ROV-Based Monitoring for Marine Infrastructure and Coastal Inspection Assets

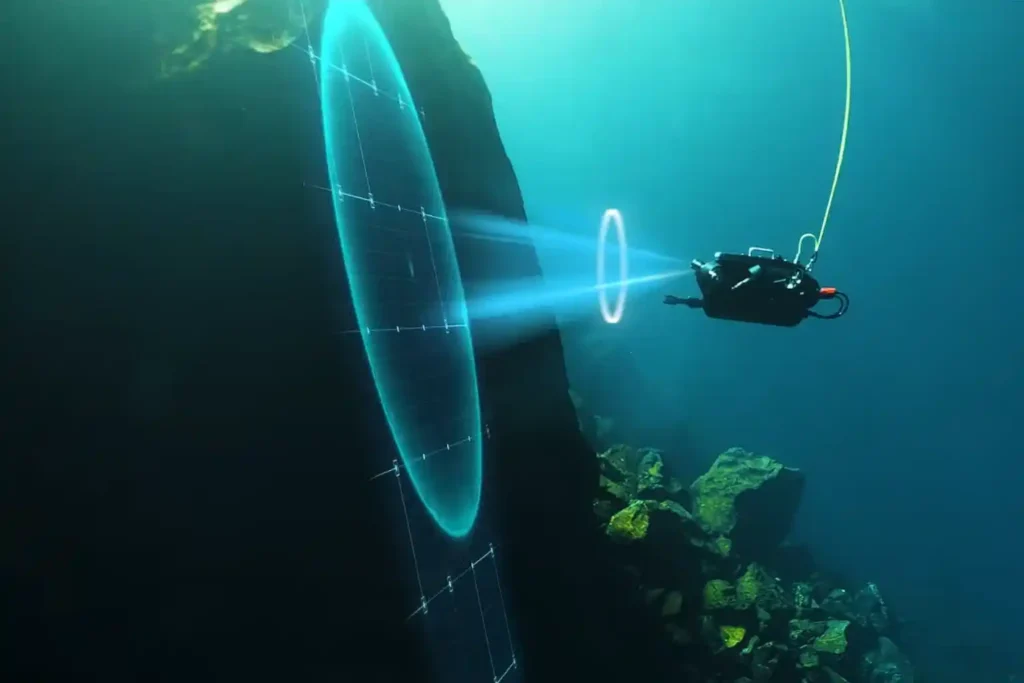

The Challenge Beneath the Surface The foundations of the MENA economy—jetties, bridges, seawalls, port facilities, and offshore energy platforms—rely on submerged infrastructure. These assets face a brutal, unseen enemy: the marine environment. Constant exposure to seawater, which is highly corrosive, leads to material loss. This structural decay is worsened by biofouling—the rapid growth of marine organisms that attach to surfaces and accelerate corrosion. These environmental stressors lead to structural fatigue and threaten the longevity of vital infrastructure. The traditional approach to inspection only compounds the problem: Safety, Risk, and Accessibility: Inspecting submerged assets typically requires human divers. This process is inherently risky due to high currents, low visibility, and deep or confined spaces. Human divers are physically limited in depth and endurance, restricting their bottom time to one or two hours. High Cost and Downtime: Diver-based inspections are costly and time-consuming, requiring extensive coordination and specialized teams. For assets like fuel tanks, inspection often requires draining the tank, halting operations, and causing significant revenue loss. Data Quality: Diver reports are often subjective, lack precise location data (geotagging), and are difficult for engineers to rely on for long-term predictive models. The region urgently needs a safer, more efficient, and data-driven way to manage its critical maritime assets. The Rise of ROV-Based Monitoring Remotely Operated Vehicles (ROVs) are robotic systems that are transforming underwater inspection workflows by eliminating the need for human presence in high-risk zones. This technology has moved from specialized offshore use to become the standard for routine ROV-based monitoring for marine inspection assets. I. Advanced Technologies for Unseen Environments Inspection-class ROVs are compact, agile, and equipped with a versatile sensor suite designed to overcome the limitations of the marine environment. Visual and Sonar Imaging: ROVs use high-definition cameras and bright LED lighting to provide unparalleled visibility in clear water. More critically, they carry multibeam or scanning sonar for navigation and imaging in areas with poor visibility, such as murky water or sediment-rich areas. Sonar emits sound waves to create a clear picture of the environment, even when the operator cannot see. Navigation and Positioning: Advanced systems leverage DVL (Doppler Velocity Log) and U-INS (Underwater Inertial Navigation System) to ensure stable control and precise positioning. This means the ROV can hover automatically in turbulent conditions and record the exact GPS coordinates of every finding (geotagging), allowing for easier data correlation later. Core Payloads: ROVs are modular and can carry essential tools, including laser scaling devices for precise measurement, environmental sensors (temperature, salinity), and Ultrasonic Thickness (UT) gauges for Non-Destructive Testing (NDT). II. Applications Across Marine Infrastructure ROV-based monitoring for marine inspection assets is suitable for virtually all submerged structures: Port Facilities and Jetties: ROVs inspect submerged concrete degradation, scour (erosion around foundations), joint separations, and piling integrity. Offshore Energy: They assess corrosion, marine growth, and cathodic protection