Milestones to Watch in 2026 as Saudi Arabia Advances Vision 2030

The Year of Realization For the past seven years, the world has watched Saudi Arabia move earth and sand on a scale never seen before. We have witnessed the largest construction sites in history, from the mountains of Trojena to the coasts of the Red Sea. But as we approach 2026, the narrative is changing. 2026 is the tipping point. It is the year where “artist renderings” transform into “operational assets.” It is the year where the dust settles, and the cities come to life. This transition presents a new, critical challenge for developers and government entities. The focus shifts from “How do we build it fast?” to “How do we keep it running perfectly?” Achieving these Saudi Vision 2030 milestones requires a fundamental pivot in technology. We must move from construction support to operational intelligence. The tools that built the cities, such as drones, LiDAR, and digital models are now the tools that will sustain them. The stakes in 2026 are incredibly high. The Kingdom will not just be building; it will be hosting. With major global events on the horizon and tourists arriving, the reliability of infrastructure becomes the new currency. A failed air conditioning unit in a luxury resort or a structural issue in a theme park is no longer just a “snag list” item; it is an operational failure. To prevent this, asset managers must adopt a proactive, data-driven approach to maintenance immediately. The Deliverables of 2026 To understand the scale of the challenge, we must look at what is coming online. The sheer volume of infrastructure being delivered in 2026 is staggering, and each project brings unique maintenance demands. I. NEOM: The Vertical Challenge By 2026, the NEOM region will see significant activity. While the full 170km of The Line is a long-term goal, early segments and the luxury island of Sindalah will be operational or nearing advanced stages. This introduces a unique problem: inspecting vertical infrastructure. Traditional maintenance crews cannot easily abseil down a 500-meter mirrored facade to check for cleaning needs or structural stress. The Saudi Vision 2030 milestones for NEOM depend on autonomous aerial systems, drones that scan the exterior continuously, detecting defects without human risk. Furthermore, the energy infrastructure powering these zones must be flawless. NEOM’s commitment to 100% renewable energy means that solar farms and wind turbines must operate at peak efficiency. Dust accumulation or a single damaged blade can disrupt the energy grid. Manual inspection in the desert heat is inefficient. Autonomous drones will become the primary inspectors, ensuring the city of the future remains powered. II. Red Sea Global: The Coastal Challenge The Red Sea destination is moving fast. After the opening of the first resorts in 2024 and 2025, the year 2026 sees the expansion of Shura Island, with eight additional resorts slated for completion. This shifts the focus to marine integrity. Hotels sitting over the water and subsea assets face constant corrosion and biofouling. Maintaining the pristine nature of these sites is non-negotiable. This requires robotic inspection, ROVs underwater, and drones in the air to monitor the environment and the assets simultaneously without disturbing the ecosystem. The Saudi Vision 2030 milestones here are about balancing luxury with ecology. Any leak or structural failure could damage the coral reefs that attract tourists. Therefore, the inspection technology must be non-intrusive and highly accurate. III. Qiddiya City: The Entertainment Challenge Qiddiya City has announced that its flagship theme park, Six Flags Qiddiya, will open on December 31, 2025. This makes 2026 its first full year of operations. This is a massive milestone. The park features record-breaking rides like Falcons Flight. The safety requirements for such high-performance machinery are extreme. Managers cannot rely on slow, manual checks for rides that travel at 250 km/h. They need real-time structural health monitoring. Drones equipped with high-zoom cameras and thermal sensors can inspect the high tracks of roller coasters before the park opens each day. They can verify that every bolt and weld is secure. This ensures that the thrill remains safe, protecting the reputation of the Kingdom’s entertainment sector. IV. Diriyah and Urban Heritage In Riyadh, the Diriyah Gate project continues to expand. By 2026, new luxury hotels like the Aman Wadi Safar are expected to open. This project is unique because it blends modern luxury with delicate mud-brick heritage architecture. The maintenance challenge here is preservation. Heavy cleaning equipment or standard industrial inspection tools might damage the historic surfaces. Drones offer a “touchless” inspection method. They can scan the heritage sites to detect water damage, erosion, or structural shifts to the millimeter without ever physically touching the ancient walls. This preserves the history while ensuring the safety of the modern guests inside. The Operational Tech Stack How do we manage assets of this complexity? The answer lies in the “Digital Handover.” We must carry the high-precision data collected during construction into the operational phase. V. From BIM to Digital Twin During construction, we used drones to create precise BIM (Building Information Modeling) files to guide the builders. In 2026, this data transforms into a Digital Twin. This is a live, virtual replica of the city. When a drone inspects a building in 2026, it updates the Digital Twin. Facility managers can sit in a control room and see the exact condition of a solar panel or a water pipe in 3D. They don’t just see a maintenance ticket; they see the asset’s history and its future. For example, if a drone detects a crack in a facade at The Line, the Digital Twin can instantly show the managers what materials are needed for the repair, how to access the area safely, and how critical the damage is. This speed of information is vital for maintaining the seamless experience promised by Vision 2030. VI. Autonomous “Smart” Inspection (Low Altitude Economy) Manual maintenance cannot scale to meet Saudi Vision 2030 milestones. There are simply too many assets and not enough inspectors. The future is the low altitude economy. Imagine autonomous drone docks

