gauges for Non-Destructive Testing (NDT). II. Applications Across Marine Infrastructure ROV-based monitoring for marine inspection assets is suitable for virtually all submerged structures: Port Facilities and Jetties: ROVs inspect submerged concrete degradation, scour (erosion around foundations), joint separations, and piling integrity. Offshore Energy: They assess corrosion, marine growth, and cathodic protection anodes around platform jackets, risers, and offshore wind turbine foundations. Vessels and Confined Spaces: Shipowners use ROVs for underwater hull inspection and ballast tank checks, often eliminating the need for costly dry docking. Pipelines and Cables: ROVs perform routine checks for corrosion, sediment buildup, structural anomalies, and accurate depth-of-burial surveys. From Reactive to Predictive Maintenance The immediate deployment and continuous operation of ROVs transform asset care from a reactive, emergency response into a proactive, data-driven strategy. III. Enabling Proactive Asset Management Reduced Human Risk and Downtime: The primary gain is safety. ROVs operate in challenging conditions such as extreme depths, high currents, and contaminated waters, eliminating risks to human divers. Furthermore, ROVs can be deployed in minutes and operate continuously without the time restrictions of human divers, ensuring operational continuity. Quantitative Corrosion and Damage Assessment: Equipped with UT gauges, ROVs perform precise NDT, measuring wall thickness to determine corrosion and material loss. The data collected is highly traceable and auditable. Continuous Monitoring for Early Detection: The low cost and rapid deployment encourage more frequent inspections. This continuous monitoring allows owners to detect minor anomalies early, preventing small cracks or corrosion spots from escalating into severe structural failures. Digital Twin Integration: The high-resolution video, sonar images, and UT measurements are stored in cloud platforms like Terra 3D Inspect. This data builds and updates the asset’s digital twin, a virtual replica that allows managers to run simulations, forecast structural decay, and schedule maintenance precisely, maximizing the asset’s lifespan. IV. Powering the Underwater Inspection The ability to successfully transition to predictive maintenance relies entirely on the quality and stability of the hardware capturing the data. For high-stakes subsea inspection, Terra Drone Arabia partners with world-leading technology providers to ensure mission success. This is where the specialized capabilities of QYSEA robotic systems come into play. A. The Precision Platform The QYSEA W6 NAVI is a specialized Maritime ROV designed to bring precision and versatility to the challenging conditions of open-sea environments and complex port facilities. This system acts as a central data hub, ensuring stable and reliable acquisition for all subsea inspection data. The W6 NAVI’s technical capabilities directly support the advanced requirements of ROV-based monitoring for marine inspection assets: Precise Navigation and Stability: The system enables precise navigation and enhanced hovering stability. This is critical for performing detailed work near structures, especially in high-current or turbulent waters where manual control is difficult. Robust Surveys: The W6 NAVI supports robust surveys and automated operations. This allows the platform to perform continuous, repeatable inspection paths, ensuring consistent data quality for comparative analysis over time. Open Sea Versatility: Its design specifically handles the demands of open-sea environments. This confirms its suitability for inspecting offshore assets and long subsea pipelines that require working far from shore. Full Asset Visibility Integration: The high-quality, geotagged data collected by the W6 NAVI is essential for the holistic approach. This data is integrated with aerial (drone LiDAR) and terrestrial data, ensuring full 360° asset visibility. By deploying specialized tools like the QYSEA W6 NAVI, we ensure that every inspection mission from scour assessment to hull integrity is conducted with the highest levels of stability and data