anodes around platform jackets, risers, and offshore wind turbine foundations. Vessels and Confined Spaces: Shipowners use ROVs for underwater hull inspection and ballast tank checks, often eliminating the need for costly dry docking. Pipelines and Cables: ROVs perform routine checks for corrosion, sediment buildup, structural anomalies, and accurate depth-of-burial surveys. From Reactive to Predictive Maintenance The immediate deployment and continuous operation of ROVs transform asset care from a reactive, emergency response into a proactive, data-driven strategy. III. Enabling Proactive Asset Management Reduced Human Risk and Downtime: The primary gain is safety. ROVs operate in challenging conditions such as extreme depths, high currents, and contaminated waters, eliminating risks to human divers. Furthermore, ROVs can be deployed in minutes and operate continuously without the time restrictions of human divers, ensuring operational continuity. Quantitative Corrosion and Damage Assessment: Equipped with UT gauges, ROVs perform precise NDT, measuring wall thickness to determine corrosion and material loss. The data collected is highly traceable and auditable. Continuous Monitoring for Early Detection: The low cost and rapid deployment encourage more frequent inspections. This continuous monitoring allows owners to detect minor anomalies early, preventing small cracks or corrosion spots from escalating into severe structural failures. digital twin Integration: The high-resolution video, sonar images, and UT measurements are stored in cloud platforms like Terra 3D Inspect. This data builds and updates the asset’s digital twin, a virtual replica that allows managers to run simulations, forecast structural decay, and schedule maintenance precisely, maximizing the asset’s lifespan. IV. Synergy with Full Asset Visibility The underwater data is far more valuable when combined with aerial and terrestrial data. Our workflow integrates ROV bathymetry and scour data with drone LiDAR surveys of the dry dock and pier structures above the water line. This holistic approach provides complete, 360° asset visibility, moving beyond the subsea environment alone. Advancing Coastal Resilience with Smart Inspection The integration of remote technology is no longer optional; it is essential for supporting sustainable coastal and offshore infrastructure development under Saudi Vision 2030. Adoption Mandate: Organizations must adopt ROV-based monitoring for marine inspection assets as a cornerstone of their asset integrity programs. The cost benefits, avoiding drainage, reducing labor, and preventing downtime far exceed the cost of the technology itself, often providing a payback period of less than one year. Standardization and Integration: We encourage the integration of ROV data into existing GIS and digital twin systems for seamless lifecycle tracking. Partnering for Expertise: Terra Drone Arabia offers a complete suite of solutions, combining specialized expertise in subsea data acquisition with world-leading technology. We partner with innovators like QYSEA Technology to utilize ROVs (like the FIFISH Expert series) that are compact, maneuverable, and equipped with AI-enabled navigation and sonar systems. Our certified team ensures safe, efficient deployment and delivers actionable insights. Secure the long-term integrity of your marine assets. Contact us to discuss implementing an ROV pilot program and transforming your maintenance strategy from reactive to predictive.