Economy under 1,000 Feet: The Rise of LAE in Smart Cities

The Next Industrial Airspace Layer We often look at the sky and see empty space. However, a quiet revolution is happening just above our heads. This is the rise of the low altitude economy (LAE). This term refers to a new economic and operational domain occupying the airspace below 1,000 feet. It represents the next frontier for industrial efficiency. Global industries are moving fast. They are digitizing their airspace and adopting unmanned systems to perform autonomous inspections. This shift is not just a global trend; it is a critical component of Saudi Arabia’s Vision 2030. The Kingdom is building smart cities and transforming its industrial base. These massive projects require accurate, safe, and continuous aerial operations. Traditional ground methods cannot support this scale. The low altitude economy and industrial applications provide the only viable solution to manage these large-scale assets efficiently. Core Technologies Enabling the LAE To make this new economy work, we need a robust technological foundation. The LAE relies on a stack of advanced systems that ensure safety and predictability. I. The Technological Stack for Safe Operations Unmanned Traffic Management (UTM): We cannot have drones flying blindly. UTM acts like air traffic control for drones. It coordinates airspace, ensures compliance, and prevents collisions. BVLOS Frameworks: Real value comes when drones fly Beyond Visual Line of Sight (BVLOS). This framework establishes safe corridors for drones to operate over long distances, such as along pipelines, utility grids, and coastal zones. Autonomous Drone Stations: Efficiency demands persistence. Autonomous docking stations allow drones to land, charge, and deploy 24/7 without a human pilot on site. Remote Sensing Toolkit: The drone is just the carrier. The value lies in the sensors. We use LiDAR for depth, thermal imaging for heat detection, multispectral sensors for vegetation analysis, and methane detectors for gas leaks. Geospatial Data Infrastructure: All this data must go somewhere. We build high-resolution maps and GIS databases. These form the basis of digital twins, allowing operators to manage physical assets in a digital space. These systems interact seamlessly. They create a predictable and scalable workflow that transforms low altitude economy and industrial applications from a concept into a daily operational reality. Transforming Critical Sectors The application of this technology transforms how we manage the three pillars of modern society: Energy, Utilities, and Urban Development. II. Energy Sector Applications The energy sector demands the highest level of safety and monitoring. Pipeline Integrity: Drones monitor the Right-of-Way (ROW) along vast pipeline networks. They detect leaks and security breaches instantly, protecting the environment and the asset. Flare and Tank Inspection: We replace dangerous manual climbing with drone inspections. Drones perform visual, thermal, and Ultrasonic Thickness (UT) checks on flare stacks and storage tanks. This assesses corrosion and wall health without shutting down operations. Sustainability: Specialized sensors quantify methane and Greenhouse Gas (GHG) emissions. This data helps energy companies meet strict regulatory compliance and sustainability goals. III. Utilities and Power Infrastructure Grid reliability is non-negotiable. Drones ensure the lights stay on. Powerline Inspection: Drones capture high-resolution visual and thermal images of powerlines. LiDAR sensors measure the sag of the lines with centimeter precision. Vegetation Management: Overgrown trees cause outages. Drones analyze vegetation encroachment, allowing utility companies to trim trees only where necessary. Renewable Assets: As the Kingdom adopts green energy, drones inspect solar PV panels for dead cells and wind turbines for blade damage, ensuring maximum energy output. IV. Urban Development and Smart Cities Smart cities like NEOM require smart construction data. Digital Twins: Drones capture data to build 3D city models. These Digital Twins allow planners to simulate traffic, weather, and energy usage before building anything. Progress Tracking: Megaprojects move fast. Aerial surveys track construction progress day by day. This helps project managers catch errors early and keep the project on schedule. Environmental Monitoring: Sensors on drones monitor air quality and heat islands in urban areas. This data helps city planners design cooler, healthier living spaces. Accelerating Efficiency and Adoption The shift to the low altitude economy and industrial applications is not just about technology; it is about business results. V. Why LAE Accelerates Efficiency Cost and Frequency: Automated drones inspect assets more frequently at a lower cost. You can inspect a site daily instead of monthly. Human Safety: We remove humans from high-risk environments. No more climbing towers or entering confined tanks. Real-Time Data: Reports arrive in near real-time. This integration with enterprise systems allows for faster decision-making. National Scale: This technology supports cross-sector interoperability. Data collected for a road project can also help utility companies, supporting national-scale digital initiatives. VI. Pathway to Adoption Governments and industry operators must act now to build this ecosystem. Establish Readiness: Organizations must prepare their technical systems for BVLOS and UTM-aligned operations. Deploy Autonomy: Install autonomous drone stations to enable routine, high-frequency missions. Centralize Data: Build repositories to unify survey and inspection data. Start Pilots: Conduct pilot programs with measurable KPIs to prove the value. Ready to transform your low altitude economy energy, utility, or urban development projects? Let’s realize it through advanced sensing, processing, and data management platforms.

Integrated Aerial, Terrestrial, and Marine Inspection Framework for Industrial Asset Integrity

The Three-Dimensional Integrity Challenge Managing major infrastructure from long-distance pipelines and highways to offshore oil facilities, is a massive task. Asset owners in the MENA region face the immense challenge of maintaining structural health across all three major environments: air (high-altitude assets), land (linear corridors), and sea (submerged foundations). The traditional approach to managing these assets is severely flawed. Manual surveys on land, reliance on dangerous scaffolding or rope access in the air, and sending human divers into dark, high-risk waters (Sea) are slow, dangerous, and create fragmented data. This leaves asset owners vulnerable to unexpected failure and huge repair costs. Modern asset management demands a unified solution. It requires a specialized, robotic approach capable of performing objective, centimeter-accurate inspections in every domain. This necessary shift leads to the core of our strategy: full-spectrum asset inspection, utilizing specialized robotics and sensors to create one unified source of truth for the entire asset portfolio. The Land and Air Domains The beginning of the full-spectrum approach focuses on digitizing the vast surfaces of land and the complex vertical structures above ground. I. Land Inspection: Mapping the Foundation and Corridor Land assets including highways, pipelines, and industrial facilities, suffer from time delays and difficult access points during inspections and surveys. We overcome these challenges through integrated geospatial and robotic solutions. LiDAR and Photogrammetry: We use integrated aerial LiDAR systems to create the accurate Digital Terrain Model (DTM) needed for precise road and pipeline routing. Photogrammetry then provides the necessary high-resolution visual context. This initial Topographic Mapping is crucial for checking and verifying design against reality before construction proceeds. External Land Inspection: For inspecting rough terrain, checking pipeline integrity, or navigating hazardous ground areas beneath equipment (under-skids), we deploy advanced Deep Robotics platforms. These specialized ground robots access dangerous environments that are too unstable or confined for human inspectors, performing detailed visual and non-contact checks on assets. Internal Land Access (Confined Space): Even internal land structures like large ducts, vessels, or complex pipes require checks. For these challenging spaces where GPS signals fail, we use the Terra Xross 1 drone. This protected, cage-equipped drone flies safely inside these vessels, collecting high-resolution visual data to check for corrosion and structural issues, eliminating the need for human entry into hazardous atmospheres. Application: This combined data flow is used for rapid Topographic Mapping, volumetric analysis (earthwork optimization), and early design validation through BIM Integration. II. Aerial Inspection: Vertical Structures and Confined Spaces Vertical industrial structures from flare stacks and high piping to storage tanks present significant height risks. Our aerial inspection minimizes human exposure while delivering precise Non-Destructive Testing (NDT). Vertical NDT (Contact Inspection): For vital contact-based measurements, we deploy the Voliro T drone. This specialized aerial robot performs external, contact-based UT (Ultrasonic Thickness) Inspection and thermal scanning on challenging vertical and overhead assets, like tank walls and high piping. The Voliro T applies the stable force required to take precise thickness readings, verifying material integrity. High-Altitude Visual: We use standard industrial drones to perform rapid, high-resolution visual inspection of tall structures, roofs, and large-area piping, quickly identifying general wear or coating failure. Internal Safety (Confined Space): In large industrial vessels and tanks, the Terra Xross 1 drone ensures internal visual checks are performed safely and efficiently, further reducing personnel risk in hazardous, enclosed environments. The Sea and Synthesis Domains The third dimension of inspection, the marine environment is the most challenging. Successfully integrating this data creates the core of the predictive strategy. III. Sea Inspection: Qysea W6 NAVI for Coastal Resilience The safety risks, limited visibility, and time constraints of human divers make robotic inspection non-negotiable for subsea assets. Problem Solved: Our solution eliminates diver risk, time constraints, and low data quality in subsea environments. The Technology (W6 NAVI): We utilize the Qysea Maritime ROV W6 NAVI as the precision platform for underwater inspection. This compact, robust ROV is designed for stability and advanced data acquisition in open sea and port environments. Key Capabilities (W6 NAVI): The W6 NAVI provides several vital functions: Precision Navigation: It achieves enhanced hovering stability even in high currents, which is essential for accurate data collection near structures. Robust Surveys: It supports continuous, automated survey paths for consistent, repeatable data acquisition. Sonar and Payloads: It utilizes specialized scanning sonar to navigate in zero visibility conditions and carries modular payloads, including those necessary for subsea NDT and structural measurement. Application: The W6 NAVI is critical for inspecting subsea pipelines, performing scour assessment (foundation erosion) around jetties, and checking hull integrity. IV. The Predictive Synthesis: The Full-Spectrum Digital Twin The strategic value of full-spectrum asset inspection is realized by merging the data from all three domains (air, land, sea) into one cohesive, predictive platform. Data Fusion: We combine the DTMs (Land), the UT measurements (Air), and the sonar/scour data (Sea) into a unified dataset. The Digital Twin: This unified dataset creates the Digital Twin, a living, virtual replica of the entire asset portfolio. This advanced digital model allows asset managers to move beyond simple mapping and into true simulation. Value and RUL: The Digital Twin enables managers to perform remaining useful life (RUL) calculations and simulate future structural degradation. This unified approach provides objective, predictive maintenance insights, allowing clients to replace emergency spending with proactive, optimized resource allocation across the entire asset portfolio. Securing Integrity and Leadership The transition to a digital, holistic inspection strategy is essential for securing operational longevity and supporting Vision 2030’s infrastructure goals. Implement a full-spectrum asset inspection strategy of your infrastructure for long-term safety, efficiency, and predictive control. Let’s Talk!

ROV-Based Monitoring for Marine Infrastructure and Coastal Inspection Assets

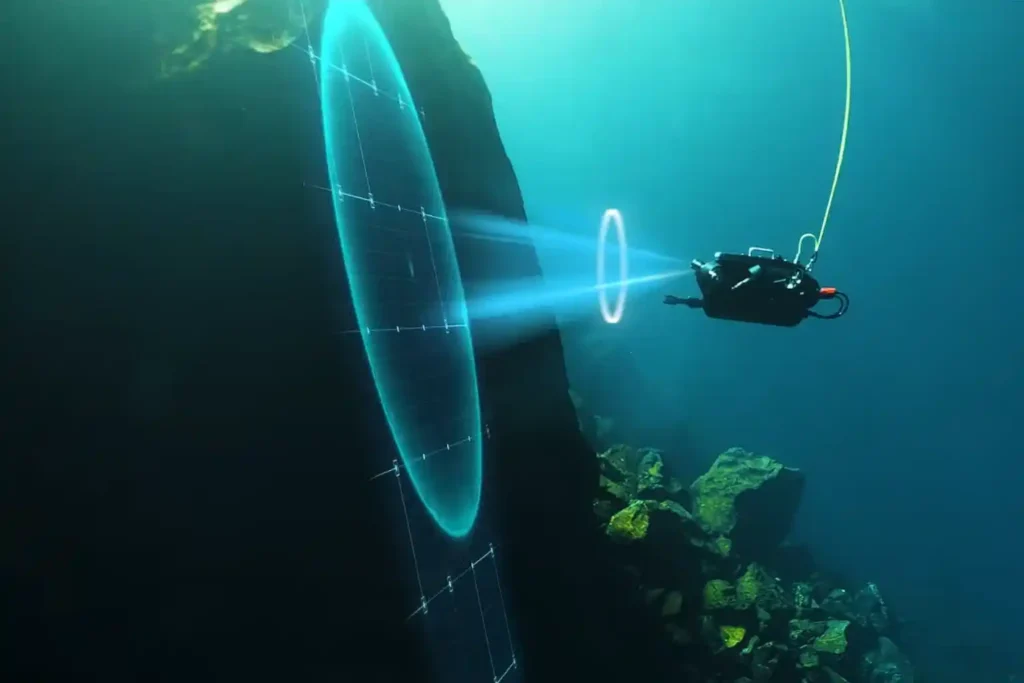

The Challenge Beneath the Surface The foundations of the MENA economy—jetties, bridges, seawalls, port facilities, and offshore energy platforms—rely on submerged infrastructure. These assets face a brutal, unseen enemy: the marine environment. Constant exposure to seawater, which is highly corrosive, leads to material loss. This structural decay is worsened by biofouling—the rapid growth of marine organisms that attach to surfaces and accelerate corrosion. These environmental stressors lead to structural fatigue and threaten the longevity of vital infrastructure. The traditional approach to inspection only compounds the problem: Safety, Risk, and Accessibility: Inspecting submerged assets typically requires human divers. This process is inherently risky due to high currents, low visibility, and deep or confined spaces. Human divers are physically limited in depth and endurance, restricting their bottom time to one or two hours. High Cost and Downtime: Diver-based inspections are costly and time-consuming, requiring extensive coordination and specialized teams. For assets like fuel tanks, inspection often requires draining the tank, halting operations, and causing significant revenue loss. Data Quality: Diver reports are often subjective, lack precise location data (geotagging), and are difficult for engineers to rely on for long-term predictive models. The region urgently needs a safer, more efficient, and data-driven way to manage its critical maritime assets. The Rise of ROV-Based Monitoring Remotely Operated Vehicles (ROVs) are robotic systems that are transforming underwater inspection workflows by eliminating the need for human presence in high-risk zones. This technology has moved from specialized offshore use to become the standard for routine ROV-based monitoring for marine inspection assets. I. Advanced Technologies for Unseen Environments Inspection-class ROVs are compact, agile, and equipped with a versatile sensor suite designed to overcome the limitations of the marine environment. Visual and Sonar Imaging: ROVs use high-definition cameras and bright LED lighting to provide unparalleled visibility in clear water. More critically, they carry multibeam or scanning sonar for navigation and imaging in areas with poor visibility, such as murky water or sediment-rich areas. Sonar emits sound waves to create a clear picture of the environment, even when the operator cannot see. Navigation and Positioning: Advanced systems leverage DVL (Doppler Velocity Log) and U-INS (Underwater Inertial Navigation System) to ensure stable control and precise positioning. This means the ROV can hover automatically in turbulent conditions and record the exact GPS coordinates of every finding (geotagging), allowing for easier data correlation later. Core Payloads: ROVs are modular and can carry essential tools, including laser scaling devices for precise measurement, environmental sensors (temperature, salinity), and Ultrasonic Thickness (UT) gauges for Non-Destructive Testing (NDT). II. Applications Across Marine Infrastructure ROV-based monitoring for marine inspection assets is suitable for virtually all submerged structures: Port Facilities and Jetties: ROVs inspect submerged concrete degradation, scour (erosion around foundations), joint separations, and piling integrity. Offshore Energy: They assess corrosion, marine growth, and cathodic protection anodes around platform jackets, risers, and offshore wind turbine foundations. Vessels and Confined Spaces: Shipowners use ROVs for underwater hull inspection and ballast tank checks, often eliminating the need for costly dry docking. Pipelines and Cables: ROVs perform routine checks for corrosion, sediment buildup, structural anomalies, and accurate depth-of-burial surveys. From Reactive to Predictive Maintenance The immediate deployment and continuous operation of ROVs transform asset care from a reactive, emergency response into a proactive, data-driven strategy. III. Enabling Proactive Asset Management Reduced Human Risk and Downtime: The primary gain is safety. ROVs operate in challenging conditions such as extreme depths, high currents, and contaminated waters, eliminating risks to human divers. Furthermore, ROVs can be deployed in minutes and operate continuously without the time restrictions of human divers, ensuring operational continuity. Quantitative Corrosion and Damage Assessment: Equipped with UT gauges, ROVs perform precise NDT, measuring wall thickness to determine corrosion and material loss. The data collected is highly traceable and auditable. Continuous Monitoring for Early Detection: The low cost and rapid deployment encourage more frequent inspections. This continuous monitoring allows owners to detect minor anomalies early, preventing small cracks or corrosion spots from escalating into severe structural failures. digital twin Integration: The high-resolution video, sonar images, and UT measurements are stored in cloud platforms like Terra 3D Inspect. This data builds and updates the asset’s digital twin, a virtual replica that allows managers to run simulations, forecast structural decay, and schedule maintenance precisely, maximizing the asset’s lifespan. IV. Synergy with Full Asset Visibility The underwater data is far more valuable when combined with aerial and terrestrial data. Our workflow integrates ROV bathymetry and scour data with drone LiDAR surveys of the dry dock and pier structures above the water line. This holistic approach provides complete, 360° asset visibility, moving beyond the subsea environment alone. Advancing Coastal Resilience with Smart Inspection The integration of remote technology is no longer optional; it is essential for supporting sustainable coastal and offshore infrastructure development under Saudi Vision 2030. Adoption Mandate: Organizations must adopt ROV-based monitoring for marine inspection assets as a cornerstone of their asset integrity programs. The cost benefits, avoiding drainage, reducing labor, and preventing downtime far exceed the cost of the technology itself, often providing a payback period of less than one year. Standardization and Integration: We encourage the integration of ROV data into existing GIS and digital twin systems for seamless lifecycle tracking. Partnering for Expertise: Terra Drone Arabia offers a complete suite of solutions, combining specialized expertise in subsea data acquisition with world-leading technology. We partner with innovators like QYSEA Technology to utilize ROVs (like the FIFISH Expert series) that are compact, maneuverable, and equipped with AI-enabled navigation and sonar systems. Our certified team ensures safe, efficient deployment and delivers actionable insights. Secure the long-term integrity of your marine assets. Contact us to discuss implementing an ROV pilot program and transforming your maintenance strategy from reactive to predictive.

Revolutionizing Corrosion Inspection With Drone-based Visual and UT Systems