Save 95℅ Time with Drone-Based Corrosion Inspection for Assets

The Corrosion Inspection Challenge Corrosion is the silent and relentless enemy of metal assets—it remains the leading cause of unplanned shutdowns, containment failures, and devastating safety risks across the oil & gas, petrochemical, and heavy industrial sectors. In the demanding environments of the MENA region, assets like storage tanks, pipelines, and flare stacks face extreme pressure and must maintain peak structural integrity. The conventional methods for fighting corrosion are simply no longer good enough. Scaffolding and Time: Traditional inspections require extensive, costly scaffolding or rope access, shutting down operations for days or weeks. This severely impacts productivity. Safety Risks: Inspectors must enter hazardous confined spaces or climb hundreds of meters above the ground, exposing them to significant dangers. Manual Data: Manual Ultrasonic Thickness (UT) checks are subjective, slow, and often provide data that is difficult to trace and integrate into digital asset management systems. Industry urgently needs a safer, faster, and more data-rich way to assess asset health. The solution is the convergence of aerial technology and specialized testing: corrosion inspection with drone-based visual and UT systems. Integrating Visual and Ultrasonic Thickness (UT) Drones The future of asset integrity lies in non-contact aerial access combined with contact-based measurement precision. Drone technology now provides a complete, two-part inspection solution. I. High-Resolution Visual Inspection Visual drones start the process by quickly capturing comprehensive data on the asset’s exterior. Complete Coverage: Drones fly precise, automated paths around tanks, pipelines, and stacks, collecting high-resolution imagery. This imagery builds a precise 3D model (photogrammetry) of the asset. Defect Mapping: Specialized cameras detect and map all surface defects, such as paint degradation, coating loss, signs of external corrosion, and cracking. This creates a digital record showing the location and size of every visible fault. Efficiency Metric: By eliminating the manual setup time, drone technology can reduce the time required for complex tank or flare stack inspections by up to 95% compared to traditional scaffolding or rope access methods, delivering immediate time and cost savings. II. Drone Equipment Solution: The Hardware Behind the Data Terra Drone Arabia delivers advanced results by operating both proprietary solutions and specialized hardware designed for harsh industrial environments. Our fleet is purpose-built to execute both visual and contact-based NDT with exceptional stability and accuracy. Visual Platforms: For initial high-resolution assessment and long-range mapping, our solutions rely on robust, enterprise-grade multirotor platforms. These systems carry high-resolution cameras and thermal sensors, enabling fast, safe visual coverage of vast industrial footprints. Voliro T for Contact NDT: For vital external contact-based measurements, we deploy the Voliro T drone. This aerial robotic platform is uniquely engineered with omnidirectional flight capabilities and tiltable rotors. This allows the drone to apply stable, measurable force to vertical or overhead metal surfaces for accurate UT measurement. Terra Xross 1 for Confined Space: For internal, indoor inspections where GPS signals fail, we use the Terra Xross 1. This drone features a protective cage and specialized sensors to navigate safely inside tanks, vessels, and chimneys. It collects vital visual data in dark, enclosed spaces, eliminating the need for human entry into hazardous atmospheres. III. Ultrasonic Thickness (UT) for Material Loss The crucial step for determining true structural integrity is measuring wall thickness. Advanced aerial robotic platforms like the Voliro T now perform this Non-Destructive Testing (NDT) task. Contact Measurement: The Voliro T drone carefully approaches the metal surface of the asset be it the roof of a storage tank or a vertical wall and gently places a contact sensor on the surface. This stable contact allows the Voliro T to measure the wall thickness from the outside. Corrosion Detection: By comparing this measured thickness to the original blueprint specification, we immediately detect corrosion and material loss. This confirms whether the asset remains structurally sound. Data Traceability: The UT reading is captured digitally, stamped with its exact GPS location, and immediately linked to a photograph of the contact point. This provides auditable data that meets the strict traceability requirements of industry standards. Technical and Operational Benefits Adopting corrosion inspection with drone-based visual and UT systems delivers clear, quantifiable advantages for safety, finance, and long-term planning. IV. Technical and Operational Benefits of Drone NDT The fusion of aerial access and digital NDT transforms risk management into a strategic asset. A. Safety and Efficiency Gains Zero High-Altitude Risk: Drones perform all inspections—from pipe racks to flare stack tips—without putting a single worker at risk of falling or entering a dangerous atmosphere. Confined Space Safety: Using drones like the Terra Xross 1 for internal inspections ensures personnel do not enter hazardous vessels, directly solving a major industry safety issue. Minimal Shutdown Time: Drones perform inspections much faster, allowing facilities to maintain operational continuity. This significantly cuts downtime and maximizes productivity. This enhanced safety record supports ISO 45001 occupational health standards. Efficiency: Drone inspection missions are quick. When compared to the weeks needed for scaffolding, drone operations reduce inspection time by up to 70% for an asset, saving labor and rental costs. B. Accuracy and Predictive Maintenance Consistent Data: Drone flight paths are automated and repeatable. This ensures every inspection captures data from the exact same location as the previous one, providing reliable change detection over time. Traceable UT Data: Drone UT data is recorded with precise GPS location and photo documentation, providing level 3 traceability that meets API 653 standards, which governs above-ground storage tank inspection. This removes the subjectivity often found in manual reports. digital twin Integration: All visual maps, defect locations, and UT thickness measurements are immediately integrated into the asset’s digital twin. This living replica allows managers to perform predictive maintenance and accurately calculate the asset’s remaining useful life (RUL). C. Compliance and Standardization The use of drone technology supports major regulatory frameworks, ensuring structural integrity compliance. Integrity Standards: Drone NDT techniques support inspection requirements under standards such as API 653 (Storage Tanks) and ISO 9712 (Qualification of NDT Personnel). Standardization: As drone technology matures, collaborating with inspection bodies helps standardize these UAV-based NDT workflows, securing the technology’s place as a primary integrity