The Corrosion Inspection Challenge Corrosion is the silent and relentless enemy of metal assets—remains the leading cause of unplanned shutdowns, containment failures, and devastating safety risks across the oil & gas, petrochemical, and heavy industrial sectors. In the demanding environments of the MENA region, assets like storage tanks, pipelines, and flare stacks face extreme pressure and must maintain peak structural integrity. The conventional methods for fighting corrosion are simply no longer good enough. Scaffolding and Time: Traditional inspections require extensive, costly scaffolding or rope access, shutting down operations for days or weeks. This severely impacts productivity. Safety Risks: Inspectors must enter hazardous confined spaces or climb hundreds of meters above the ground, exposing them to significant dangers. Manual Data: Manual Ultrasonic Thickness (UT) checks are subjective, slow, and often provide data that is difficult to trace and integrate into digital asset management systems. Industry urgently needs a safer, faster, and more data-rich way to assess asset health. The solution is the convergence of aerial technology and specialized testing: corrosion inspection with drone-based visual and UT systems. Integrating Visual and Ultrasonic Thickness (UT) Drones The future of asset integrity lies in non-contact aerial access combined with contact-based measurement precision. Drone technology now provides a complete, two-part inspection solution. I. High-Resolution Visual Inspection Visual drones start the process by quickly capturing comprehensive data on the asset’s exterior. Complete Coverage: Drones fly precise, automated paths around tanks, pipelines, and stacks, collecting high-resolution imagery. This imagery builds a precise 3D model (photogrammetry) of the asset. Defect Mapping: Specialized cameras detect and map all surface defects, such as paint degradation, coating loss, signs of external corrosion, and cracking. This creates a digital record showing the location and size of every visible fault. Efficiency Metric: By eliminating the manual setup time, drone technology can reduce the time required for complex tank or flare stack inspections by up to 95% compared to traditional scaffolding or rope access methods, delivering immediate time and cost savings. II. Drone Equipment Solution: The Hardware Behind the Data (New Section) Terra Drone Arabia delivers advanced results by operating both proprietary solutions and best-in-class specialized hardware designed for harsh industrial environments. Our fleet is purpose-built to execute both visual and contact-based NDT with exceptional stability and accuracy. A. Voliro T for Contact NDT For vital contact-based measurements, we deploy the Voliro T drone. Unique Design: The Voliro T is an aerial robotic platform uniquely engineered with omnidirectional flight capabilities and tiltable rotors. This allows the drone to approach vertical or overhead metal surfaces from any angle and apply stable, measurable force. UT Payload: The Voliro T, equipped with an Ultrasonic Transducer (UT) probe, performs precise, stable contact NDT. This specialized function is essential for accurate wall thickness measurement in high-altitude areas. B. High-Endurance Visual Platforms For long-range corridor mapping and initial high-resolution visual assessment, our inspection solutions rely on robust, enterprise-grade multirotor platforms. These systems carry high-resolution cameras and thermal sensors, enabling fast, safe visual coverage of vast industrial footprints and linear pipelines. C. Ultrasonic Thickness (UT) for Material Loss The crucial step for determining true structural integrity is measuring wall thickness. The Voliro T now performs this Non-Destructive Testing (NDT) task. Contact Measurement: The Voliro T drone carefully approaches the metal surface of the asset, be it the roof of a storage tank or a vertical wall—and gently places a contact sensor on the surface. This stable contact allows the Voliro T to measure the wall thickness from the outside. Corrosion Detection: By comparing this measured thickness to the original blueprint specification, we immediately detect corrosion and material loss. This confirms whether the asset remains structurally sound. Data Traceability: The UT reading is captured digitally, stamped with its exact GPS location, and immediately linked to a photograph of the contact point. This provides auditable data that meets the strict traceability requirements of industry standards. Technical and Operational Benefits Adopting corrosion inspection with drone-based visual and UT systems delivers clear, quantifiable advantages for safety, finance, and long-term planning. III. Technical and Operational Benefits of Drone NDT The fusion of aerial access and digital NDT transforms risk management into a strategic asset. A. Safety and Efficiency Gains Zero High-Altitude Risk: Drones like the Voliro T perform all inspections—from pipe racks to flare stack tips—without putting a single worker at risk of falling or entering a dangerous atmosphere. Minimal Shutdown Time: Drones perform inspections much faster, allowing facilities to maintain operational continuity. This significantly cuts downtime and maximizes productivity. This enhanced safety record supports ISO 45001 occupational health standards. Efficiency: Drone inspection missions are quick. When compared to the weeks needed for scaffolding, drone operations reduce inspection time by up to 70% for an asset, saving labor and rental costs. B. Accuracy and Predictive Maintenance Consistent Data: Drone flight paths are automated and repeatable. This ensures every inspection captures data from the exact same location as the previous one, providing reliable change detection over time. Traceable UT Data: Drone UT data is recorded with precise GPS location and photo documentation, providing level 3 traceability that meets API 653 standards, which governs above-ground storage tank inspection. This removes the subjectivity often found in manual reports. Digital Twin Integration: All visual maps, defect locations, and UT thickness measurements are immediately integrated into the asset’s digital twin. This living replica allows managers to perform predictive maintenance and accurately calculate the asset’s remaining useful life (RUL). C. Compliance and Standardization The use of drone technology supports major regulatory frameworks, ensuring structural integrity compliance. Integrity Standards: Drone NDT techniques support inspection requirements under standards such as API 653 (Storage Tanks) and ISO 9712 (Qualification of NDT Personnel). Standardization: As drone technology matures, collaborating with inspection bodies helps standardize these UAV-based NDT workflows, securing the technology’s place as a primary integrity tool. Toward Intelligent Corrosion Management The era of slow, dangerous, and subjective industrial inspections is ending. The high-resolution, centimeter-accurate data delivered by corrosion inspection with drone-based visual and UT systems is the central component of intelligent asset management strategies

Advancing Geospatial Intelligence for Smarter Cities and Infrastructure

Saudi Arabia is building the future, investing heavily in monumental projects like NEOM, The Line, and Red Sea Global. These megaprojects carry an immense price tag and an equally immense demand for speed and precision. However, construction starts with Topographic Mapping, and here lies a critical problem. Conventional surveying methods, which rely on manual teams and old technology, cannot keep up with these unprecedented timelines. These traditional approaches, using physical measuring tools and manual GPS are slow, costly, and inherently risky for the workers. Surveying a large industrial area can take a project six months just to gather the initial ground data. This unacceptable delay severely hampers the entire construction schedule. These megaprojects cannot afford a long “time-to-data” lag. They urgently need a solution that can accelerate the process, minimize risk, and deliver data instantly. This transformation requires a complete overhaul of how data is gathered and used. This urgent need for high-quality information is the driving force behind the demand for Geospatial Intelligence for Smart City development. This strategic challenge requires a transformative solution: modern Geospatial Intelligence for Smart City platforms. The Reality Capture Revolution: Drones as the Geospatial Engine The only way to break the six-month bottleneck and meet the aggressive timelines of Vision 2030 is through Drone-Based Reality Capture. This technology has moved past being a niche tool; it is now the essential geospatial engine for all major infrastructure development in the region. Drones, equipped with advanced sensors, capture millions of data points per second from the air. This aerial perspective allows specialized providers like Terra Drone Arabia to completely bypass the physical limitations of ground teams. By replacing manual processes with automated flight paths and rapid data acquisition, we drastically reduce the time spent in the field. This revolutionary approach allows us to overcome the time-to-data constraint, successfully achieving up to a 50℅reduction in the time needed for initial topographic surveys. This speed does not come at the cost of accuracy. Instead, the density and resolution of the captured data surpass what manual methods can deliver. This efficient data collection process ensures that every project starts with a perfect, verifiable digital foundation. This Geospatial Intelligence for Smart City planning gives engineers the confidence they need to start design and construction faster. LiDAR vs. Photogrammetry: Capturing Reality in High-Fidelity Effective reality capture for these multi-billion-dollar projects relies on the combined power of two complementary sensing technologies: LiDAR and Photogrammetry. Neither technology alone provides the complete picture; their integration is what delivers high-fidelity Geospatial Intelligence for Smart City development. LiDAR: The Geometric Scanner Function: LiDAR (Light Detection and Ranging) is an active sensor that sends millions of laser pulses to the ground, precisely measuring the distance and elevation. Value: This technology is essential for generating the bare-earth geometry of the terrain. Critically, LiDAR pulses can penetrate through light vegetation and foliage. This means that even in areas with trees or scrub, engineers receive an accurate Digital Terrain Model (DTM), which is impossible to achieve efficiently with camera-based surveying. Proprietary Edge: Using proven systems like Terra LiDAR One gives us precise control over the data quality, ensuring the geometric integrity required for detailed civil engineering design. Photogrammetry: The Visual Engine Function: Photogrammetry captures thousands of high-resolution, overlapping images using a camera. Software stitches these images together to create a visual, textured 3D model and a seamless Orthomosaic Map. Value: This process delivers the rich visual texture and realistic context needed for stakeholder communication and detailed visual review. The Orthomosaic Map is a geometrically corrected, true-to-scale visual record of the entire site. Accuracy Assurance: When performed with an RTK (Real-Time Kinematic) drone, the data is accurately positioned at the centimeter level, ensuring that the visual map perfectly aligns with the LiDAR geometry. Building the Living Digital Twin: The Foundation for Smart Operations The ultimate goal of gathering all this high-fidelity data is not just to create maps, but to create a Digital Twin. This Digital Twin is a complete, virtual replica of the physical highway, city, or industrial plant. Centimeter-accurate, drone-captured data is the essential, living foundation for these digital twins. The data allows engineers to move beyond static planning documents and into a dynamic, simulated environment. Simulating the Future: Once the Digital Twin is built with perfect geometry, city planners and asset managers can use it to simulate real-world events. They can test how a new drainage system performs during a flash flood or predict how pavement will degrade under different traffic loads Managing Complexity: For large, interconnected projects like NEOM, the Digital Twin acts as a command center. It integrates live data from sensors, construction progress updates, and maintenance schedules into a single, comprehensive view. This ensures all parts of the future smart city operate cohesively and efficiently. The foundation of this system is robust, up-to-date Geospatial Intelligence for Smart City development. From Planning to Integrity: Applications Across the Project Lifecycle The value of high-quality Geospatial Intelligence for Smart City projects is realized across every single phase of development, offering measurable time and cost savings. Pre-Construction: Accelerating Earthwork Rapid Topography: Initial drone surveys quickly deliver the DTM and high-resolution contour maps required to commence engineering design, drastically shortening the project’s planning phase. Earthworks Optimization: The precise DTM data allows for accurate Volumetric Analysis and Cut-and-Fill calculations. This means contractors know exactly how much soil to move, preventing expensive guesswork and optimizing material logistics. BIM Integration: Survey data integrates immediately into the Building Information Modeling (BIM) software, accelerating the design timeline and allowing for immediate clash detection. Construction: Monitoring and Quality Control Real-time Monitoring: Drones fly frequent, automated missions to track physical progress against the project schedule. This creates an objective, time-stamped record of construction for transparency and contract validation. Design Compliance: The captured 3D models are digitally compared to the original design plans. This allows site managers to catch conflicts and discrepancies early, reducing costly rework. Post-Construction: Infrastructure Integrity Structural Health Checks: Drones perform non-contact integrity checks on critical assets. They fly beneath bridges or around

From Survey to Digital Twin: The Technical Roadmap for Drone-Powered Highway Construction.

The vast, intricate road and highway network is the undisputed backbone of the modern economy, especially across the swiftly developing MENA region. These vital transportation arteries, which stretch across great distances, face constant challenges: rapid material breakdown from harsh climates, ceaseless heavy traffic, and the severe safety risks tied to manual maintenance. Inspecting and caring for these complex, linear assets—like elevated bridges and long corridors is a monumental logistical and safety puzzle. This immense responsibility calls for a fundamental shift: moving away from slow, expensive, and dangerous reactive maintenance toward intelligent, predictive asset care. The critical step in this transformation is the aerial perspective provided by Unmanned Aerial Systems (UAS) drones. Drones are now essential for modern infrastructure management because they offer unparalleled speed, high data accuracy, and enhanced personnel safety. This comprehensive editorial explores how drone technology provides immediate and lasting value across the entire infrastructure lifecycle, establishing a new, safer, and faster benchmark for highway inspection. The Infrastructure Imperative The economic stability and long-term safety of the Kingdom and the wider region depend heavily on keeping the transportation network sound. However, managing this immense asset base using traditional, manual methods is no longer a viable option. Manual inspection requires costly actions like closing traffic lanes, renting expensive equipment like scaffolding and cherry pickers, and, most critically, forcing human inspectors into high-risk zones, such such as elevated bridges or areas with heavy, fast-moving traffic. This old way is slow, dangerous, and extremely inefficient. The solution is digital, objective, and non-contact. The drone’s core strength is providing a detailed, repeatable aerial view, transforming the slow, dangerous process of highway inspection into a fast, digital, and fully auditable workflow. The total benefit of drone use touches every phase of a highway’s life from the initial blueprint to decades of operation. The Foundation and The Build The application of drone technology begins the moment a new road is planned, guaranteeing that the project starts with a perfect, high-quality digital foundation. I. Precision Mapping for New Design and Rehabilitation The initial phase of any highway project—whether building new roads or overhauling existing ones is the most critical for budget and safety. Drones transform this process from a guesswork exercise into a fully transparent, digitally integrated workflow. A. LiDAR for Digital Terrain Modeling (DTM) and Subsurface Integrity For linear infrastructure like highways, precise terrain data is non-negotiable. LiDAR systems provide the superior geometric accuracy needed for civil engineering design. The Technical Edge: Bare-Earth Penetration Pulse Technology: Our drone-mounted LiDAR systems are active sensors that emit millions of laser pulses per second, measuring distance by recording the time a pulse takes to return. This creates a high-density, three-dimensional point cloud. DTM Generation: The key technical advantage is the LiDAR’s ability to record multiple returns per laser pulse. This allows the system to effectively filter out surface features like scrub, trees, or construction debris, isolating the true ground elevation to create an accurate Digital Terrain Model (DTM). This DTM is the essential foundation for calculating road drainage, slope stability, and horizontal alignment. Corridor Integrity: This geometric data is used to identify precise gradient changes, define the critical right-of-way boundaries, and spot potential geological hazards along the lengthy highway corridor. Geometric Accuracy and Quality Assurance Centimeter Precision: High-end LiDAR and GNSS systems ensure the data is collected with centimeter-level accuracy, which is a requirement for 1:500 scale engineering surveys. Subsurface Modeling: The initial survey data is also essential for integrating follow-on data, such as utility maps created through Ground Penetrating Radar (GPR). This provides a complete 3D picture of any existing underground utilities (cables, pipelines) that could conflict with the new highway design. B. Photogrammetry for Visual Accuracy and Design Integration While LiDAR provides the geometric skeleton, photogrammetry supplies the visual texture and facilitates crucial digital checks against the design. Creating the Auditable Orthomosaic RTK Geo-referencing: Drones capture thousands of high-resolution, overlapping images that are processed into a single, seamless Orthomosaic Map. This map is geometrically corrected and precisely aligned using RTK (Real-Time Kinematic) positioning, ensuring the visual data is just as accurate as the LiDAR geometry. Visual Documentation: The Orthomosaic Map becomes the primary visual record for the project, showing existing infrastructure, land use, and site conditions without distortion, which is key for engineering review. Digital Integration and Error Mitigation BIM/CAD Workflow Acceleration: The processed photogrammetry and LiDAR data are immediately converted into formats that integrate seamlessly into BIM (Building Information Modeling) and CAD software. This direct flow minimizes the manual transcription errors common in legacy surveying. Design Validation: Engineers use the high-fidelity aerial data to overlay the planned highway design model onto the actual terrain data. This Drone-BIM integration has been shown to reduce design errors by up to \mathbf{65\%}, allowing teams to catch conflicts and discrepancies early, which saves massive amounts of money and time during the earthwork phase. Volumetric Analysis: The accurate digital elevation models (DTMs) are used for precise cut-and-fill analysis and material stockpile measurements, ensuring material logistics are optimized and budgets are strictly controlled. II. Quality Control and Earthwork Efficiency During Construction Once construction is active, drones become the project manager’s most reliable auditing tool, ensuring work meets the required quality and safety standards. A. Earthwork and Volumetric Analysis Accurate earthwork calculation is fundamental to controlling costs and material flow in highway construction. Cut-and-Fill Analysis: Frequent, automated drone flights capture 3D models used for precise cut-and-fill measurements and stockpile analysis. This ensures material logistics are optimized and prevents expensive overages or material shortages. Rework Mitigation: This high-resolution data ensures that the ground surface is prepared perfectly and aligns with design specifications before expensive asphalt paving begins. By feeding this up-to-date aerial survey data into digital models, Drone-BIM integration has been shown to reduce design errors by up to $\mathbf{65\%}$, significantly cutting down on rework. B. Real-Time Progress Monitoring and Safety Progress Tracking: Drones generate up-to-date 3D models to track physical progress against project milestones. This creates a reliable, objective, and visual timeline of the construction process. Site Safety: Drones quickly

Revolutionizing Land Surveying with Drone Photogrammetry and LiDAR Integration

The foundational work of building Saudi Arabia’s next-generation cities from the coastal developments of Red Sea Global to the vast infrastructure of NEOM begins with a single critical step: land surveying. This core discipline, often taken for granted, is the very first factor dictating a project’s timeline and budget. Yet, the relentless pace and massive scale of Vision 2030 demand an impossible standard that traditional methods simply cannot meet. We have reached a pivotal moment where efficiency must fuse with unprecedented accuracy. The industry’s solution lies in the intelligent adoption of uncrewed aerial systems (UAS), ushering in the new age of digital geospatial capture. As technical leaders in the Middle East, Terra Drone Arabia recognizes that the future of infrastructure hinges on the seamless integration of Drone Photogrammetry and LiDAR Integration, a potent combination that is fundamentally transforming land surveying from a logistical challenge into a competitive advantage. The Shift Toward Drone-Based Land Surveying The foundational work of building Saudi Arabia’s next-generation cities from the coastal developments of Red Sea Global to the vast infrastructure of NEOM begins with a single critical step: land surveying. A. The Technical Failure of Legacy Systems For decades, Land Surveying relied on the painstaking work of field teams armed with terrestrial sensors. These conventional methods—principally Total Stations (TS) and network-based GNSS rovers—provided high point-accuracy but were inherently constrained by scale and terrain. For large-scale projects, this legacy system introduces severe technical limitations: Data Resolution and Density Bottleneck: Traditional methods rely on discrete point measurements. A surveyor manually chooses a point to measure, meaning the resulting Digital Terrain Model (DTM) or Digital Surface Model (DSM) is built from a relatively sparse dataset. This inherent lack of data density often proves insufficient for the millimetre-accurate BIM (Building Information Modeling) and complex CAD integration now mandated for modern giga-projects. The limited resolution makes automated clash detection and volumetric analysis key steps in Industry 4.0 workflows difficult or impossible. Geometric Inaccuracy in Obscured Terrain: Ground-based techniques struggle immensely with terrain changes obscured by vegetation, steep slopes, or areas with frequent shadow cover. Total Stations require line-of-sight, forcing multiple, time-consuming setups. For coastal projects requiring high-fidelity cliff or shoreline mapping, this presents a significant geometric challenge and a safety risk. Chronological Data Lag: The intensive manual labor required to cover a 10-square-kilometer site means the project’s foundational topographic data is often compiled over weeks or months. This chronological data lag creates a critical disparity between the existing ground truth and the digital model being used for design and earthworks calculation, leading to inevitable, costly rework downstream. The Time-to-Data Crisis Ultimately, the logistical complexity high manpower, extensive safety planning, and the sheer time required for sequential, manual data capture forces project managers into a six-month waiting period for their foundational topographic base. This systemic lag time is incompatible with the strategic vision of Saudi Arabia, where giga-projects require real-time validation and accelerated decision-making. B. The Geospatial Mandate: Digitalization as a Non-Negotiable The sheer scale of projects like NEOM, Qiddiya, and Red Sea Global—where areas span hundreds of kilometers and deadlines are non-negotiable—demanded a technological solution that could capture and process data instantaneously and comprehensively. The global industry migration to UAS is driven by quantifiable engineering benefits: UAS Platforms for Extended Coverage: Robust enterprise platforms like the DJI Matrice 400 (M400) provide long endurance (up to 59 minutes of flight time) and RTK accuracy, enabling single-flight coverage that compresses months of manual work into hours. The M400 is ideal for lengthy or remote surveying missions due to its extended flight time and range. High-Density Reality Capture: The ability to deploy non-contact sensors either active (LiDAR) or passive (Photogrammetry) collects data at a density measured in millions of points per second. This shift from sparse, manual points to high-density point clouds is the key technical enabler for creating the accurate, living geometric foundation necessary for a true Digital Twin. Mitigation of Safety Risk: By eliminating the need to put personnel on steep embankments, near active machinery, or within hazardous site zones, drone-based land surveying inherently complies with the strict ISO 45001 (Occupational Health and Safety) standards upheld by major clients like Aramco. This urgent demand for fast, centimeter-accurate geospatial data to support BIM workflows, smart city planning, and environmental compliance has rendered traditional methodologies technically obsolete, making drone integration the essential strategy for modern land surveying. Understanding the Technology The transition to drone-based land surveying is defined by two primary technologies: Photogrammetry and LiDAR. While both deliver three-dimensional data, they operate on distinct technical principles, and understanding their complementarity is key to successful project execution. A. Technical Principles and Complementarity The art of effective Land Surveying lies not in choosing one technology, but in mastering the workflow that combines their strengths. Photogrammetry: The High-Resolution Visual Engine Principle: Photogrammetry works by capturing hundreds or thousands of high-resolution, overlapping aerial images of a target area. Processing software then uses complex algorithms to identify common points across these images, triangulating their positions to generate a dense 3D point cloud, a geo-referenced orthomosaic map, and textured 3D models. Accuracy: Modern enterprise systems, such as the DJI Matrice 400 paired with the Zenmuse P1 full-frame camera, use Real-Time Kinematic (RTK) or Post-Processing Kinematic (PPK) corrections. This GPS correction technique eliminates the majority of Ground Control Points (GCPs) and ensures the captured data is geo-referenced with extremely high precision. LiDAR: The Penetrating Geometric Scanner Principle: LiDAR (Light Detection and Ranging) is an active remote sensing technology. The sensor emits millions of laser pulses toward the ground. The time it takes for the pulse to return is measured, enabling the precise calculation of distance. The result is an immensely dense and highly accurate 3D point cloud. Advantage in Complexity: LiDAR excels in environments that defeat photogrammetry namely, areas with dense vegetation, complex utilities, or shadows. The Zenmuse L2 LiDAR, compatible with the M400, features superior penetration capabilities and can detect smaller objects with greater detail. Since a portion of the laser pulses can penetrate gaps in the canopy,

How Drones 2x Fastened Survey for Large Areas

Executive summary We delivered a coastal topographic map to support mangrove planning and environmental impact assessment across 102 km² split into 13 shoreline blocks in Jubail and Ras Al Khair. Field data collection finished in 1 month. Processing took 2 months. The program concluded in under 3 months end-to-end, significantly faster than a traditional coastal campaign. Why coastal topography is hard Shorelines introduce real operational friction. Access is limited. Safety risks rise. Above all, tide windows control when you can work and for how long, which stretches ground schedules and complicates repeatable measurements. A conventional approach in these conditions becomes slow and difficult. Method overview: hybrid LiDAR + photogrammetry We selected a hybrid workflow that combines airborne LiDAR for structure-through-vegetation and elevation fidelity with photogrammetry for high-resolution textures and planimetrics. This approach hits accuracy and coverage targets for coastal ecosystems, mangrove planning, and EIA deliverables. Platforms and control Control: High-grade GNSS using Trimble R12 for Primary Reference, GCPs used in adjustment, and ICPs held blind for validation and accuracy reporting. Multiplatform capture: DJI M350 RTK with Zenmuse P1 (imagery) and Zenmuse L2 (LiDAR) for flexible sorties over irregular shorelines. Trinity Pro with Sony LR-1 and Qube640 to extend corridor efficiency and coverage per flight. Acquisition strategy We divided the shoreline into 13 blocks and scheduled missions inside tide windows to balance safety and data quality. This playbook completed capture in 1 month and kept datasets comparable across sites despite changing coastal conditions. Processing workflow and QA Inputs included LiDAR point clouds, geotagged photos, and the full GCP/ICP set. We aligned and adjusted the block network, generated a DSM and bare-earth DTM, built the orthomosaic, and created contours and 2D CAD. We computed residuals on independent checkpoints and packaged the Accuracy Assessment and Survey Report for sign-off. Results that matter Time: Delivered in < 3 months, compared with a conventional estimate of ~ 6 months in this setting. Quality and efficiency: The program lists improved accuracy, faster turnaround, cost reduction, and increased safety as the primary benefits. Compliance: Topography is compliant with consultant standards and industry best practice, making it suitable for EIA workflows. Safety gain: We reduced tidal-zone exposure by eliminating most on-foot survey inside areas that flood at high tide. What stakeholders receive A complete, design-ready package: GCP and ICP coordinate lists, orthomosaic, DSM, DTM, contours, 2D CAD drawings, plus an Accuracy Assessment and Survey Report for traceability and sign-off. Implementation checklist Send AOI geometry, target scale, and contour interval, accuracy tolerances, CRS/vertical datum, relevant tide tables, and any permit constraints. This ensures that block planning, control layout, and compliance steps are implemented correctly the first time. Start Now Share your AOI and requirements. We will return a scoped plan with flight blocks, control layout, QA gates, and a delivery schedule aligned to your milestones. Included at no cost for kickoff: free 3-month progress monitoring with monthly milestone updates, QA-gate briefs, a simple status dashboard for field and processing stages, and a pilot block validation with a sample tile under NDA for early stakeholder review.

How Drone Topographic Mapping Captured 124 km² in 1 Month

Every decision in a sewer upgrade or drainage expansion depends on the fidelity of the ground surface you hand to designers. In a dense urban corridor next to an international airport, conventional total station and GNSS traverses face line-of-sight gaps and obstruction bias that create uneven accuracy and patchy coverage. That risk is real in North Jeddah, where the area of interest lies adjacent to the airport and spans built-up neighborhoods. Here is what surface truth looks like at the city scale. We captured a continuous 124 square kilometer topographic dataset in North Jeddah and delivered it as a CAD-ready package in under three months from kickoff. Field acquisition took one month. Processing took two months. This timeline gives engineers a single authoritative surface rather than stitched pockets of data collected over a long period. Surface truth is more than a pretty map. It is a defensible stack of products that design teams can trace. The deliverables included an orthomosaic for planimetrics, a Digital Surface Model and Digital Terrain Model for elevation control, contours, 2D CAD drawings, the full list of ground control and independent checkpoints, a documented accuracy assessment, and a formal survey report. These artifacts allow design leads to audit decisions and sign off with confidence. Accuracy management begins at acquisition. We flew an RTK-enabled drone platform with a full-frame photogrammetry camera and built a high-grade control network. A Trimble R12 receiver established and measured ground control points for adjustment and independent checkpoints for validation. This control strategy reduces reliance on interpolation and tightens both horizontal and vertical residuals across built-up corridors. The counterfactual underscores the stakes. A traditional approach across this environment would require multiple field teams for about three months and still lean on interpolation between sparse points. The drone-based program concluded the full scope in less than three months while improving accuracy and completeness for downstream CAD and hydraulics. This difference shortens design cycles and cuts rework for utility corridors and drainage upgrades. Dense Neighborhoods and Airport Constraints The area of interest covers 124 square kilometers in North Jeddah and sits adjacent to the airport, which makes both data capture and flight planning uniquely complex. Large coverage with airport proximity raises operational constraints, while dense neighborhoods create measurement blind spots for traditional crews. Airport-adjacent realities. In an airport environment, teams must plan flight lines to respect controlled airspace and safety buffers. You manage takeoff and landing zones carefully, maintain strict altitude profiles, and schedule sorties to minimize conflicts with traffic patterns. Geofencing unlocks, NOTAM checks, and close coordination with authorities are standard steps for this kind of work. The goal is predictable, repeatable acquisition without drift in GNSS solutions or interruptions to coverage. Built-up urban fabric. High building density, narrow corridors, and road canyons reduce line of sight for total stations and can introduce GNSS multipath for traditional rovers. That combination produces coverage gaps and uneven accuracy when you rely on sparse spot levels collected over long traverses. The case conditions explicitly note that built-up areas make conventional topographic surveys “very challenging” and time-consuming. Why an aerial approach fits this terrain. A drone survey and mapping workflow captures consistent overlap above obstacles and decouples the line of sight from ground constraints. With a DJI M350 RTK and Zenmuse P1 full-frame sensor, you can execute systematic blocks that maintain geometry across long corridors while tying everything to a robust control network. This approach improves continuity through tight streets and variable roof heights. Time pressure from scale. Because the 124 km² footprint is large and the timeframe is short, a ground-only campaign would require many teams for an extended period, yet still lean on interpolation between sparse points. The case estimates that a traditional approach could take about three months with multiple crews in this exact built-up context. Drone acquisition compresses the field schedule while maintaining fidelity for downstream design. What this environment demands from the dataset. To serve urban sewer design, the surface must be continuous across roads, intersections, and residential blocks near the airport. That means full orthomosaic coverage for planimetrics and elevation products that remain stable across building shadows and narrow corridors. These conditions are exactly why the project leveraged drone photogrammetry for the topographic survey requirement in this location. The Method: RTK Photogrammetry Built for Accuracy and Scale Objective and scope. The brief required a drone-based photogrammetry program to produce a topographic map for a groundwater sewer network design. We planned for city-scale coverage and design-ready outputs that engineers could trust. Control first. We began with a high-grade GNSS control strategy. A Trimble R12 established the Primary Reference Marker and measured both Ground Control Points for adjustment and Independent Checkpoints for validation. This gives us traceable horizontal and vertical control across built-up corridors where the line of sight is limited. Airframe and sensor. We executed an acquisition with a DJI M350 RTK paired to a Zenmuse P1 full-frame camera. RTK fixes stabilized camera center positions during flight, which improved the initial network geometry and reduced corrections downstream. Block design and sortie planning. We divided the 124 square kilometer area into flight blocks that respected airport proximity and dense neighborhoods. We set systematic flight lines to keep overlap consistent through narrow streets and variable roof heights, and we staged takeoff and landing zones to maintain safe operations. Acquisition window. Field capture finished in one month. This compressed window ensured consistent lighting and seasonal conditions across the entire mosaic, which reduces seams and radiometric variation. Photogrammetric processing. We ran a rigorous pipeline to turn imagery and control into design-ready surfaces: Import imagery and GNSS metadata, then perform initial alignment with RTK positions. Constrain the bundle adjustment with GCPs, while holding ICPs blind for an independent accuracy check. Generate dense point clouds, then derive the Digital Surface Model and bare earth Digital Terrain Model. Create the orthomosaic for planimetrics, followed by contours suitable for design at the requested scale. Export CAD-ready drawings and the coordinate lists for all control and checkpoints. Validation and QA. We